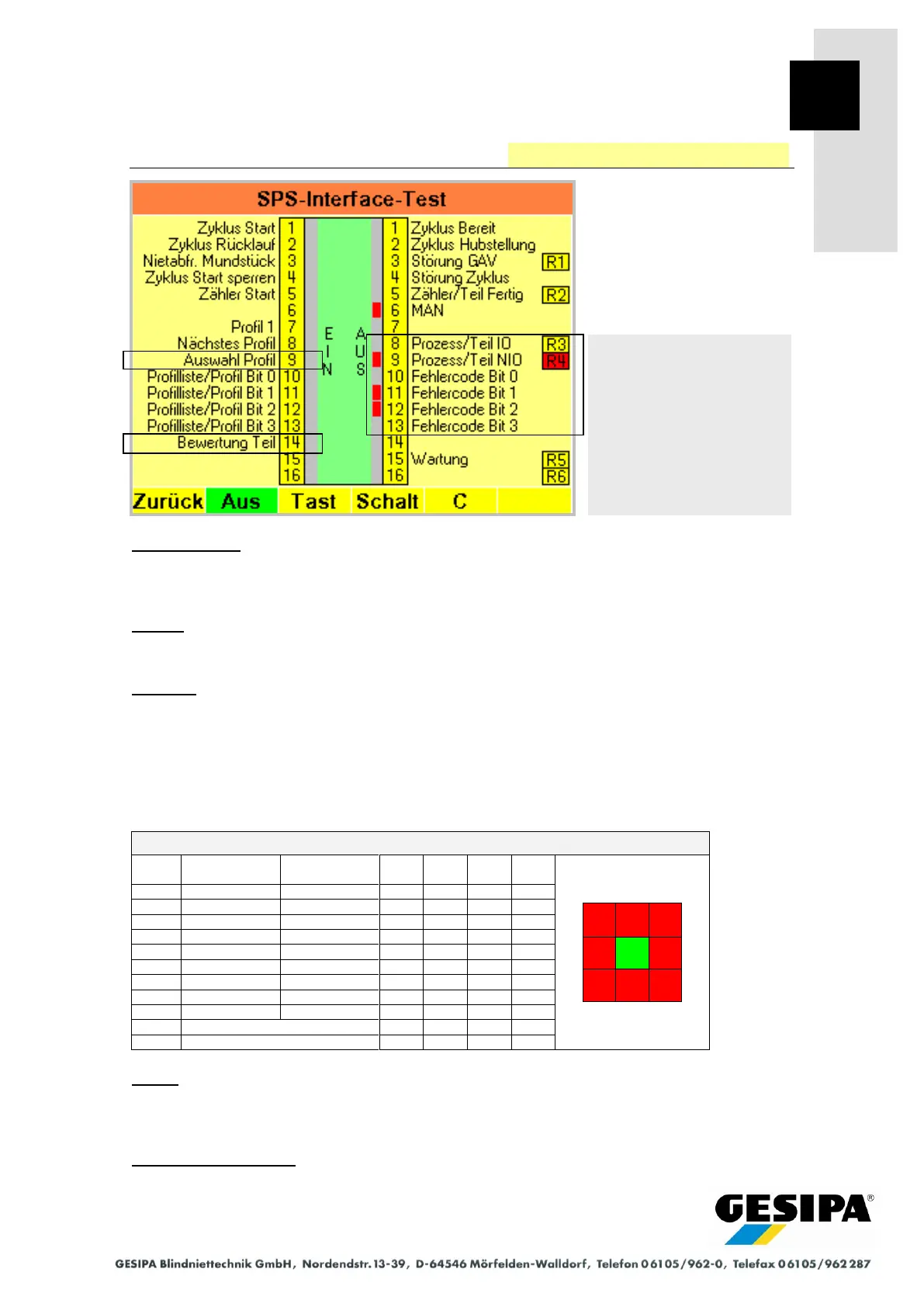

PLC Interface

28.8 Process Evaluation

Preconditions:

● PLC interface connected to GAV.

● Process monitoring active (see Section 11 "Process Monitoring").

Inputs:

Input 9 "Profile Selection" and input 14 "Part Evaluation" must be 0 (0 V).

Outputs:

● Output 8 "Process IO" evaluation, output 9 "Process NOK" evaluation and the outputs 10 to

13 "Error Code" are set to 0 (0 V) at the beginning of each process.

