14

────────────────────────────────────────────────────

1.3 Measurements and Working Systems

────────────────────────────────────────────────────

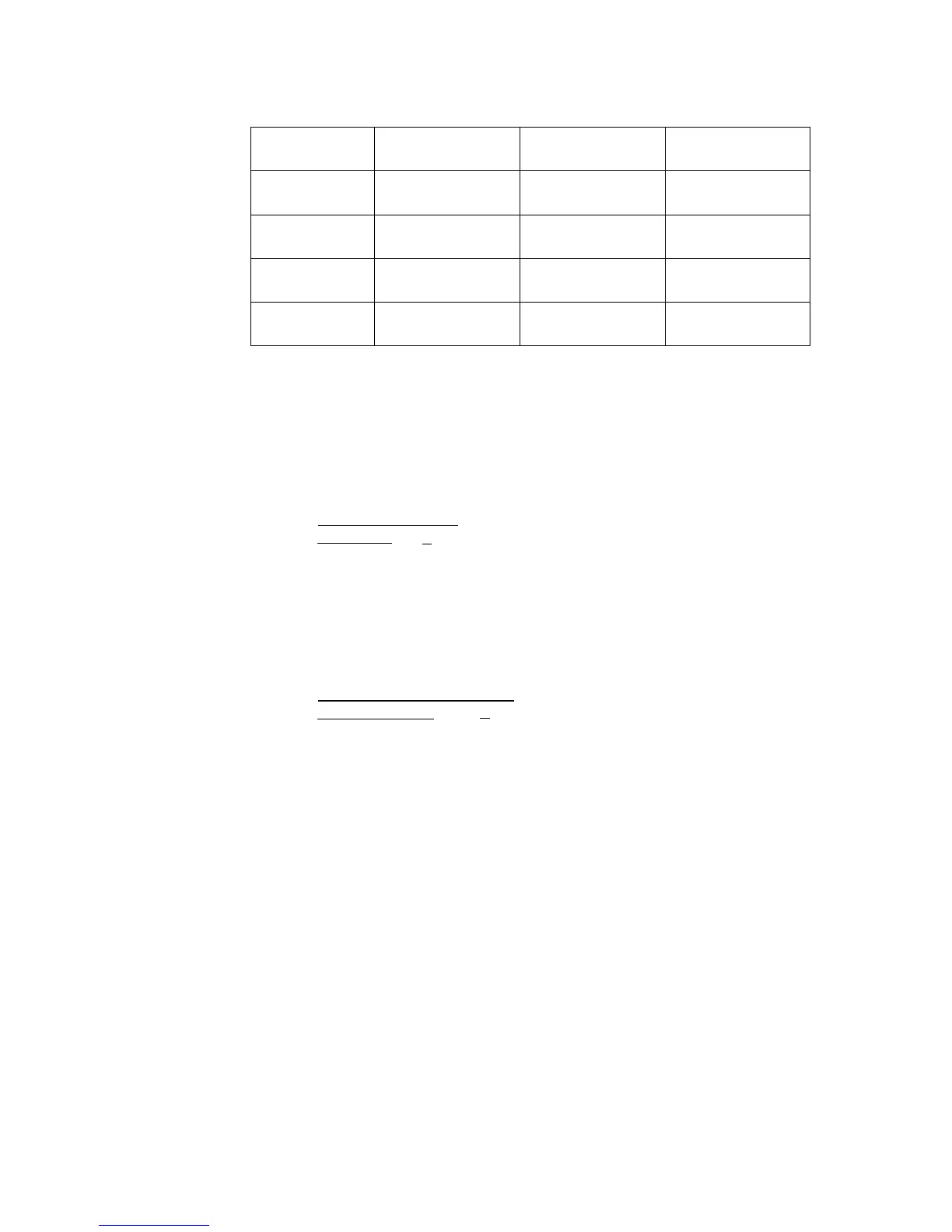

Diameter [mm]

