109

FUEL SYSTEM

CARBURETOR SERVICE

6

HR Models Only

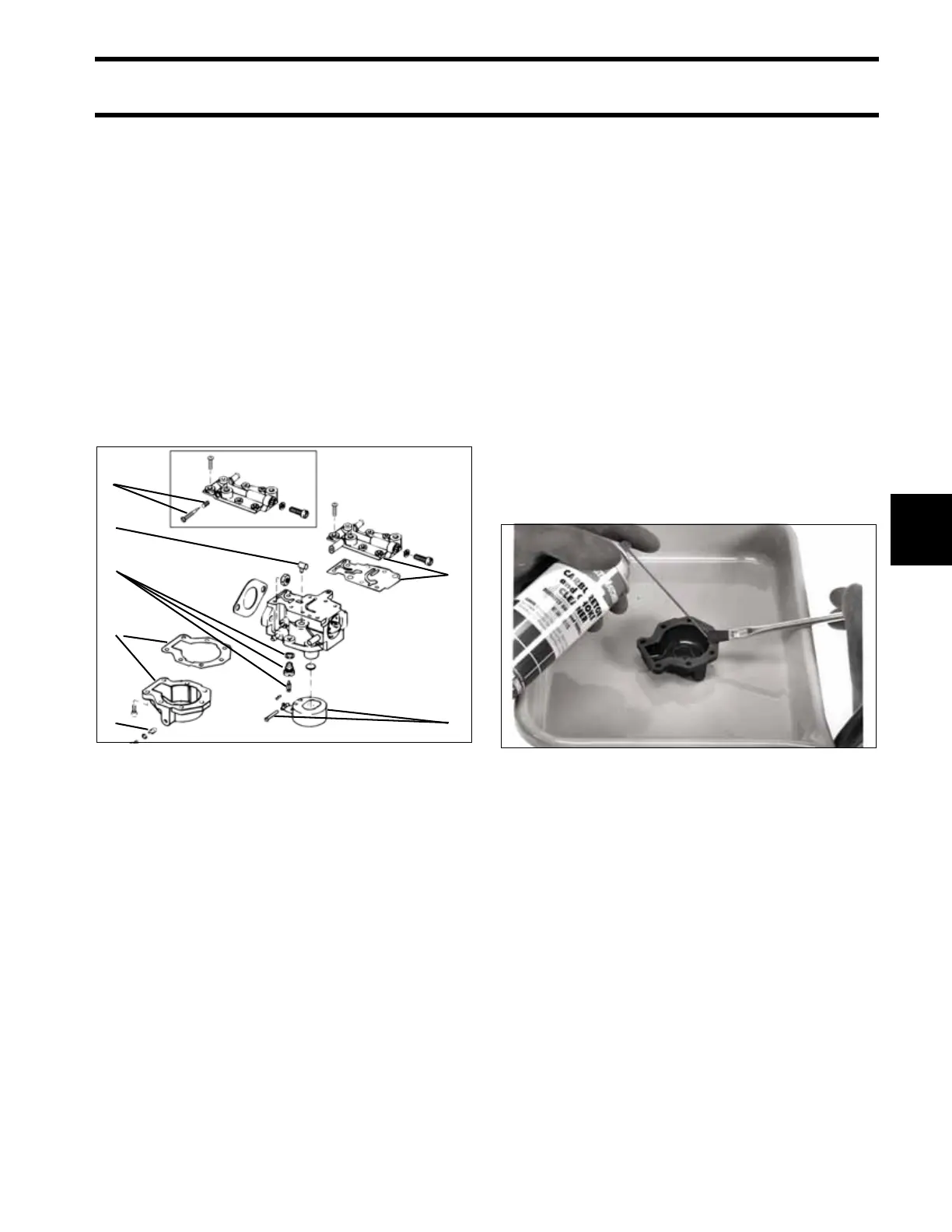

Remove the low-speed needle and spring from

the carburetor body cover.

All Models

Remove the six cover screws. Lift the cover and

gasket off the carburetor body.

Remove the seven float chamber screws and the

float chamber and gasket.

Remove the hinge pin, float, and inlet valve

assembly.

Remove the high-speed orifice. If necessary,

remove the air vent.

Refer to Cleaning and Inspection on p. 109.

