34

ELECTRICAL AND CONTROL SETTINGS

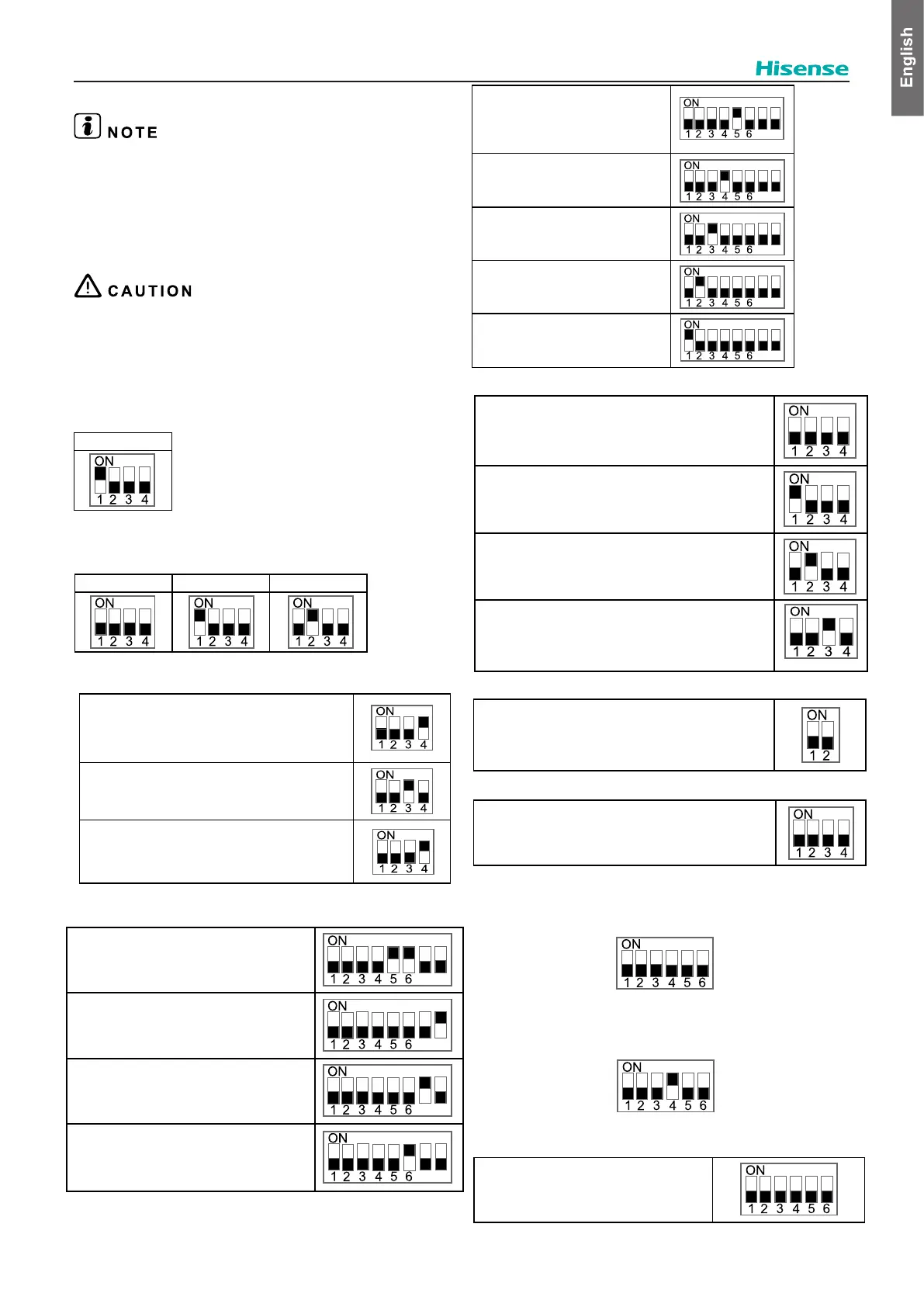

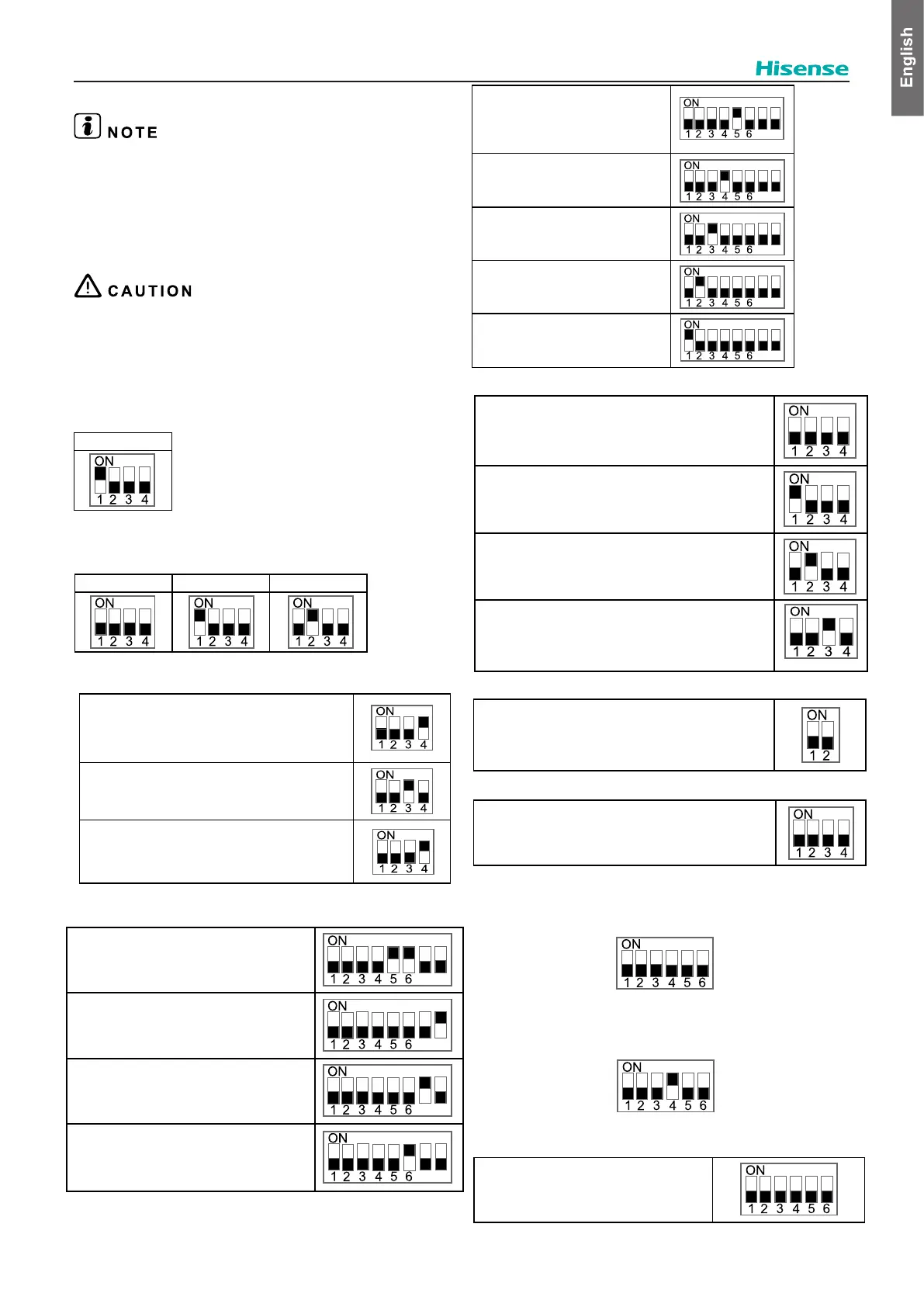

10.5 SETTING OF DIP SWITCHES ON PCB1

selection.

malfunction might occur if changed.

then set the position of dip switches. If the switches are set without

(1) DSW1: Unit model setting

No setting is required.

(2) DSW2: Unit capacity setting

No setting is required.

044(2.0 HP) 060(2.5 HP) 080(3.0 HP)

(3) DSW3: Additional setting

(4) DSW4: Additional setting

6HWWLQJEHIRUHVKLSPHQW

$QWLIUHH]LQJVHWWLQJV

21:KROHZDWHUF\FOHGRHVDQWLIUHH]LQJ

2))2QO\SULPDU\F\FOHGRHVDQWLIUHH]LQJ

21&DQFHODODUP:DWHUSUHVVXUHDEQRUPDOLW\

Setting before shipment

7 8

Water pump forced ON

7 8

Auxiliary electric heater

forced OFF

7 8

ON: Anti-freezing enabled

OFF: Anti-freezing disabled

7

8

Manual emergency setting

ON: Manual emergency enabled

OFF: Manual emergency disabled

7 8

DHW electric heater allowance setting

ON: DHW electric heater cancel forced OFF

OFF: DHW electric heater forced OFF

7

8

DHW 3-way valve forced ON

7 8

Start air purge

7 8

Water pump mode when Thermo OFF

ON: Operate periodically

OFF: Operate constantly

7

8

(5) DSW5: Additional setting

(6) DSW6: Fuse reset

(7) DSW7: Not used

(8) DSW8: Refrigeration system No. setting

Setting is required.

Use binary encoding method. Before shipment are all OFF.

Setting before shipment

ON: WP3 operates in space cooling mode.

ON: Cancel 75/78 alarm (Water pump abnormalities)

Setting before shipment

Setting before shipment

(9) DSW9: Indoor unit No. setting.

No setting is required.

Max No.63 are available to set when all the equipment are

connected to corresponding Central Control System.

Ex: Set refrigeration system No. as 8.

Setting before shipment

ON: Cancel Alarm of Thermistor Tow2

Integra

Loading...

Loading...