86

INSTALLER

USERMAINTENANCE TECHNICIAN

TECHNICAL DATA

3.7 TROUBLESHOOTING

Maintenance operations must be carried out by an authorised company (e.g. Authorised Aer-Sales Technical Assistance Cen-

tre).

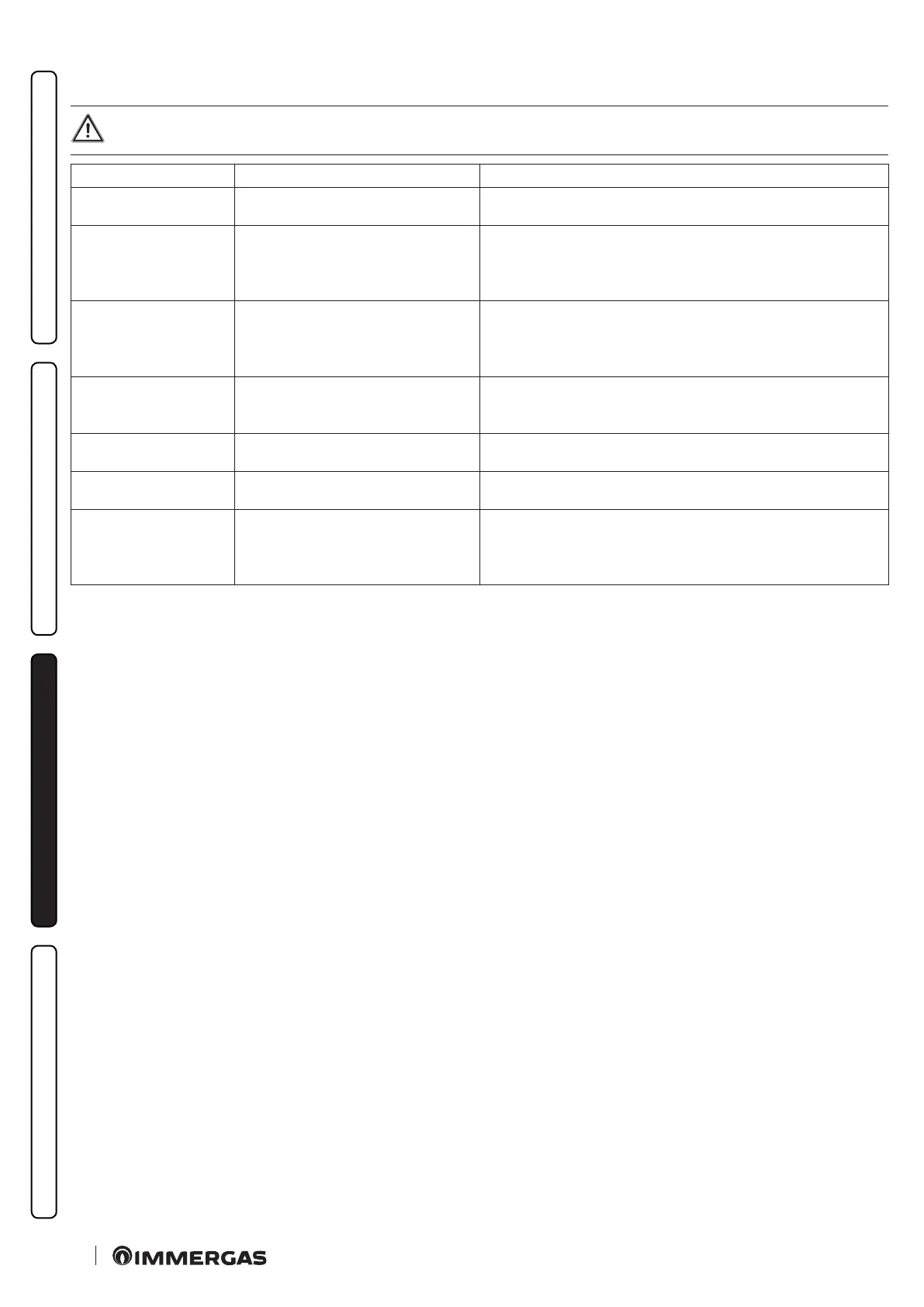

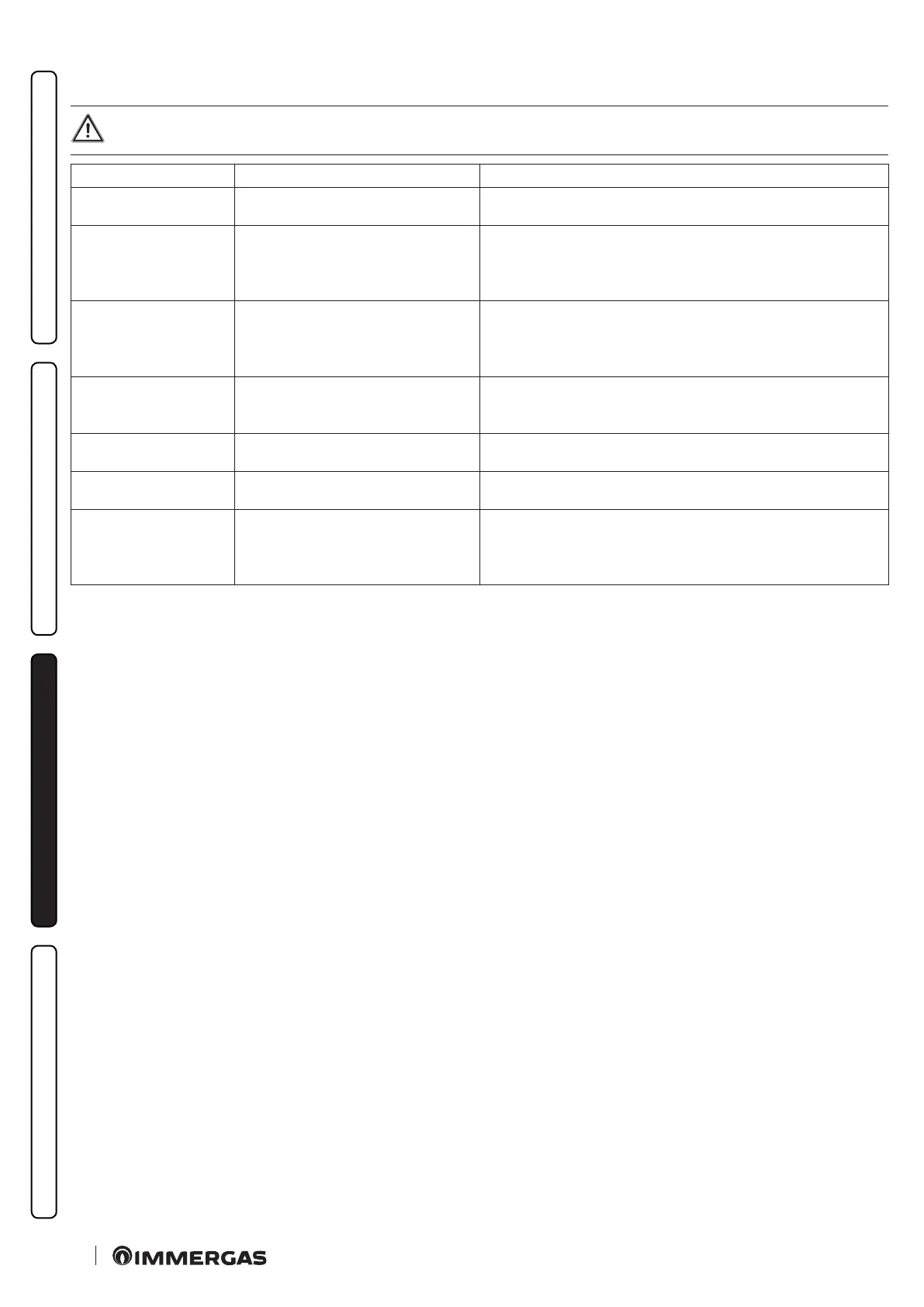

Trouble Possible causes Solutions

Smell of gas

Caused by leakage from gas circuit pipe-

lines.

Check sealing eciency of gas intake circuit.

Repeated ignition blocks No gas. Condensate drain clogged.

Check the presence of pressure in the network and that the gas adduction

valve is open. Restore the function of the condensate drain, checking that

the condensate has not aected: combustion components, fan and gas

valve. Check the function of the condensate sensor.

Irregular combustion or

noisiness

Dirty burner, clogged primary heat ex-

changer, incorrect combustion parame-

ters, intake-exhaust terminal not correctly

installed.

Check the indicated components.

Frequent trips of the

overheating safety device

thermostat function.

Lack of water in the appliance, little water

circulation in the system or blocked pump

(Parag. 1.32).

Check on the pressure gauge that the system pressure is within estab-

lished limits. Check that the radiator valves are not closed and also the

functionality of the pump.

Siphon blocked

Dirt or combustion products deposited in-

side.

Check that there are no residues of material blocking the ow of

condensate.

Heat exchanger blocked.

is may be caused by the drain trap being

blocked.

Check that there are no residues of material blocking the ow of

condensate.

Abnormal noises in the

system

Air in the system.

Make sure the system pressure and expansion tank factory-set pressure

values are within the set limits. e factory-set pressure values of the

expansion vessel must be 1bar (100 kPa), the value of system pressure

must be between 1 and 1.2 bar.

Loading...

Loading...