340 ISO Programming

4.26 Milling Cycles

Parameters—Milling

A Sequence for “Milling”: A=0 (default=0)

NF Position mark—reference from which the cycle reads the hole

positions [1 to 127].

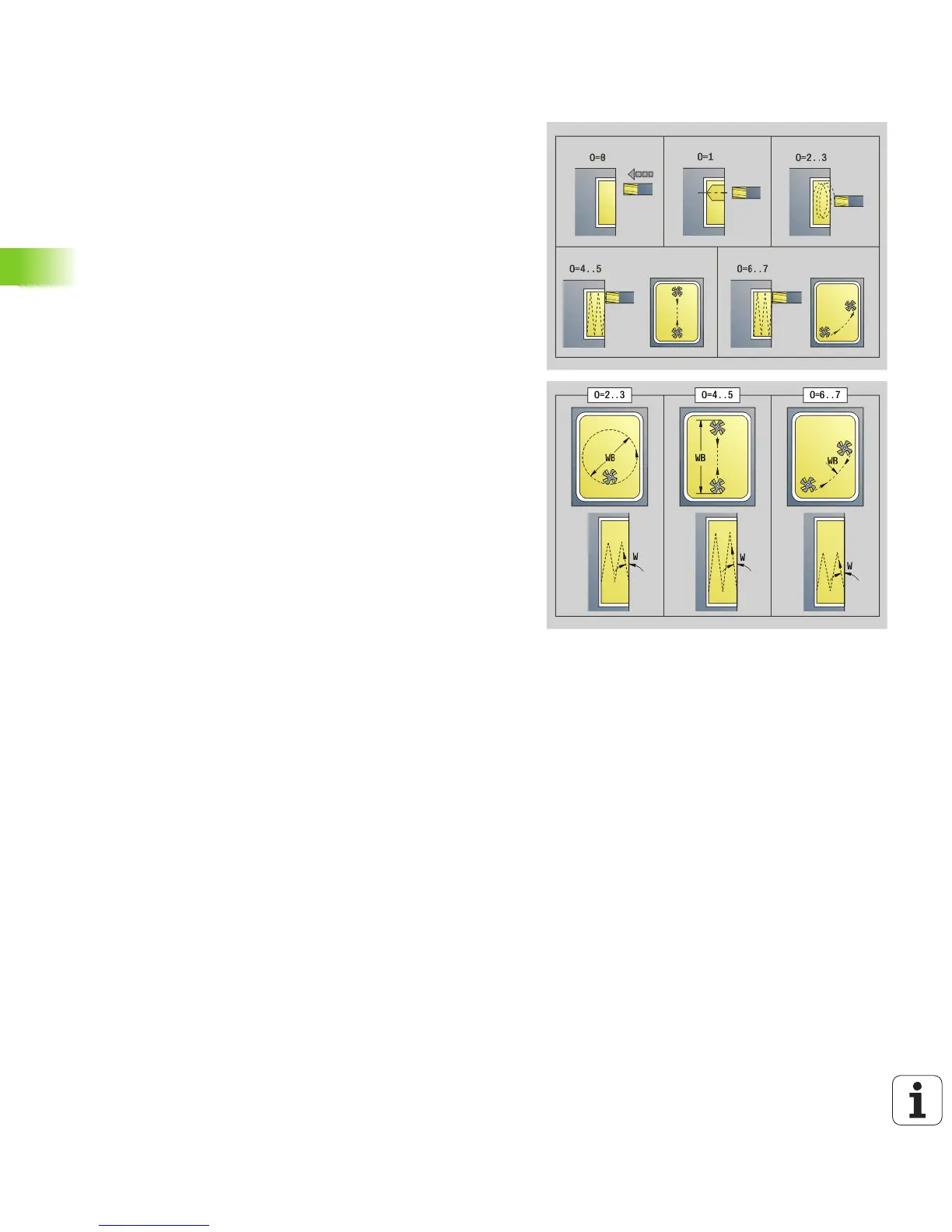

O Plunging behavior (default: 0)

O=0 (vertical plunge): The cycle moves the tool to the

starting point; the tool plunges at the feed rate for infeed and

mills the pocket.

O=1 (plunge at pre-drilled position):

If “NF” is programmed: The cycle positions the milling

cutter above the first pre-drilled hole; the tool plunges and

mills the first section. If applicable, the cycle positions the

tool to the next pre-drilled hole and machines the next

section, etc.

If “NF” is not programmed: The tool plunges at the current

position and mills the section. If applicable, position the tool

to the next pre-drilled hole and mill the next section, etc.

