30 – 602 HEIDENHAIN Service Manual iTNC 530

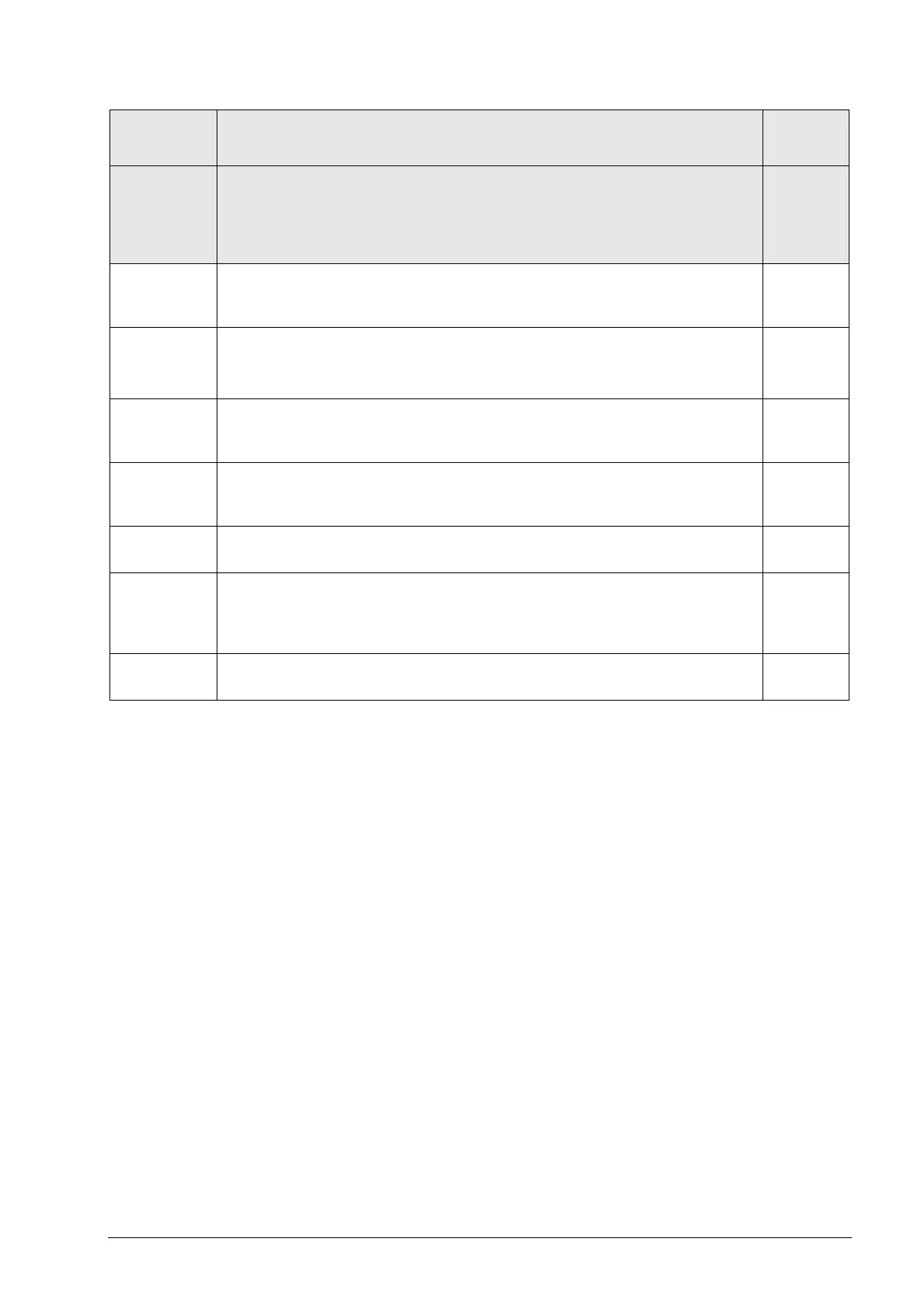

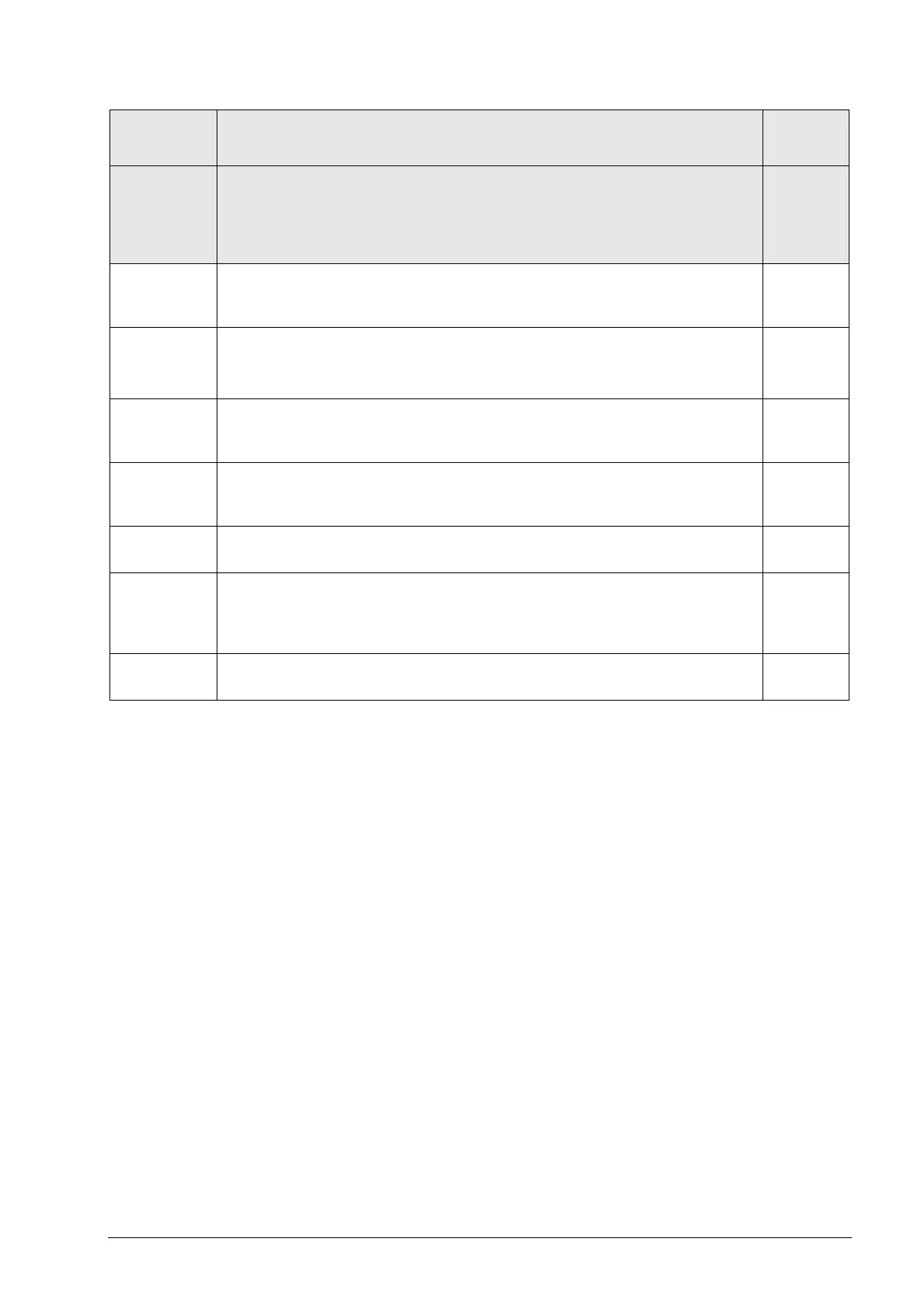

MP2614.x Only CC 424(B): Distance after the reversal point from which a reduction of the current

from MP2610.x is to go into effect.

Input: 0.000 to 1.000 [mm] or [°]

0: Friction compensation same as CC 424

0.1: Typical input value

PLC

RUN

MP2620.x Friction compensation

Input: 0 to 100.000 [A]

0: No friction compensation (or axis is analog)

PLC

RUN

MP2630.x Holding current

Input: -100.000 to +100.000 [A]

PLC

RUN

340 490-03

MP2640.x As of CC424(B): Torsion compensation between position encoder and speed encoder

0.001 to 30.000 [µm/A]

0: Not active

340 490-03

MP2900.x Tensioning torque between master and slave for master-slave torque control

(entry for the slave axis)

Input: -100.00 to +100.00 [Nm]

PLC

MP2910.x P factor of the torque controller for master-slave torque control (entry for the slave axis)

Input: 0.00 to 999.99 [1/(Nm ⋅ min)]

PLC

MP2920.x Factor for variable torque distribution of the master-slave torque control

(entry for the slave axis)

Input: 0.000 to 100.000

1: Master and slave axes have identical motors

PLC

MP2930.x Speed compensation ratio for master-slave torque control (entry for the slave axis)

Input: –100.00 to +100.00 [%]

PLC

MP Function and input SW version

and

behavior

Loading...

Loading...