56

MAINTENANCE

LUBRICATION

Gearcase Lubricant

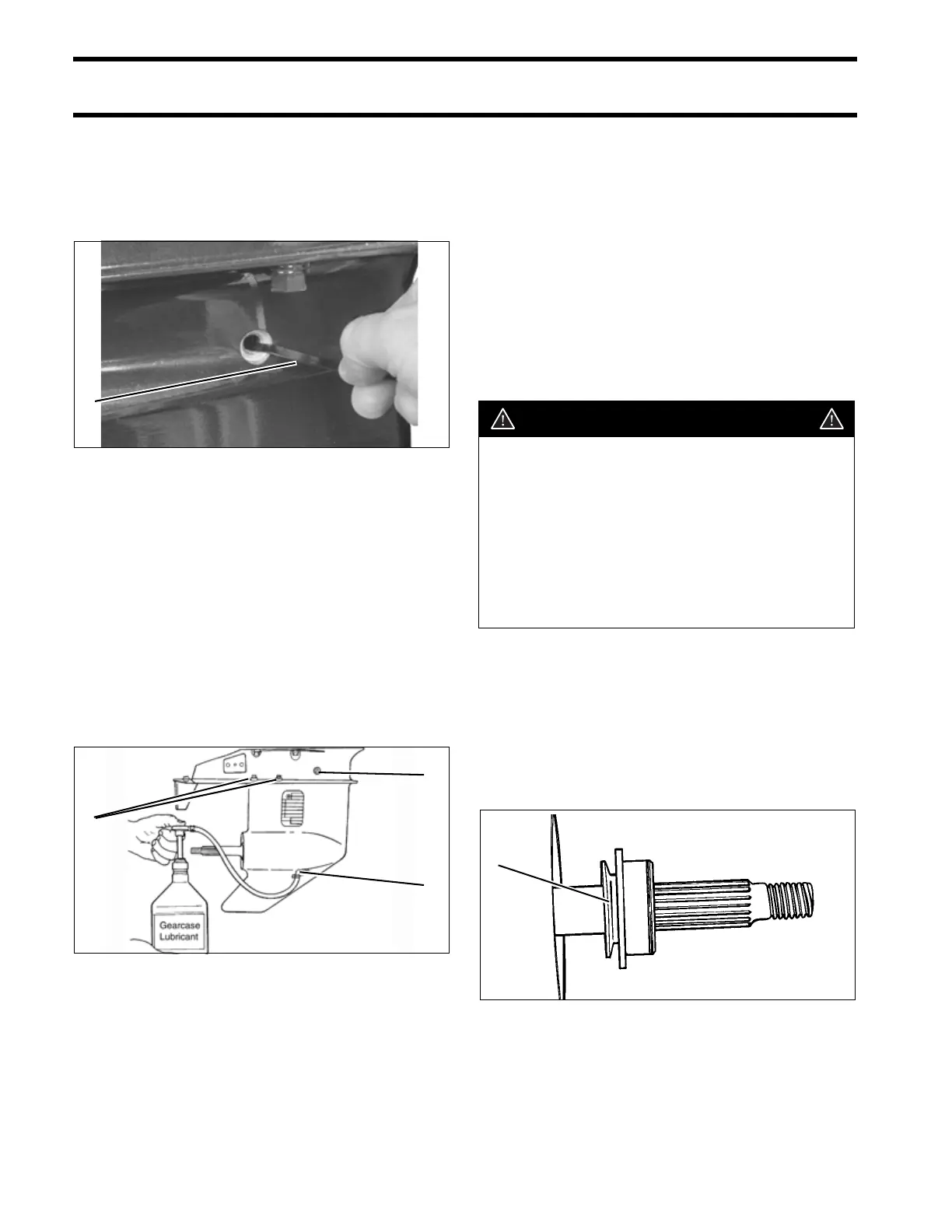

IMPORTANT: Always check the fill level of the

gearcase lubricant prior to removing drain/fill plug.

A tie strap can be used to check lubricant level.

Examine drained lubricant for excessive metal

fragments and for any indication of water in oil

(cloudy or milky appearance). Lubricant that is

black in color with a burnt odor indicates worn,

overheated oil. Pressure and vacuum check gear-

cases with apparent leaks. Repair all leaks.

Refer to INSPECTION AND MAINTENANCE

SCHEDULE on p. 50 for service frequency and

recommended lubricants.

Refer to LUBRICANT on p. 165 for complete

gearcase lubricant filling procedures.

REFILL the gearcase with HPF XR Gearcase

Lubricant.

If HPF XR Gearcase Lubricant is not available, Hi-

Vis gearcase lubricant can be used as an alterna-

tive; however, long term durability may be affected

with continued use.

IMPORTANT: The recommended gear lubri-

cants include special additives for marine applica-

tions. Do not use any automotive gear lubricants,

2-stroke or 4-stroke engine oil, or any other oil or

grease for gearcase applications.

