175

GEARCASE

CLEANING AND INSPECTION

9

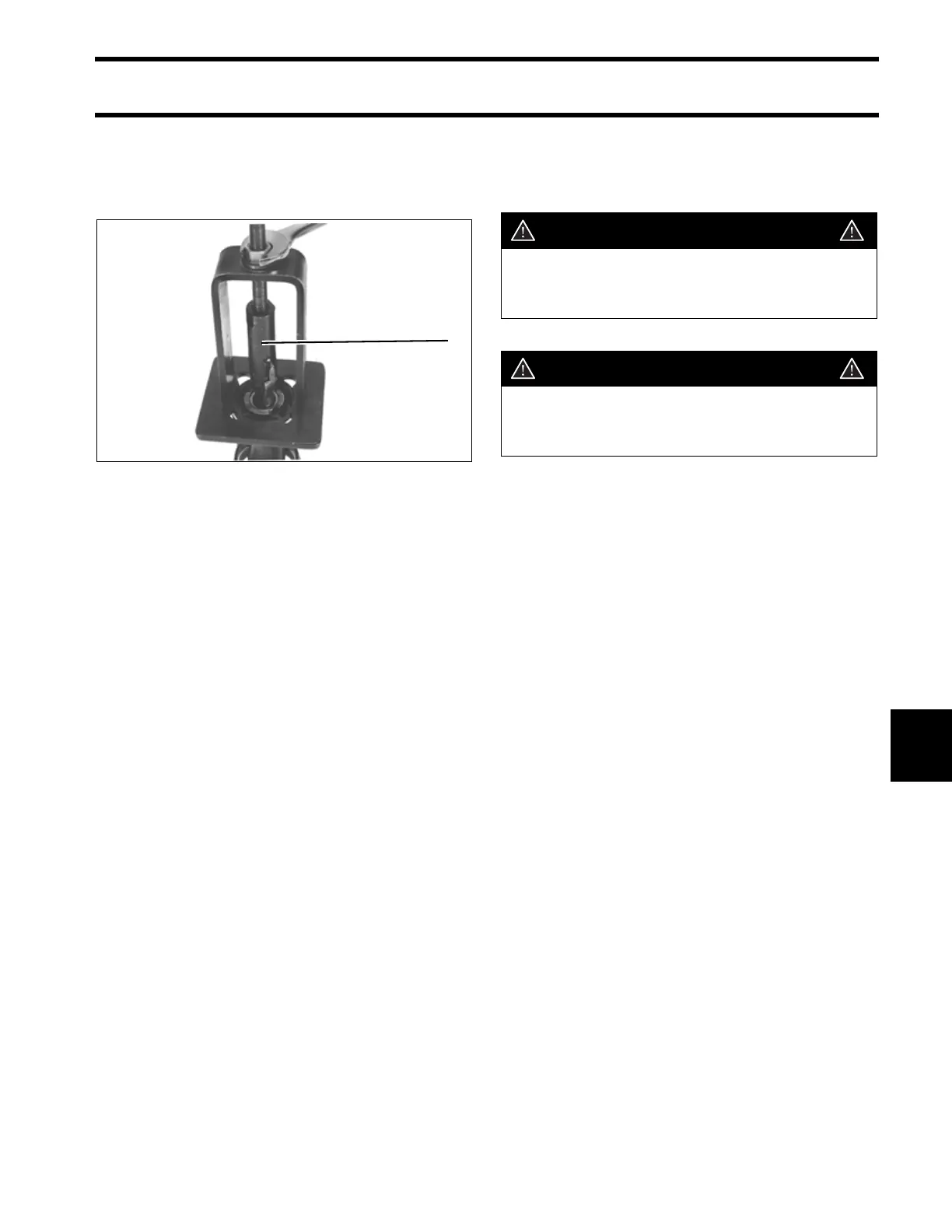

Using Puller Bridge, P/N 432127, and Bearing

Puller, P/N 432130, remove the larger propeller

shaft bearing located in the front of the bearing

housing. Discard the bearing.

CLEANING AND

INSPECTION

Discard all seals, O-rings, gaskets, and clutch dog

spring.

Clean all gearcase components in solvent and dry

with compressed air. After cleaning, coat all inter-

nal components with HPF XR gearcase lubricant

to prevent rusting.

Perform the following inspections:

• Gearcase housing — all gasket surfaces must

be free of gasket material. All threaded holes

must be free of corrosion and sealer.

• Gearcase anode — if anode has been reduced

to two-thirds of its original size, it must be

replaced. Refer to Anode Testing Procedure –

Continuity on p. 52.

• Driveshaft — check splines for chips, wear,

and cracks. Bearing and gear surfaces must not

show signs of metal transfer, corrosion, or dis-

coloration. Severe spline wear might indicate an

exhaust housing or gearcase has been dis-

torted by impact damage.

• Water intake screen — must be clear. If

screen can't be cleaned, it must be replaced.

• All internal components — must be visually

inspected for signs of wear, distortion, chipping,

metal transfer, pitting, galling, and discoloration

due to improper lubrication.

• Water pump — check impeller for wear, crum-

bling, and hub bonding. Check impeller cup and

plate for scoring and distortion.

1. Bearing puller 32546

1

WARNING

Replace damaged components. Shift sys-

tem failure could cause loss of control

over direction of engine thrust.

WARNING

To avoid personal injury, wear eye protec-

tion and regulate air pressure to not more

than 25 psi (172 kPa).

Loading...

Loading...