11.1 Functional Principle

Process Monitoring

11.1 Functional Principle

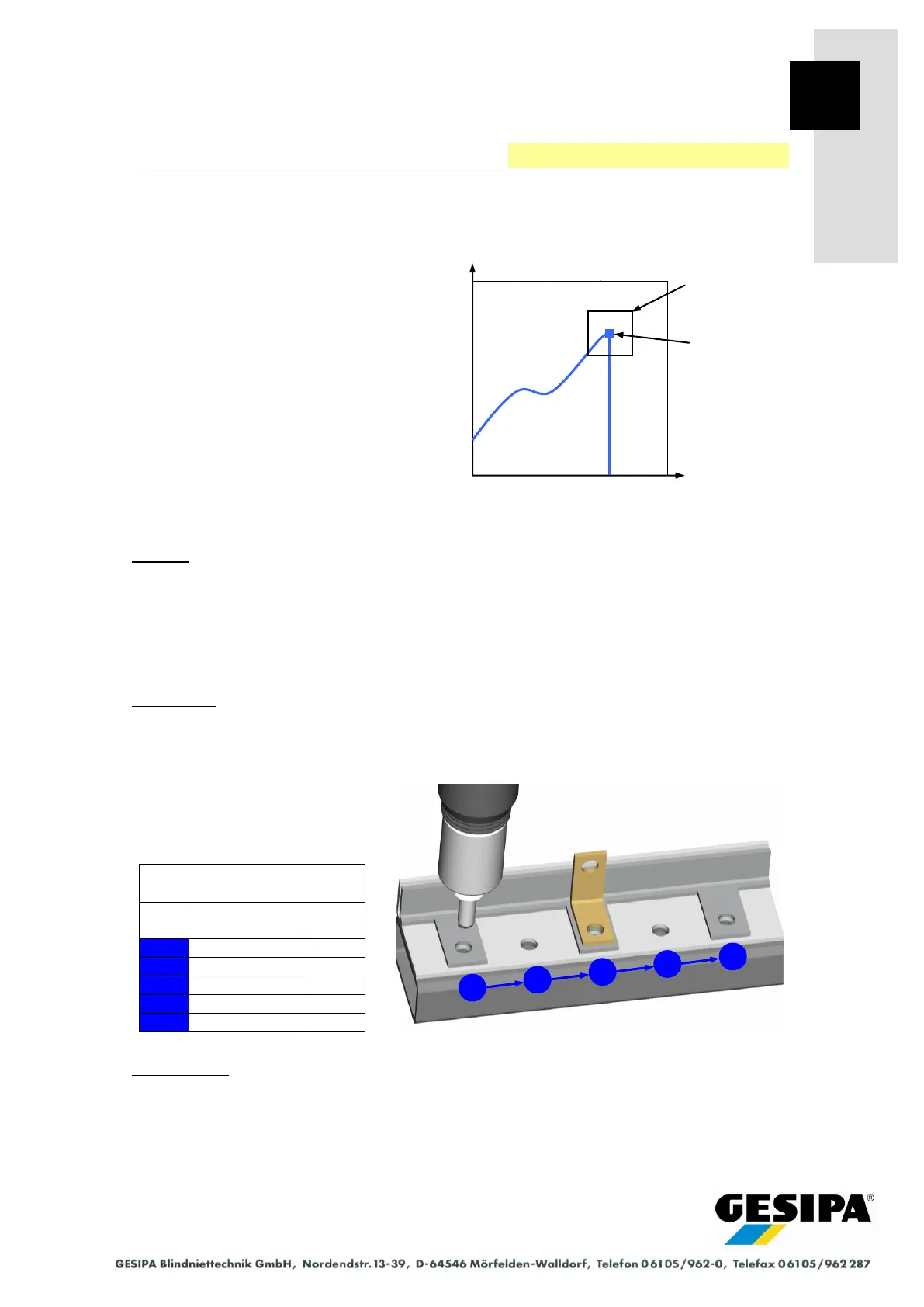

The setting process in GAV is monitored by recording the pulling displacement and pulling force

during blind rivet processing and subsequently assessing the break-off point (break-off dis-

placement and break-off force). The po-

sition of the break-off point largely de-

pends on the type of blind rivet used, the

thickness of the material to be joined and

the hole diameter in the material.

To assess the break-off point, the limits

for break-off displacement and break-off

force are defined in a window system.

The limits are visualised in an evaluation

window.

Evaluations are shown on the graphic

display immediately after each setting

process and output via the PLC inter-

face.

Profiles

The evaluation parameters defined for individual blind riveting points are stored in profiles. A

maximum of 9999 different profiles can be created. Profiles can be changed, a copy of the last

profile with the new index is created, a maximum of 9999 changes per profile are possible.

