30 ADV100 • Quick installation guide - Specifications and connection

7.1.3 EMC guide line

The converters are protected in order to be used in industrial environments where, for immunity purposes, large

amounts of electromagnetic interference can occur. Proper installation practices will ensure safe and trouble-free

operation. If you encounter problems, follow the guidelines which follow.

- Check for all equipment in the cabinet are well grounded using short, thick grounding cable connected to a

common star point or busbar. Better solution is to use a conductive mounting plane and use that as EMC ground

reference plane.

- Flat conductors, for EMC grounding, are better than other type because they have lower impedance at higher

frequencies.

- Make sure that any control equipment (such as a PLC) connected to the inverter is connected to the same EMC

ground or star point as the inverter via a short thick link.

- Connect the return ground from the motors controlled by the drives directly to the ground connection (

) on the

associated inverter.

- Separate the control cables from the power cables as much as possible, using separate trunking, if necessary at

90º to each other.

- Whenever possible, use screened leads for the connections to the control circuitry

- Ensure that the contactors in the cubicle are suppressed, either with R-C suppressors for AC contactors or

‘ywheel’ diodes for DC contactors tted to the coils. Varistor suppressors are also effective. This is important when

the contactors are controlled from the inverter relay.

- Use screened or armored cables for the motor connections and ground the screen at both ends using the cable

clamps

Note! For further information regarding electro-magnetic compatibility standards, according to Directive 2004/108/EEC, conformity checks carried out on Gefran

appliances, connection of filters and mains inductors, shielding of cables, ground connections, etc., consult the “Electro-magnetic compatibility guide” on the

CD attached to this drive.