Annealed copper

wire

Tin-plated annealed

copper wire

Hard drawn coppe

(1) Properties of metal and alloy conductive materials

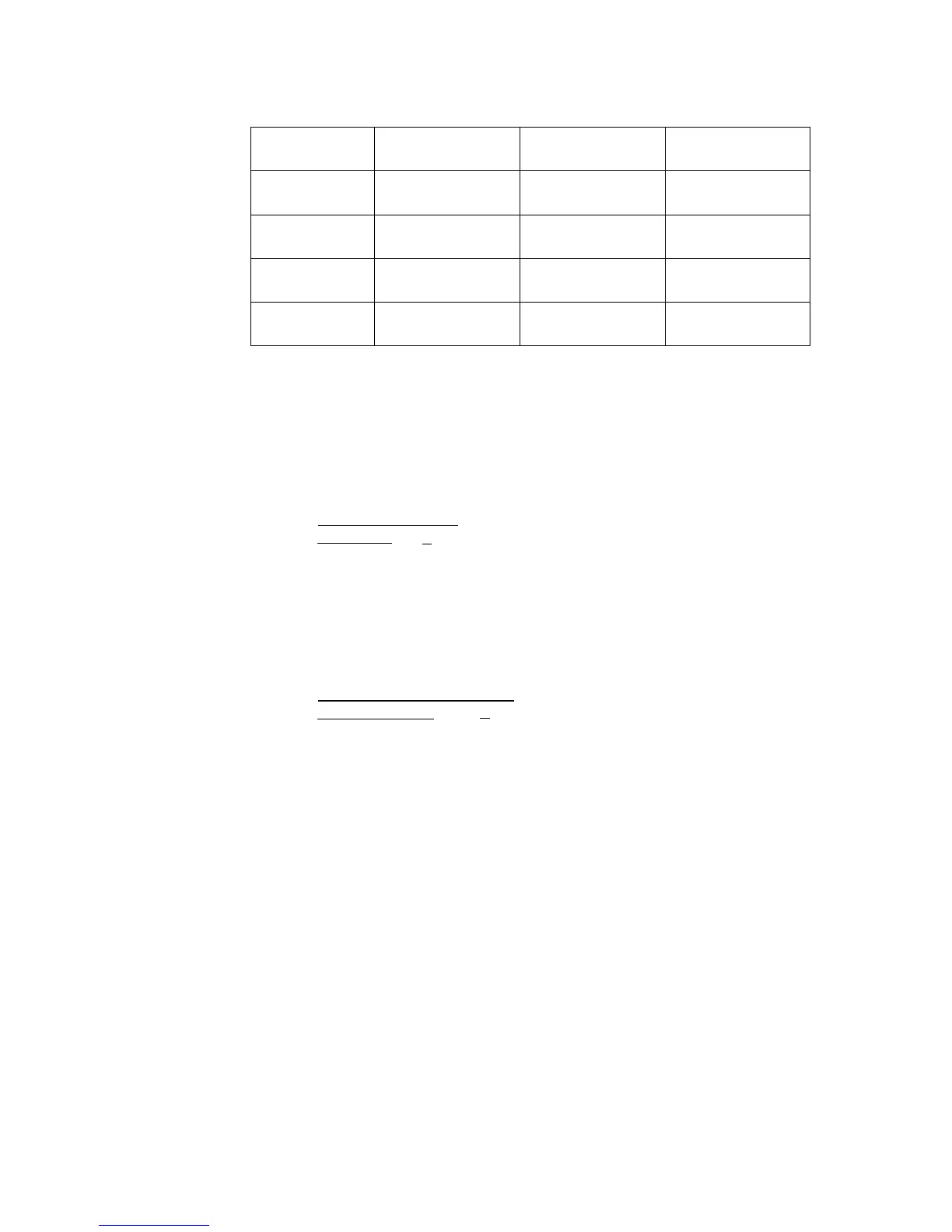

(2) Conductivity of copper wire

The temperature coefficient changes in relation to temperature and

conductivity. Assume the temperature coefficient is α

20

at 20℃ and that the

temperature coefficient is α

Ct

at t (℃) with a conductivity of C. Then Ct at

around room temperature is represented as follows:

The temperature coefficient of international standard annealed copper is 3930

ppm at 20℃. For tin-plated annealed copper wire (not less than 0.10 but

below 0.26 in diameter), the temperature coefficient α

20

at 20℃ can be

calculated using the following formula:

Loading...

Loading...