It is necessary to use profile lists for component-related group evaluations.

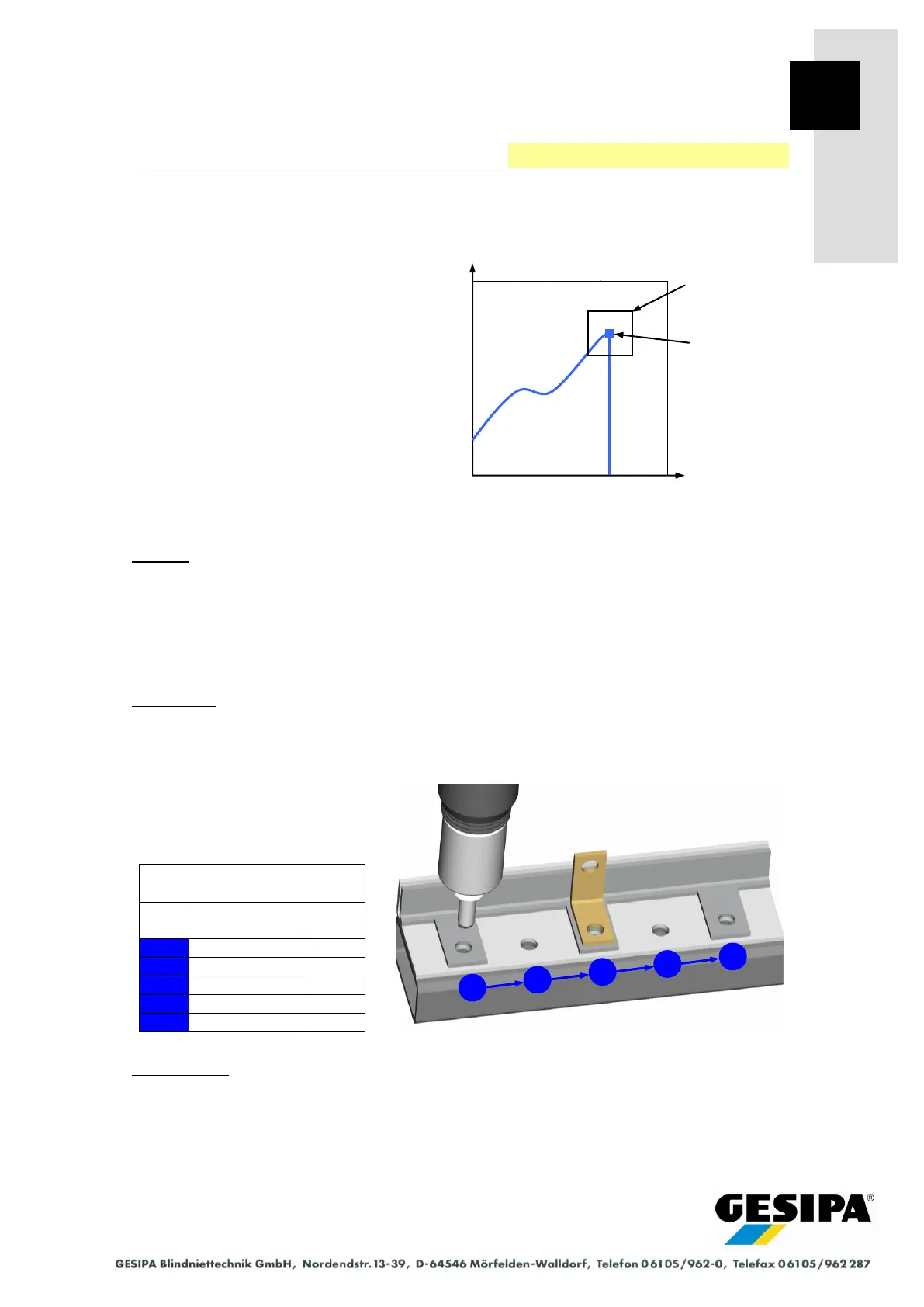

Profile lists

Profile lists are created for applications with several blind riveting points that need to be as-

sessed in different ways. A profile list can assess each blind riveting point with the profile creat-

ed for this point. Profiles are automatically called up one after the other from the profile lists or

activated directly by the PLC inter-

face. A maximum of 9999 profile

lists each with a maximum of 9999

profiles can be created.

Process data

The position of the break-off point and the evaluation of the setting processes are saved with a

time stamp in the process data file. The process data file contains the last 1,000,000 processes.

The oldest data are overwritten to accommodate the latest data. Evaluation of the process data

is described in Section 12 "Process Data".

Example:

Profile list "Test part"

Loading...

Loading...