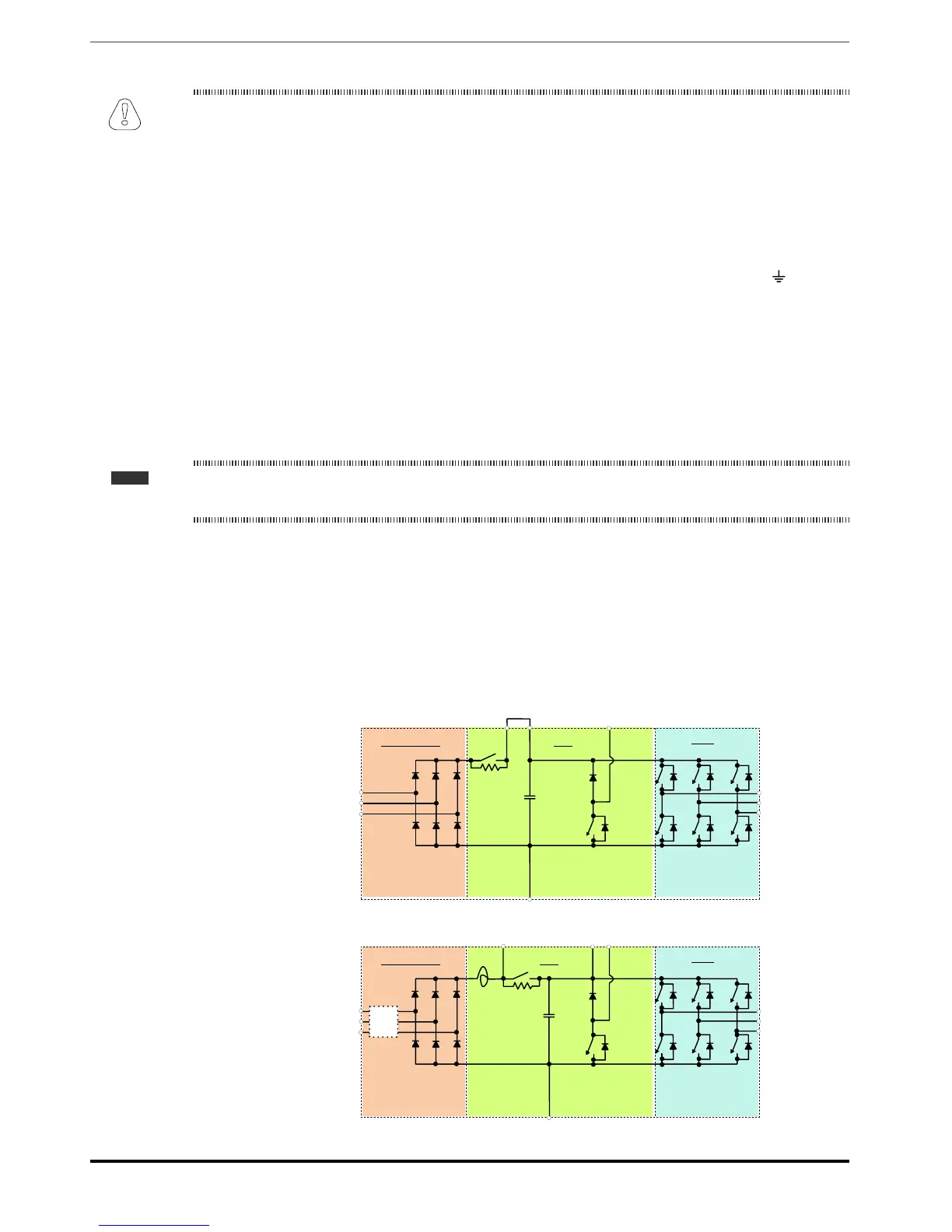

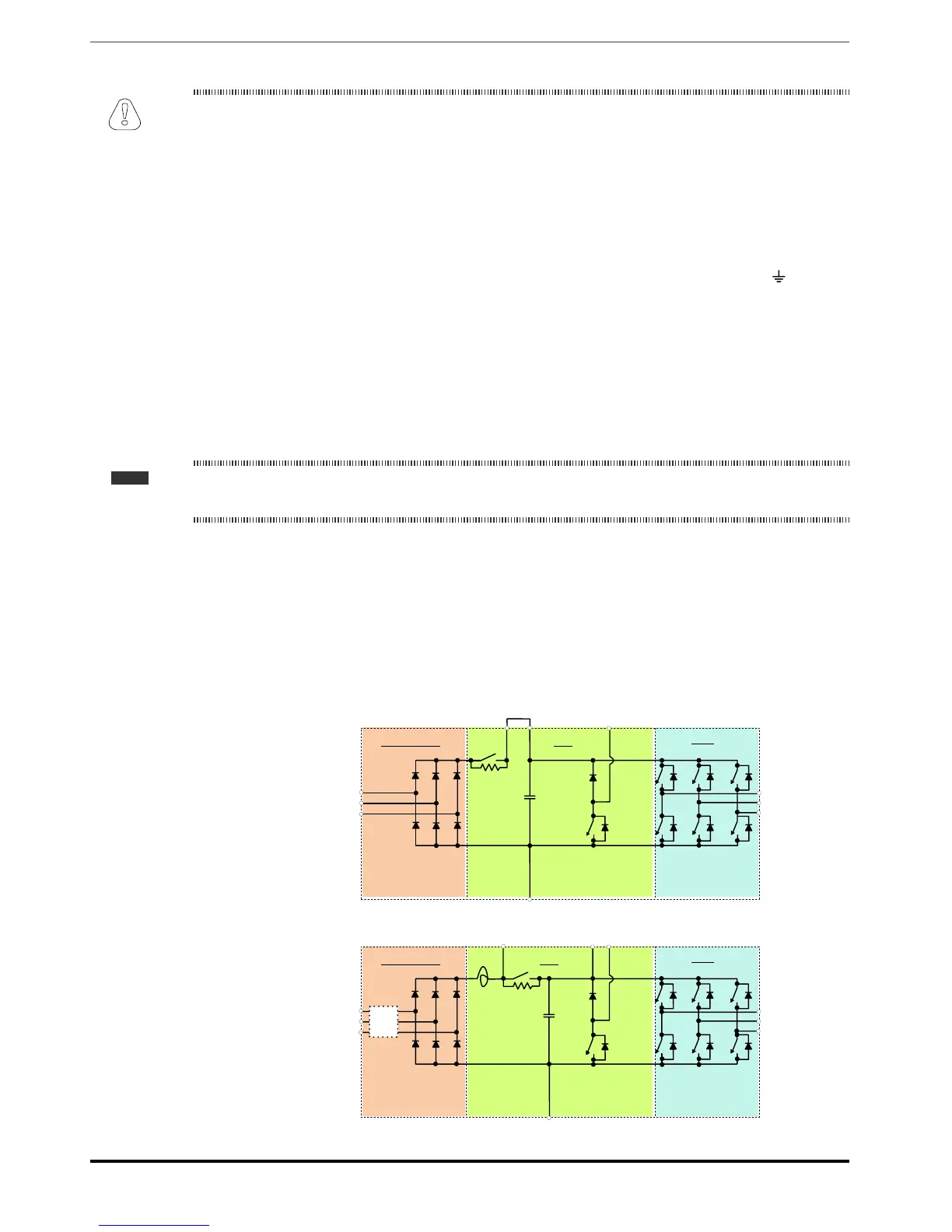

7.1.4 Block diagram of power section

This type is equipped with an EMI input lter (only on ≥ 4300 sizes), an AC/DC converter, a system for pre-loading DC

capacitors, a DC/AC converter, a power supply unit and an integrated braking unit ((only on ADV1..-…-KBX models).

A specic external resistor must be connected to perform the braking function.

The connection of the external braking resistor depends on the drive size:

• for 4 to 22 kW drives, connect the resistor between terminals C (or C1) and BR

• for 30 to 90 kW drives, connect the resistor between terminals BR1 and BR2.

L1

L2

L3

Emi filter & converter

DC link

Inverter

Rprc

EMI

filter

L1

L2

L3

Emi filter & converter

DC link

Inverter

Rprc

C1 C BR

D

D

C BR1 BR2

U

V

W

U

V

W

1040 - 3220

≥ 4300

Ldc

Attention

Loading...

Loading...