87

INSTALLER

USERMAINTENANCE TECHNICIAN

TECHNICAL DATA

3.8 CONVERTING THE APPLIANCE TO OTHER TYPES OF GAS

e gas conversion operation must be carried out by an authorised company (e.g. Authorised Technical Assistance Service).

For the gas change procedure, you must:

- Select, via programming menu "G", the type of gas by selecting "nG" for methane gas and "LG" for LPG gas (Parag. 3.13).

- Perform automatic calibration (Parag. 3.10). Check the CO

2

values via the chimney sweep function at the three reference powers (Par-

ag. 3.3). In case it is necessary to adjust the CO

2

values perform manual calibration (Parag. 3.11).

- Once the conversion has been carried out, ax the sticker for the relevant gas set in the connection box to the data nameplate (Fig.8).

Only for the Victrix Extra 12 Plus model: in the case of LPG gas setting, ax the sticker showing the relevant minimum power

contained in the warranty unit to the data nameplate (Fig. 8).

ese adjustments must be made with reference to the type of gas used, following that given in the table (Parag. 4.2).

Checks following conversion to another type of gas.

Aer having made sure that the conversion is complete and that the calibration has been successful, you must make sure that:

- there is no ame in the combustion chamber;

- the burner ame is not too high or low and that it is stable (does not detach from burner);

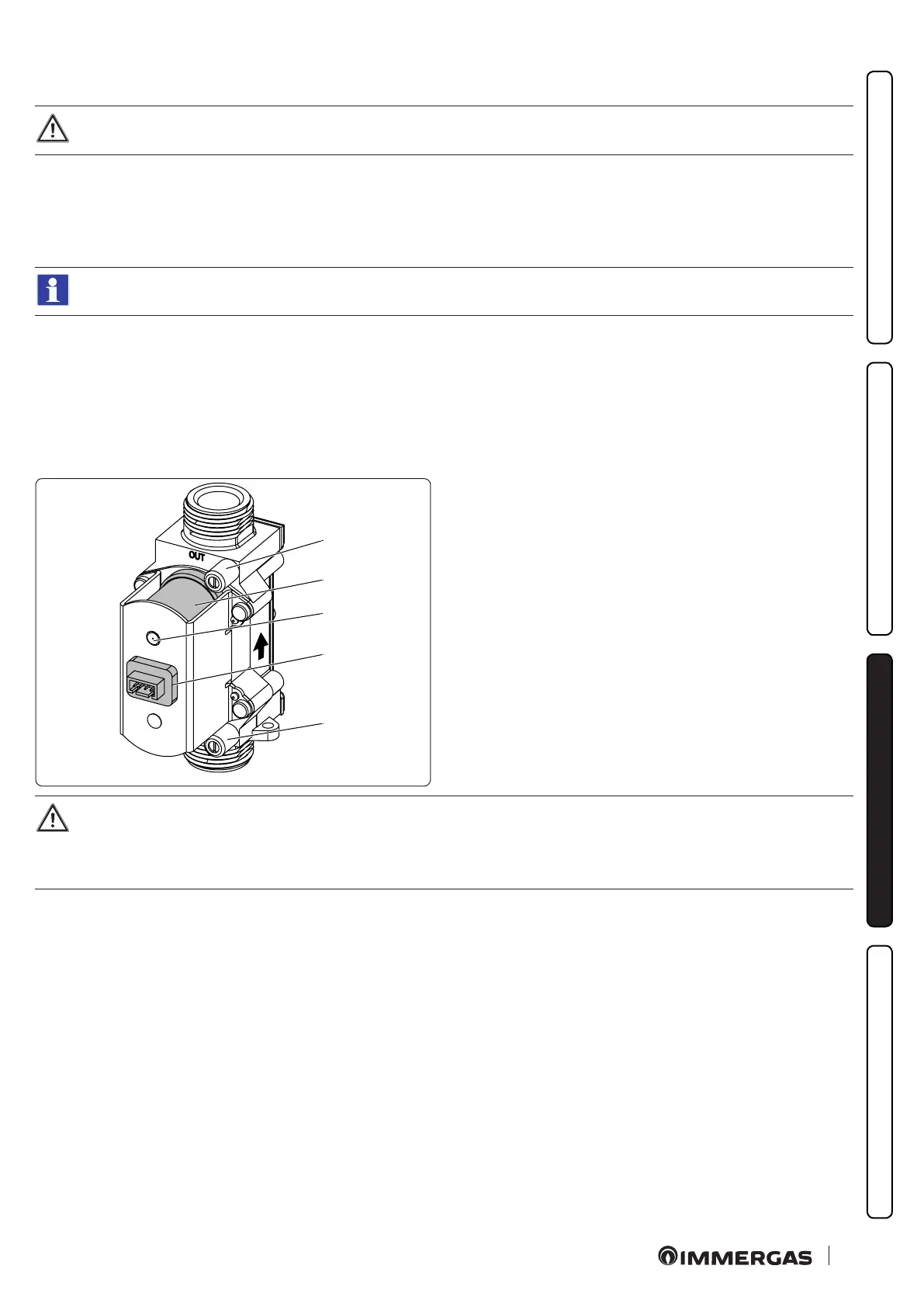

SGV 100 B&P GAS valve

1

4

3

2

5

55

Key (Fig. 55):

1 - Gas valve outlet pressure point

2 - Coil

3 - Wiring connector

4 - Gas valve inlet pressure point

5 - P. Ref. (Reference pressure)

Risk of material damage aer using sprays and liquids to search for leaks

Leak sprays and liquids clog the reference hole P.Ref. (Fig. 55) of the gas valve, damaging it irreparably.

During installation and maintenance, do not use spray or liquids in the upper area of the gas valve (electric connections side).

Loading...

Loading...