16

1

2

1

2

2

fi g. 1.21

fi g. 1.24

fi g. 1.22

fi g. 1.23

1 - M U

Positioning the Motorized Unit

Bearing surface

Before installing the motorized unit, make sure the bearing surface under it is level, clear of debris

and has the proper bearing capacity. Appropriate cribbing must be placed under the base to

distribute the load. It is important to make sure that the bearing surface is stable and has not been

subject to any type of erosion or deterioration caused by weather conditions (snow, rain, etc.).

General Concept

Recommended cribbing for most bearing surfaces

The plywood and lumber used as cribbing must be secured together to prevent slipping. Using

screws instead of nails for securing will prolong the service life of lumber and plywood used

as cribbing.

Values shown in the above table are for reference only. Any cribbing that

covers the mandatory cribbing area (as shown in fi g. 1.22) can be used.

The type of cribbing chosen may vary according to the bearing surface where the setup

must be installed.

For example, a setup installed on a concrete slab that is covering the bearing surface would

require cribbing consisting of only one plywood panel under the base while a setup installed on

a concrete slab that is covering an indoor garage would require shoring in addition to plywood

cribbing.

A setup installed on a bearing surface composed of gravel, sand or any such type of surface

would require stronger cribbing under the base.

In cases where shoring is required, it is recommended to contact an engineer for assistance.

WARNING

Make sure the ground or support surface capacity meets with values included in the

Minimum Bearing Surface Capacities table (fi g. 1.21). Soil compacting, cribbing or shoring

can increase bearing capacity. Any cribbing product or cribbing method approved by the site

engineer can be used to distribute the load on the bearing surface providing it meets the

values in the Minimum Bearing Surface Capacities table (fi g. 1.21). Contact an engineer for

assistance.