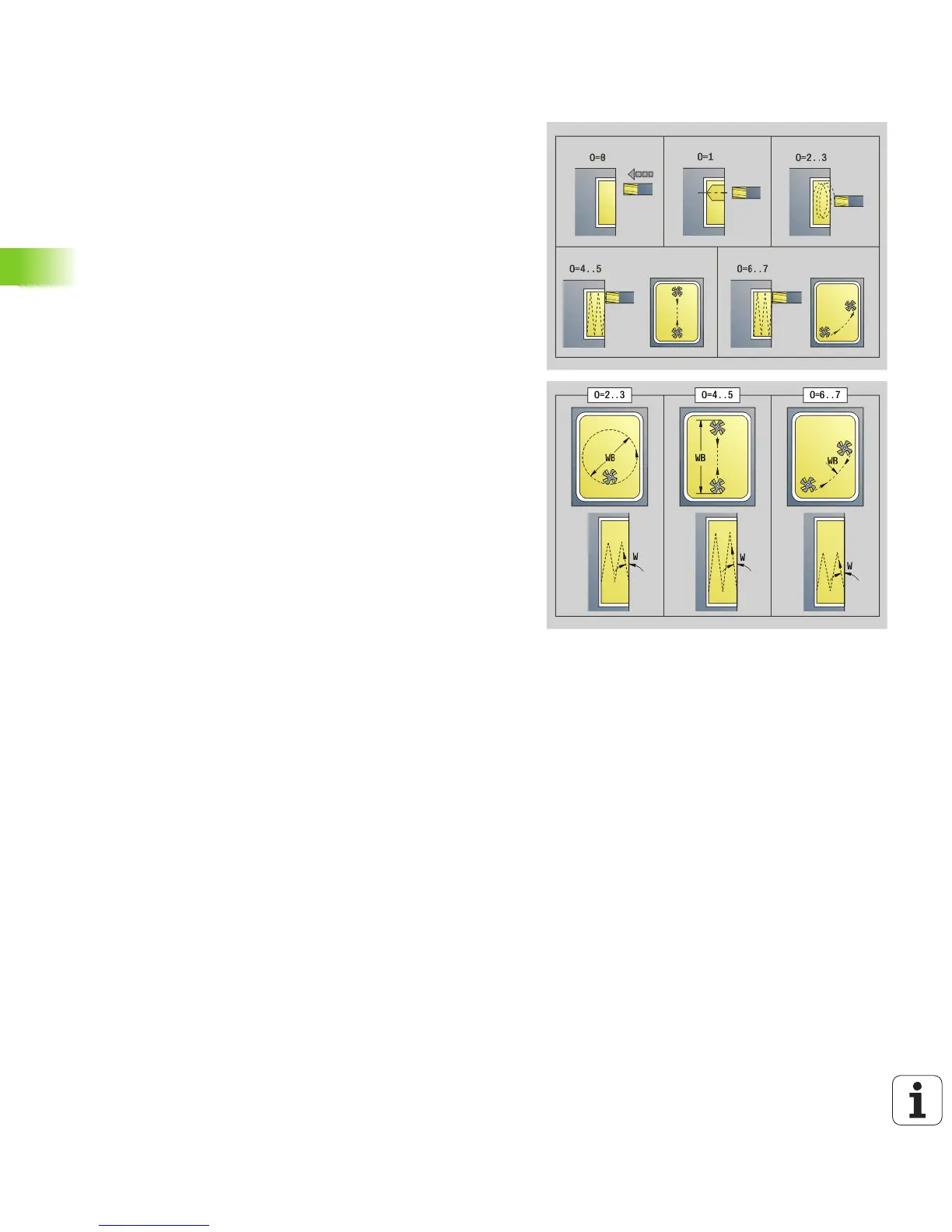

O=2, 3 (helical plunge): The tool plunges at the angle “W”

and mills full circles with the diameter “WB.” As soon as it

reaches the milling depth “P,” the cycle switches to face

milling.

O=2—manually: The cycle plunges at the current position

and machines the section that can be reached from this

position.

O=3—automatically: The cycle calculates the plunging

position, plunges and machines this section. The plunging

motion ends at the starting point of the first milling path, if

possible. If the pocket consists of multiple sections, the

cycle successively machines all the sections.

O=4, 5 (reciprocating linear plunge): The tool plunges at the

angle “W” and mills a linear path of the length “WB.” You can

define the orientation angle in “WE.” The cycle then mills

along this path in the reverse direction. As soon as it reaches

the milling depth “P,” the cycle switches to face milling.

O=4—manually: The cycle plunges at the current position

and machines the section that can be reached from this

position.

O=5—automatically: The cycle calculates the plunging

position, plunges and machines this section. The plunging

motion ends at the starting point of the first milling path, if

possible. If the pocket consists of multiple sections, the

cycle successively machines all the sections. The plunging

position is determined from the type of figure and from “Q”

as follows:

Loading...

Loading...