67

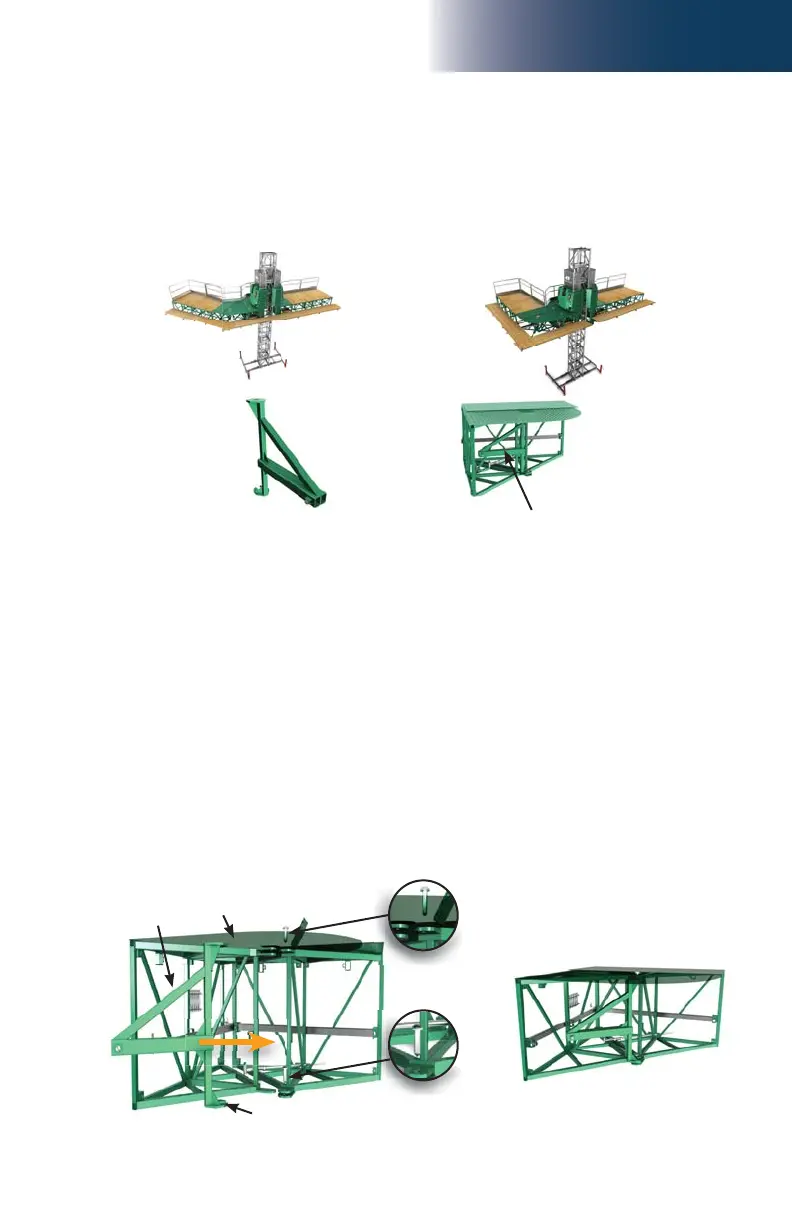

fi g. 3.63

fi g. 3.64

fi g. 3.65

fi g. 3.66

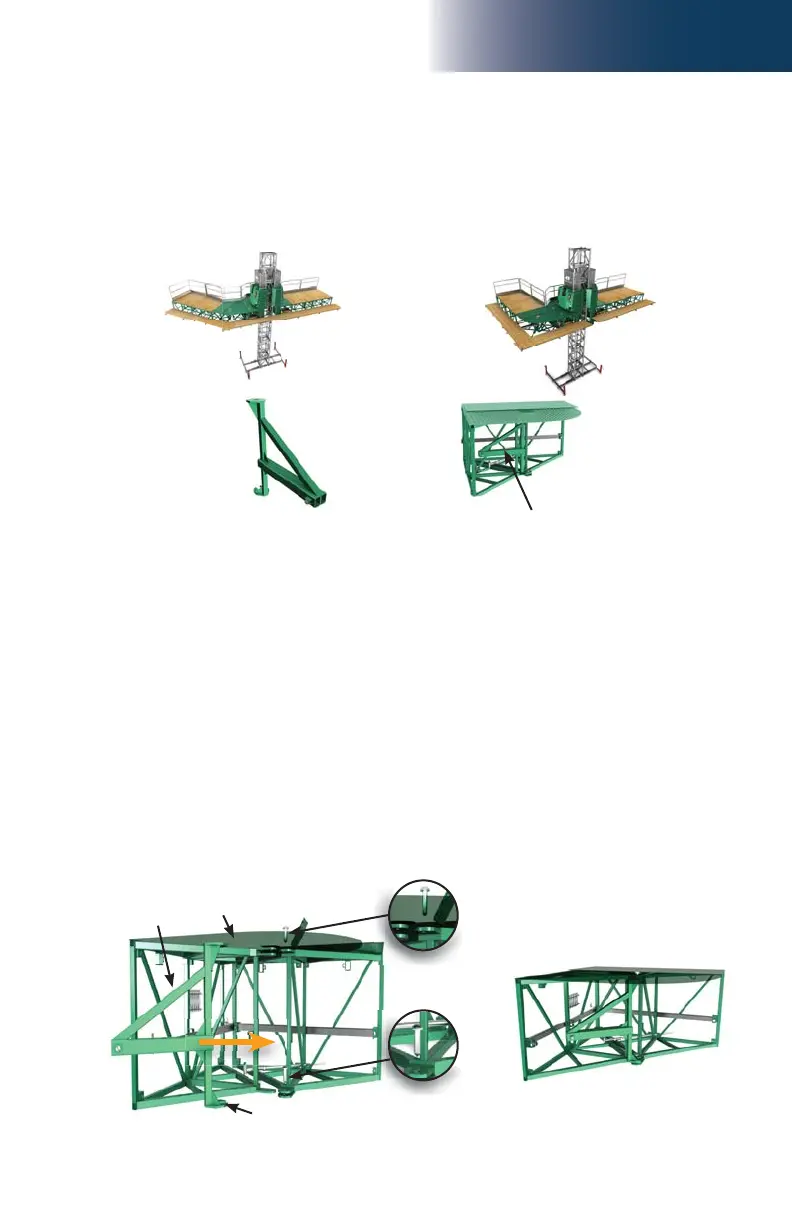

fi g. 3.67

fi g. 3.68

fi g. 3.69

fi g. 3.70

3 - B

Outrigger

support

assembly

Swivel

bridge

Top pivot pin

Bottom pivot pin

Bottom

(forked) plate

Bridges

Swivel Bridge Outrigger Support Assembly

The outrigger support assembly is designed to be used as a plank support structure in

swivel bridge back confi gurations (0 to 45° and 90°).

0 to 45° confi gurations 90° confi guration

Outrigger support

assembly

Outrigger support assembly

stored inside swivel bridge

(transport position)

(optional)

Installation

1- Make sure that the end of the swivel bridge that is not bolted to the main frame (pivoting end,

fi g. 3.53, p. 65) is supported so the two halves of the swivel bridge remain together.

2- Remove the lock bolt from the top pivot pin (fi g. 3.68). It is not necessary to remove

the lock bolt from the bottom pivot pin.

3- Lift out the top pivot pin until it clears the top part of the pivot structure and it is possible

to align the hole in the top plate of the outrigger support assembly. It is not necessary

to remove the pivot pin completely. Lift out the bottom pivot pin (fi g. 3.69) until it is

possible to insert the bottom plate around the pivot pin of the outrigger support assembly.

4- Slide in the bottom plate of the outrigger support assembly around the bottom pivot pin

and align the hole of the top plate with the top pivot pin. Insert the pivot pin.

5- Tighten the top lock bolt to secure the top pivot pin.

Loading...

Loading...