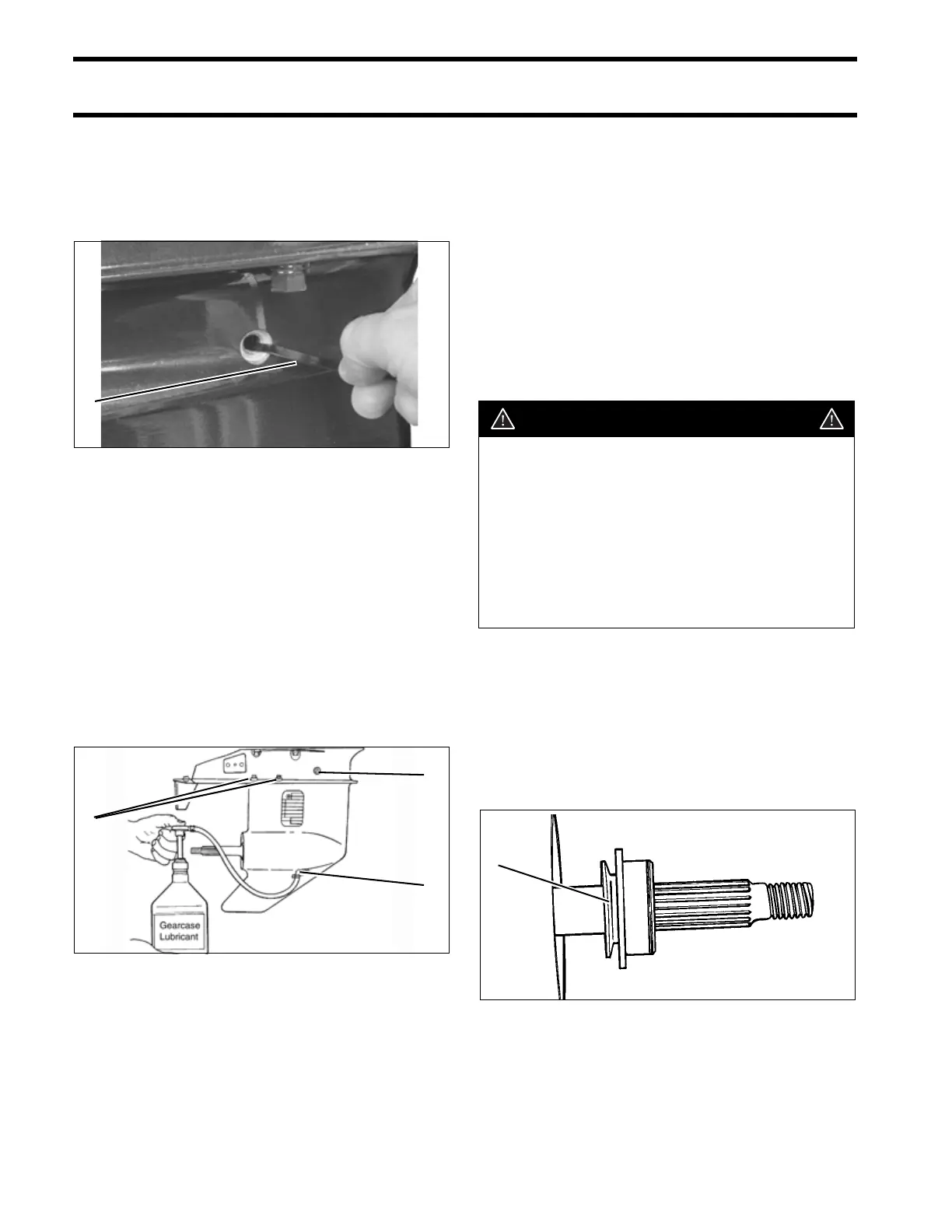

Propeller Shaft

Debris from the water can become lodged around

propeller shaft. Frequent inspection can minimize

potential gearcase damage.

Remove propeller. Refer to Propeller Hardware

Installation on p. 47.

Inspect bushing and blade surfaces. Replace

damaged or worn propellers.

Clean propeller shaft. Inspect propeller shaft

seals. Replace damaged or worn seals.

Apply Triple-Guard grease to entire length of pro-

peller shaft prior to installing propeller.

Reinstall propeller hardware and propeller.

1. Tie strap 000072

1. Drain/fill plugs

2. Drain/fill hole

3. Lubricant level hole

DR33673

1

3

2

1

WARNING

When servicing the propeller, always shift

the outboard to NEUTRAL position, and

twist and remove all spark plug leads so

the engine cannot be started accidentally.

Disconnect battery cables at battery on

electric start models to prevent accidental

starter engagement. Remove the battery

negative (–) cable first and the battery

positive (+) cable last.

1. Thrust bushing DR4310

1

Loading...

Loading...