34

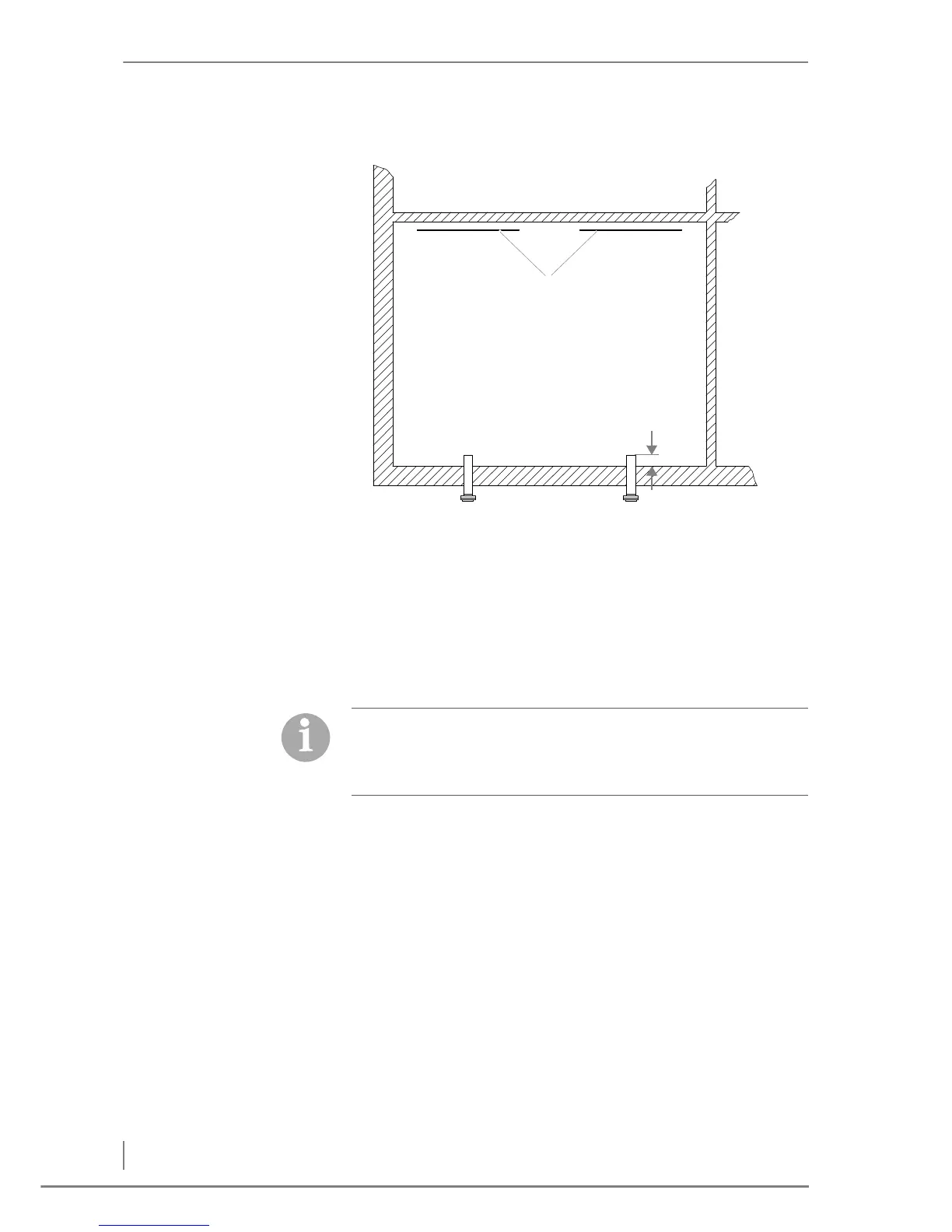

• Injection and extraction nozzles to be used alternately for filling:

1 Pellet anti-shatter protective mat

A) approx. 10 cm

If the injection and extraction nozzles are used alternately for filling

from the long side of the bunker, the existing space can be better

utilised.

A protective mat must then be installed for both nozzles.

