133

fi g. 9.12

9 - T, S M

Inspections and Maintenance

Proper maintenance and service will warrant safe and trouble-free operation of an F2 Series

motorized unit and its accessories. In order to ensure operational safety and avoid failures,

the owner and/or user must make sure that all the scheduled inspection and maintenance

operations have been eff ectively and timely carried out according to the inspection and

maintenance schedules for F2 Series motorized units and their accessories.

Blank copies of the daily inspection checklist must be available on job sites at all times to

be fi lled out when daily and weekly inspection operations are carried out. Maintenance and

inspection logs must be kept on record for warranty and safety purposes.

Copies of all maintenance and inspection checklists can be obtained by contacting the

distributor/service center or downloaded directly from the Hydro Mobile website at www.

hydro-mobile.com.

A proper and timely greasing of the gears and the racks is critical to guarantee performance

and longevity of the Hydro Mobile F2 Series mast climber system. It is important to

understand that not all open gear greases and lubricants off er equal levels of quality and

performance. Consequently, only open gear grease recommended by Hydro Mobile must

be used on Hydro Mobile equipment.

Application frequency must be based on the installation and the cumulative runtime use

of the equipment. However, the gears and racks must typically be greased after every

8 to 10 hours of operation (with unit traveling up and down the mast).

Gears and racks on a typical mast climber with a duty cycle of 25% will require to be

greased on a weekly basis.

8 hrs/day * 5 days * 25% duty cycle = 10 hrs

Higher duty cycle operation will require greasing to be more frequent. For example, use

of the F2 Series mast climber in a transport platform application in 100% duty cycle will

increase greasing requirements to up to once a day.

The greasing of the racks and gears must be done with care, using an open gear lubricant

recommended by Hydro Mobile.

At the end of the working shift, grease must be applied to the gears and to the racks

from the top of the mast down. Grease must be allowed to stand for 2-3 hours before

the motorized unit is used again (travel up and down the mast).

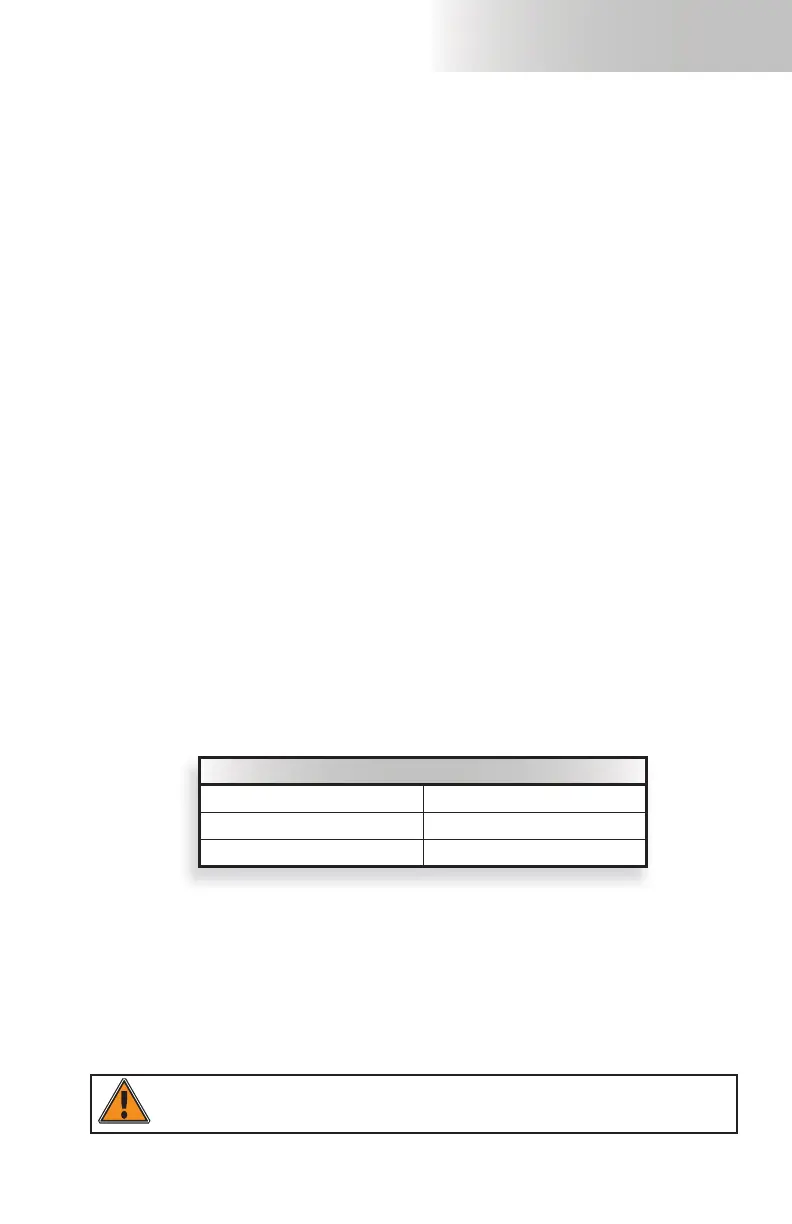

Greasing of gears and racks

Recommended open gear lubricants

Manufacturer Part number

Prolab OG-700

Petron Corporation Gear Shield NC

WARNING

Grease must never be applied to any part of the overspeed safety device.

Old grease expelled out of the gear meshing must be cleaned off on a regular basis.

The rack must be visually inspected at the end of each working shift and grease must be

applied if needed.

Any grease accumulation found on

any part of the overspeed safety device must be

reported immediately and the motorized unit must immediately be put out of service

until the overspeed safety device has been inspected and cleaned by a qualifi ed technician

or an appropriately qualifi ed person. For the defi nition of a qualifi ed person, refer to p. 7

of the Performance and Safety Rules section.

Loading...

Loading...