● At the end of each process the evaluation "Process OK" is output at output 8 or "Process

NOK" at output 9 with 1 (24 V). The error code for "Process NOK" evaluation is output at

outputs 10 to 13.

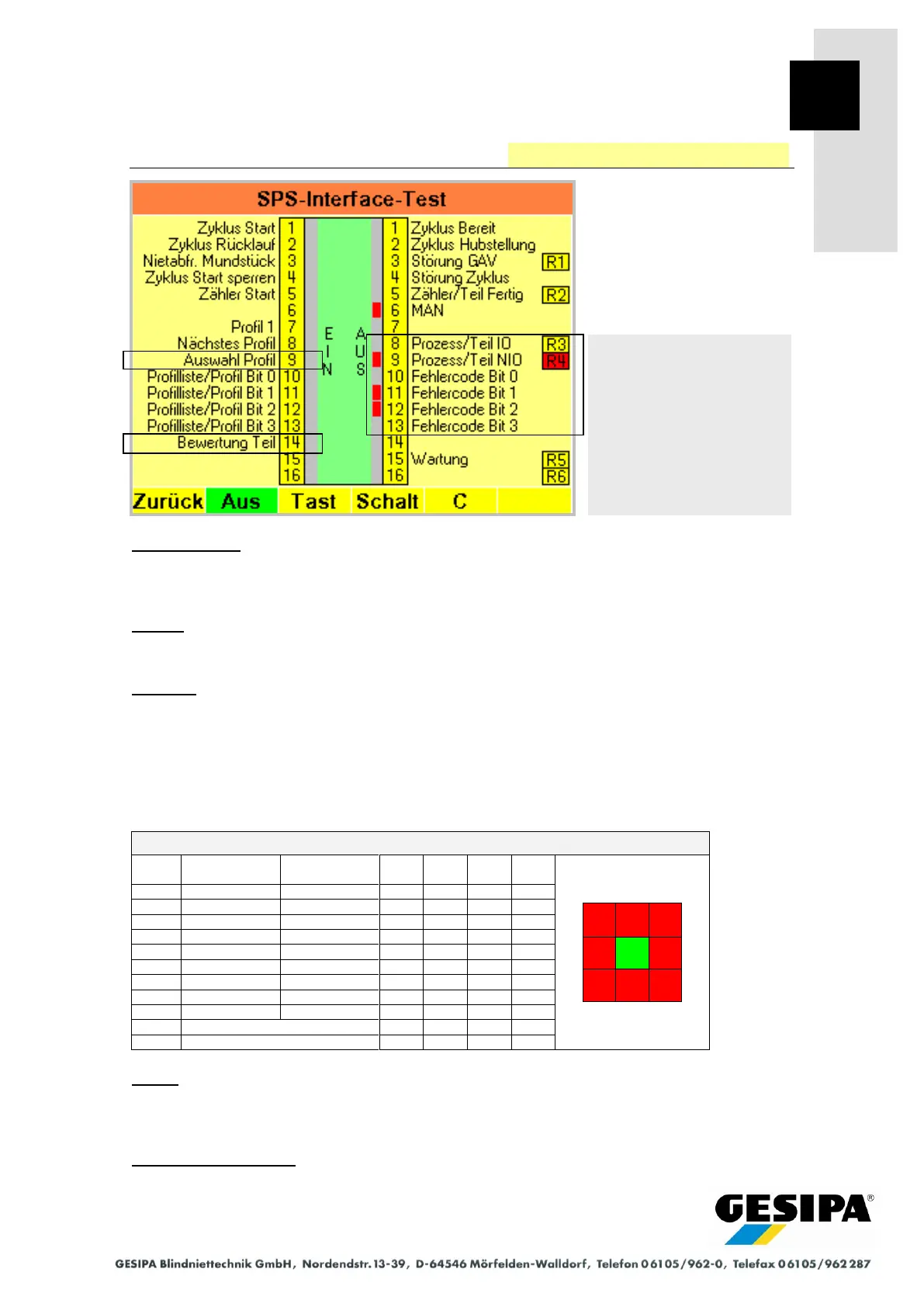

Error code (outputs 10 to 13)

Relay:

Relay R3 is switched when output 8 "Part OK" evaluation is 1 (24 V).

Relay R4 is switched when output 9 "Part NOK" evaluation is 1 (24 V).

Example (see screen):

"Process NOK" evaluation, error code 6 "Break-off force and break-off displacement undershot".

Navigation:

AUTO

►MAN

► Menu

► GAV settings

► PLC interface test

Loading...

Loading...