P

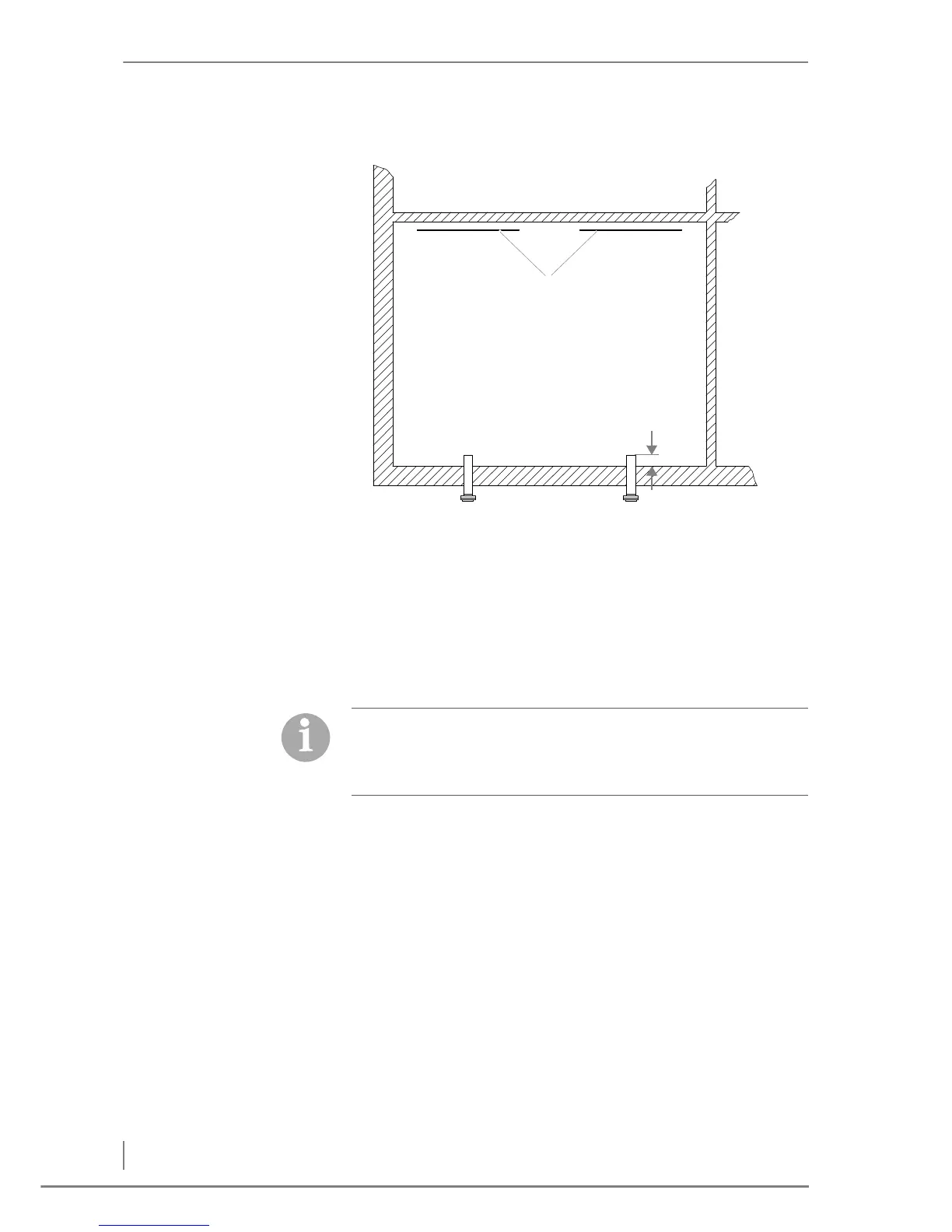

ASSAGE THROUGH THE WALL The passage through the wall normally has to be made in the wall

between the boiler room and the pellet bunker. Its position should

be as central as possible.

The passage should be 25 cm wide and 28 cm high.

When installed, the lowest point of the sloping floor panels should be

at least 5.5 cm above the level of the floor in the boiler room.

Figure 4/7 - Injection and extraction nozzles, variant 3

Position the pipes as high as possible in the bunker so as to be able

to fill to the maximum. Minimum clearance to ceiling approx. 20 cm,

so that the pellets don't hit the ceiling. Plaster ceilings will need a

protective panel.

Loading...

Loading...