Shunt resistor may have hot surfaces during operation.

Shunt resistor overview and sizing

While decelerating a mechanical load (abrupt motion brakes or reversals), the mechanical energy is

converted into electrical energy by the motor. This energy is injected into the power supply and could lead

to an increase of the supply voltage (depending on the power supply characteristics, especially its output

capacitance) and then damage both the controller and the power supply.

A shunt circuit prevents the bus voltage from rising too high and therefore protects the Drive and the

power supply. It is based on a resistor (sometimes referred as braking resistor) that is connected between

the DC bus and GND through a power transistor.

This shunt transistor is automatically activated when the DC bus voltage exceeds a certain value defined

by the user. Its PWM duty cycle can also be configured by the user.

In general, a battery powered system is capable of absorbing regenerative energy and therefore no shunt

resistor would be needed. However only use this option if the battery is designed to accept negative

current peaks and does not provide a reverse current protection. This information must be provided by

the battery manufacturer. Reverse currents might cause catastrophic battery failure.

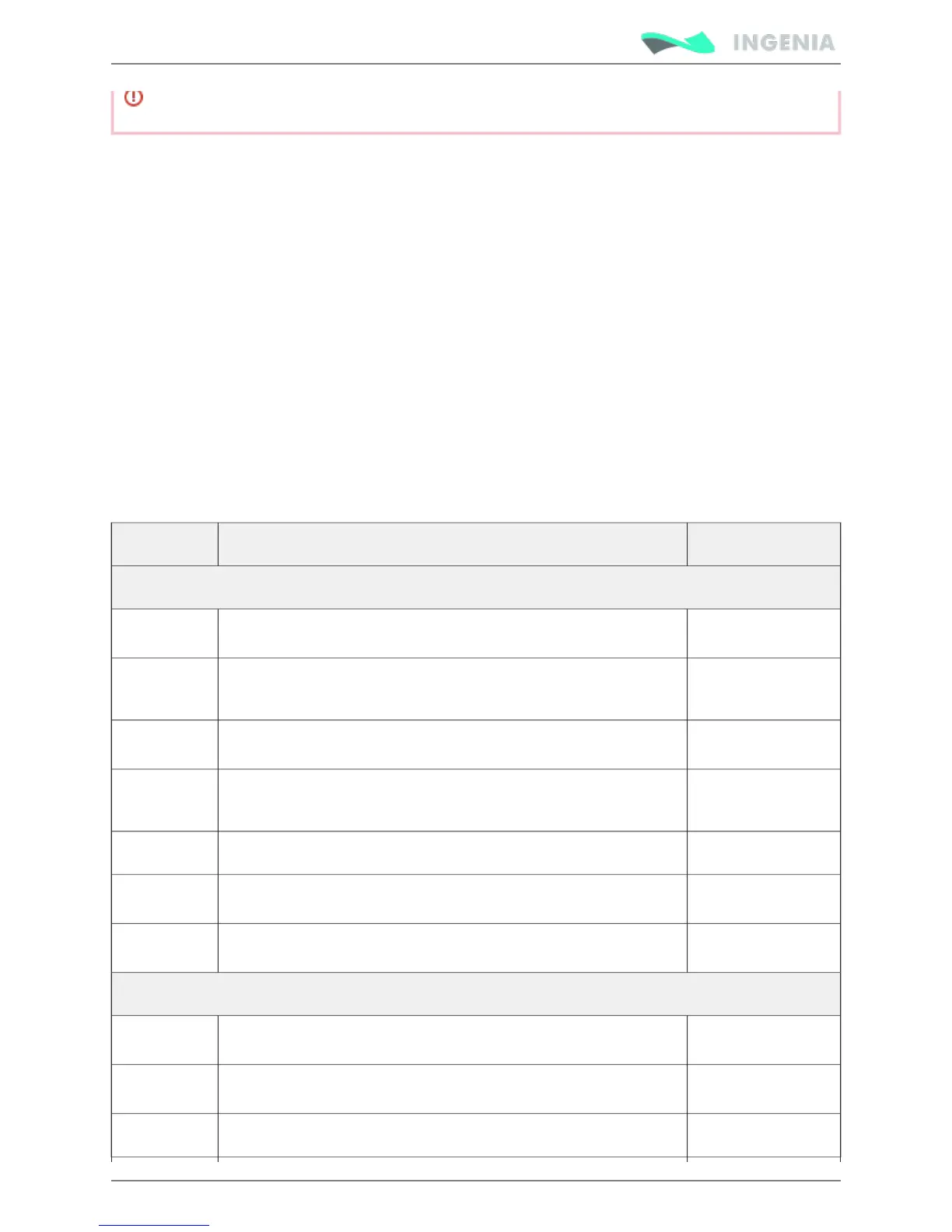

Shunt Resistor Sizing

To size the shunt resistor, the parameters in next table should be known or estimated.

Abbreviation Parameter Typical Value

Electrical parameters

V

NOM

Nominal Bus voltage [V] 12 V to 48 V

V

MAX

Turn on voltage for shunt circuit, user configured maximum Bus

voltage [V]

-

V

HYS

Hysteresis point of Bus voltage during deceleration cycles [V] -

C Bus capacitance [F] >112 µF (Pluto

Internal)

DC User configured shunt PWM Duty Cycle 0.5

I

PH

Phase current during deceleration [A ]

RMS

-

R

PH

Motor phase resistance line to line [Ω] -

Mechanical parameters

ω

M

Motor angular velocity before deceleration [rad/s = rpm · 0.1047] -

J

M

Motor moment of inertia [kg · m = N·m·s ]

2 2

-

Loading...

Loading...