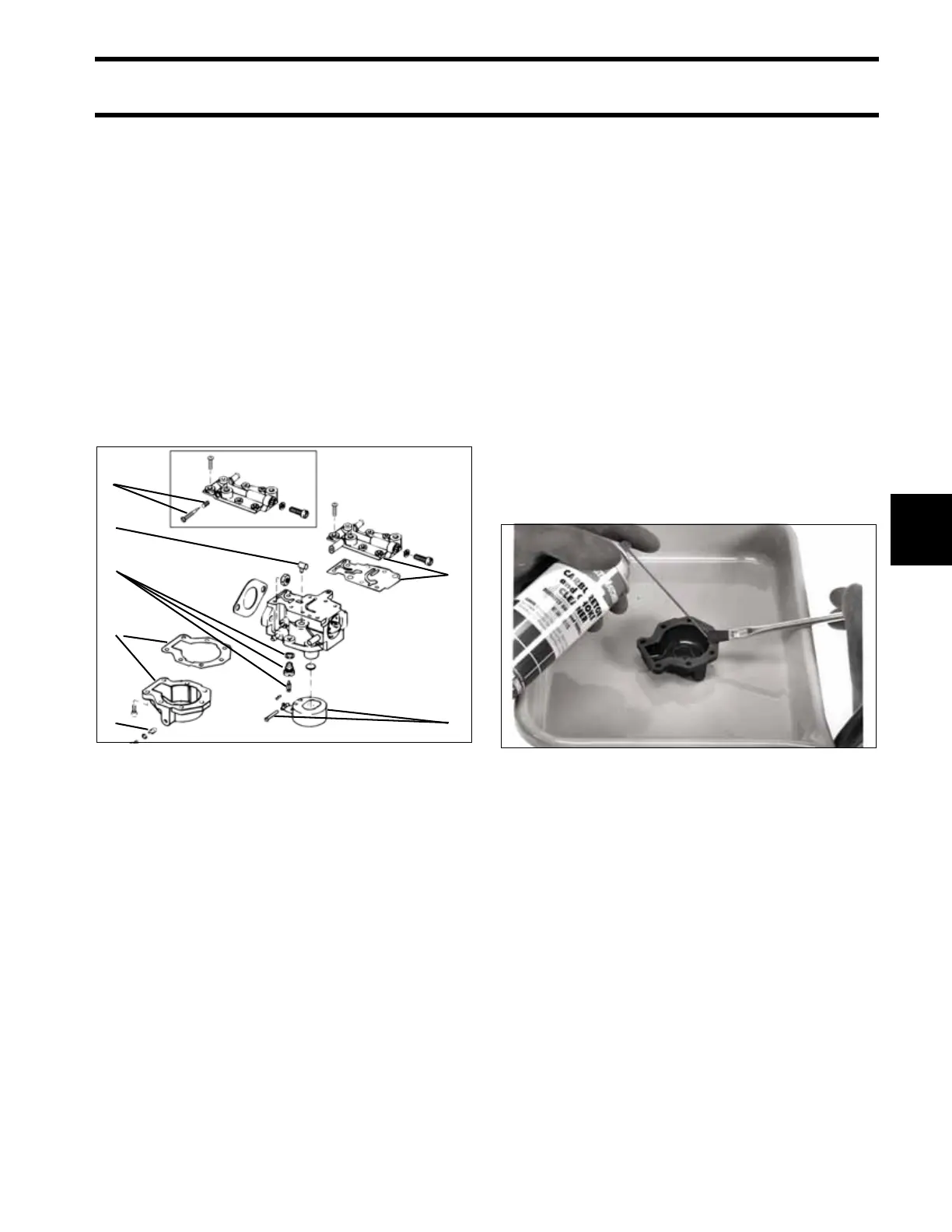

Cleaning and Inspection

IMPORTANT: Do not clean carburetor or its

components by submerging in strong carburetor

cleaner or hot soaking tank. Strong cleaners might

damage components or remove sealing com-

pounds.

Before inspection, all carburetor components

must be thoroughly clean.

• Carburetor must be completely disassembled.

• Clean parts with Carburetor and Choke

Cleaner.

• Use a clean bristle brush to remove gum or var-

nish deposits.

• Blow dry with shop air of not more than 25 psi

(172 kPa). When drying passages, direct the

flow of shop air opposite to the direction of fuel

flow.

Float Valve Assembly

Inspect the inlet needle and float valve seat.

• Check the float for signs of oil or gasoline satu-

ration.

• Check the float valve seat for nicks, scratches,

or distortion.

• Check the inlet needle tip for grooves, nicks,

scratches, or distortion.

1. Low speed needle and spring (10RH models only)

2. Carburetor body cover and gasket

3. Float chamber and gasket

4. Hinge pin and float

5. Inlet valve assembly

6. High-speed orifice

7. Air vent

002535

2

4

1

7

5

3

6

33953

Loading...

Loading...