29 Displacement sensor (WS1) teach-in

Displacement sensor (WS1) teach-in

29.0 Defining measuring range at displacement sensor

Note on teach-in procedure:

The teach-in procedure for the displacement sensor serves the

purpose of setting a precisely predefined measuring range at the

large pressure booster of the GAV 8000. The procedure precisely

sets the start and end points (= measuring range). Teach-in of

the measuring range is important in order to avoid faults and mal-

functions as the control software of the GAV 8000 evaluates the

measured values of the displacement sensor and refers them to

predefined, programmed values.

Quick guide:

- The measuring range must be taught in at the displacement

sensor WS1.

- The displacement sensor WS2 on the large pressure booster

and displacement sensor WS3 on the small pressure booster

are not taught in. They remain set to the factory setting. For

safety reasons, the calibration must be checked and reset to

the factory setting if necessary (see "Resetting to factory

setting").

Adjustment:

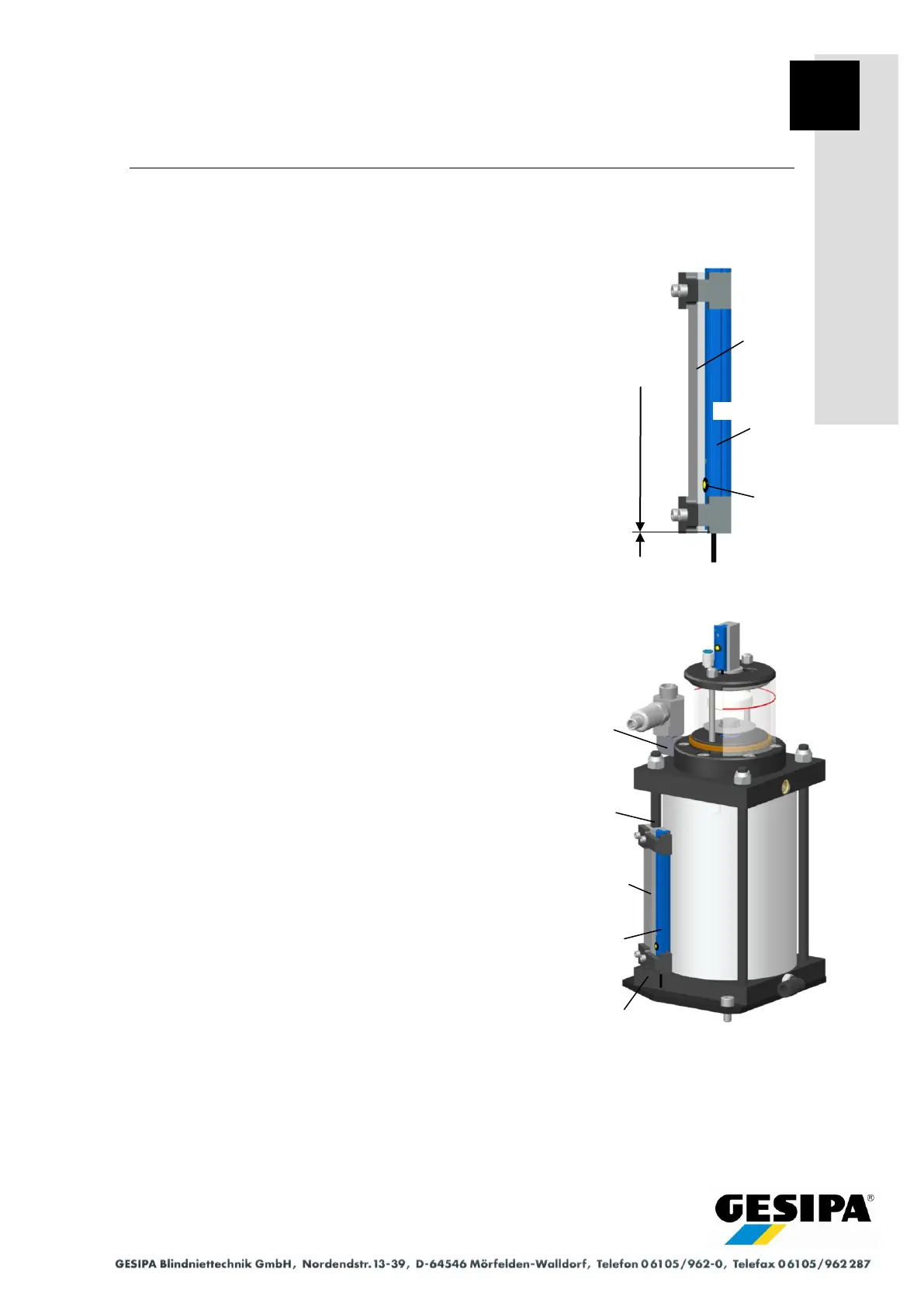

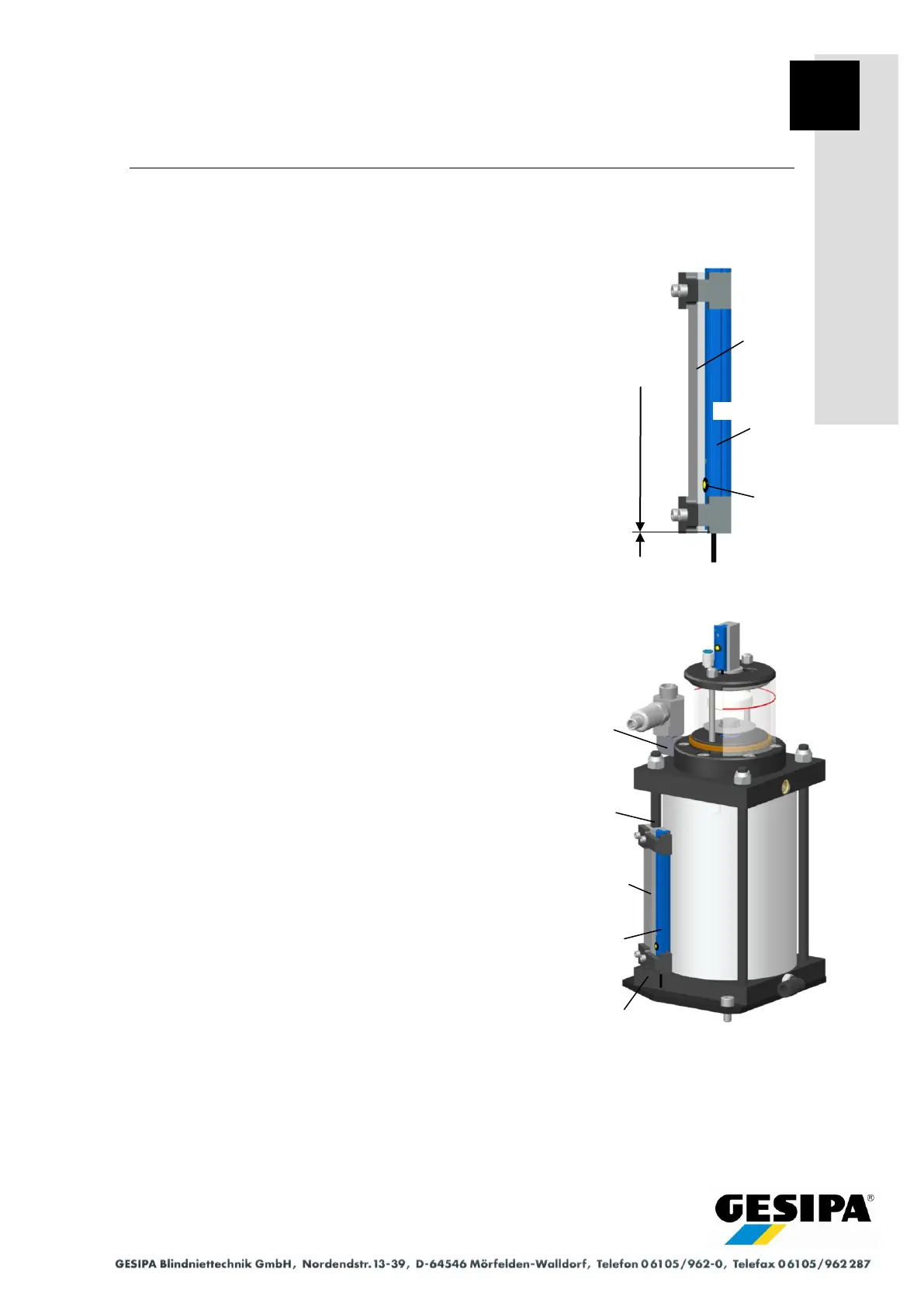

- The displacement sensor (WS1) teach-in proce-

dure must be carried out at the large pressure

booster in the GAV supply unit.

- Assemble the displacement sensor with the cable

end facing downward flush with the bottom face of

the sensor holder outside the supply unit and se-

cure.

- Plug the displacement sensor into the socket of the

wiring harness at the supply unit. Switch on supply

unit, operating voltage is now supplied to the dis-

placement sensor.

- Select "Calibration WS1, large pressure booster

calibration" on the display (see Section 9 "GAV

Settings - Large Pressure Booster").

- Press the sensor holder with the cable end facing

downward onto the right-hand tie rod, as viewed

from the hydraulic connection.

Install displacement sensor

flush with sensor holder

Loading...

Loading...