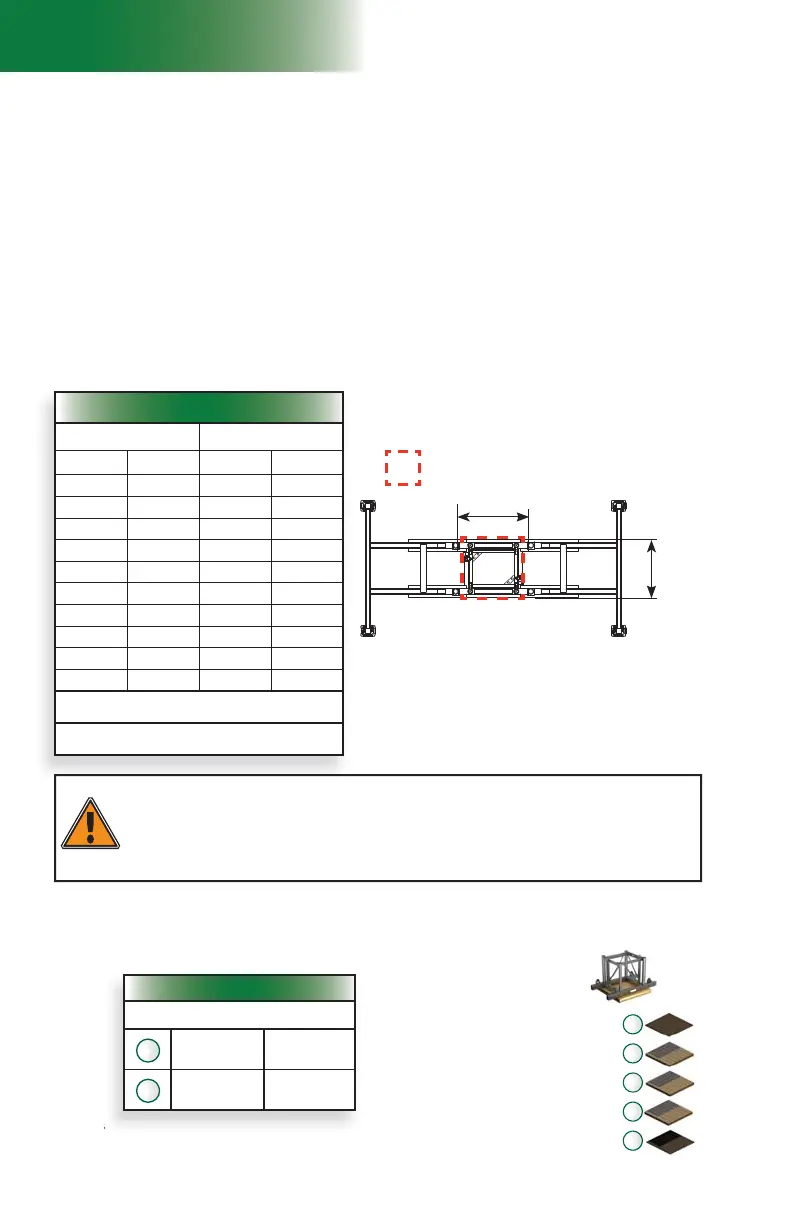

Minimum Bearing Surface Capacities

Minimum Bearing Surface Capacities

Height Reaction

ft m lb kg

50 15 28 816 13 071

100 30 32 559 14 769

150 46 36 302 16 466

200 61 40 045 18 164

250 76 43 788 19 862

300 91 47 531 21 560

350 107 51 272 23 257

400 122 55 017 24 955

450 137 58 760 26 653

500 152 62 503 28 351

Note: Reactions shown in this table are for tied

installations only

Load reactions in table above include a dynamic

factor

hown in the above table are

or re

erenc

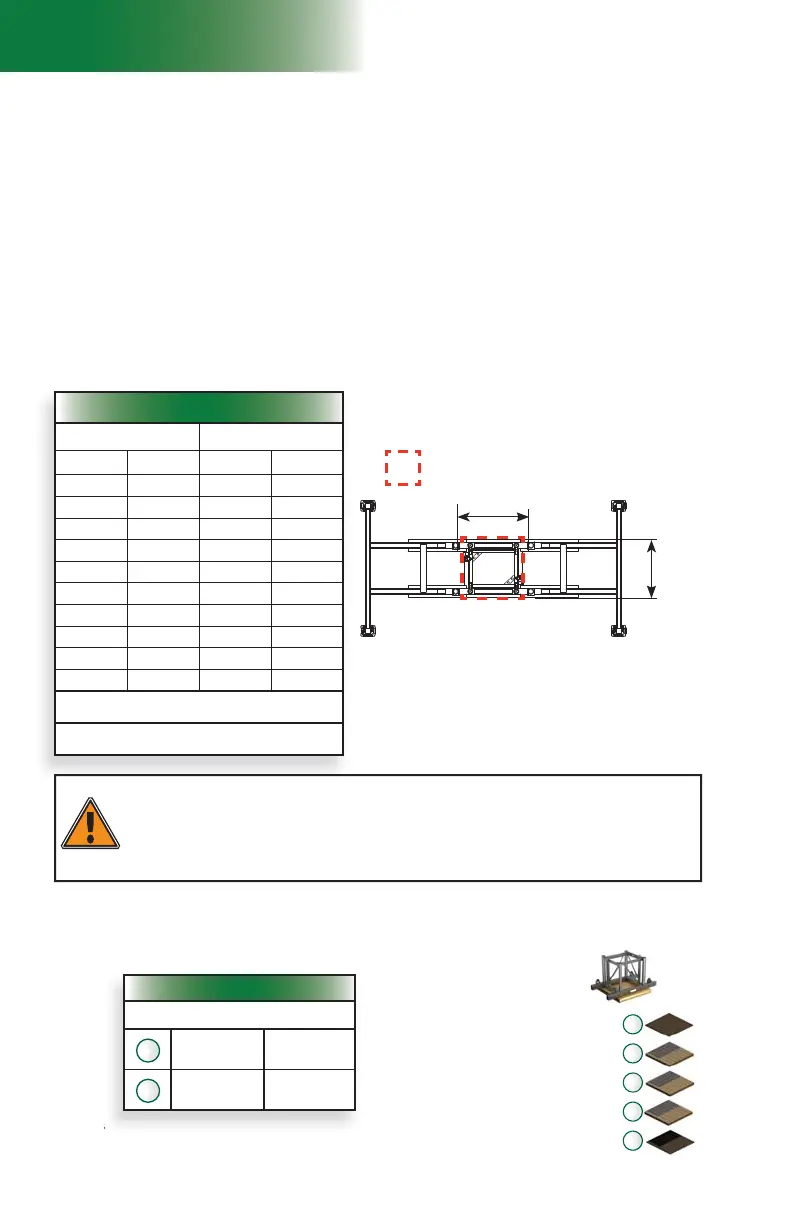

Recommended Cribbing

40" x 40" x 6"

(102 cm x 102 cm x

15,2 cm)

Plywood

40" x 40" x 3/4"

(102 cm x 102 cm x 1,9 cm)

2

Lumber

2"x 10" x 40"

(5 cm x 25 cm x 102 cm)

12

1

2

Plywood

3/4" (1,9 cm)

Lumber

1 1/2" (3,8 cm)

Plywood

3/4" (1,9 cm)

Lumber

1 1/2" (3,8 cm)

Lumber

1 1/2" (3,8 cm)

32" (81,3 cm)

32"

(81,3 cm)

Mandatory cribbing area

Loading...

Loading...