79

ELECTRICAL

ELECTRIC STARTER SERVICING

4

Check permanent magnets and make sure they

strongly attract any steel or iron object held inside

frame. Weak magnets could cause excessive

RPM on No Load Current Draw Test on p. 77.

Do not clean drive assembly while the starter and

drive are installed. The cleaning agent could drain

into the starter, washing dirt from the drive into the

bearings and commutator. After disassembling,

clean each part with a grease solvent and inspect.

If the pinion does not properly engage the fly-

wheel, the pinion and screw shaft assembly may

be worn, distorted, or dirty. Locate the cause of

binding and correct it before completing the

assembly.

Assembly

Lubricate the armature shaft bearing surface with

Moly Lube. Lubricate the armature shaft on and

above the pinion helix with Starter Pinion Lube,

P/N 337016.

Assemble the brush end cap with brushes and

springs to the armature shaft. Place a new gasket

on the brush end cap.

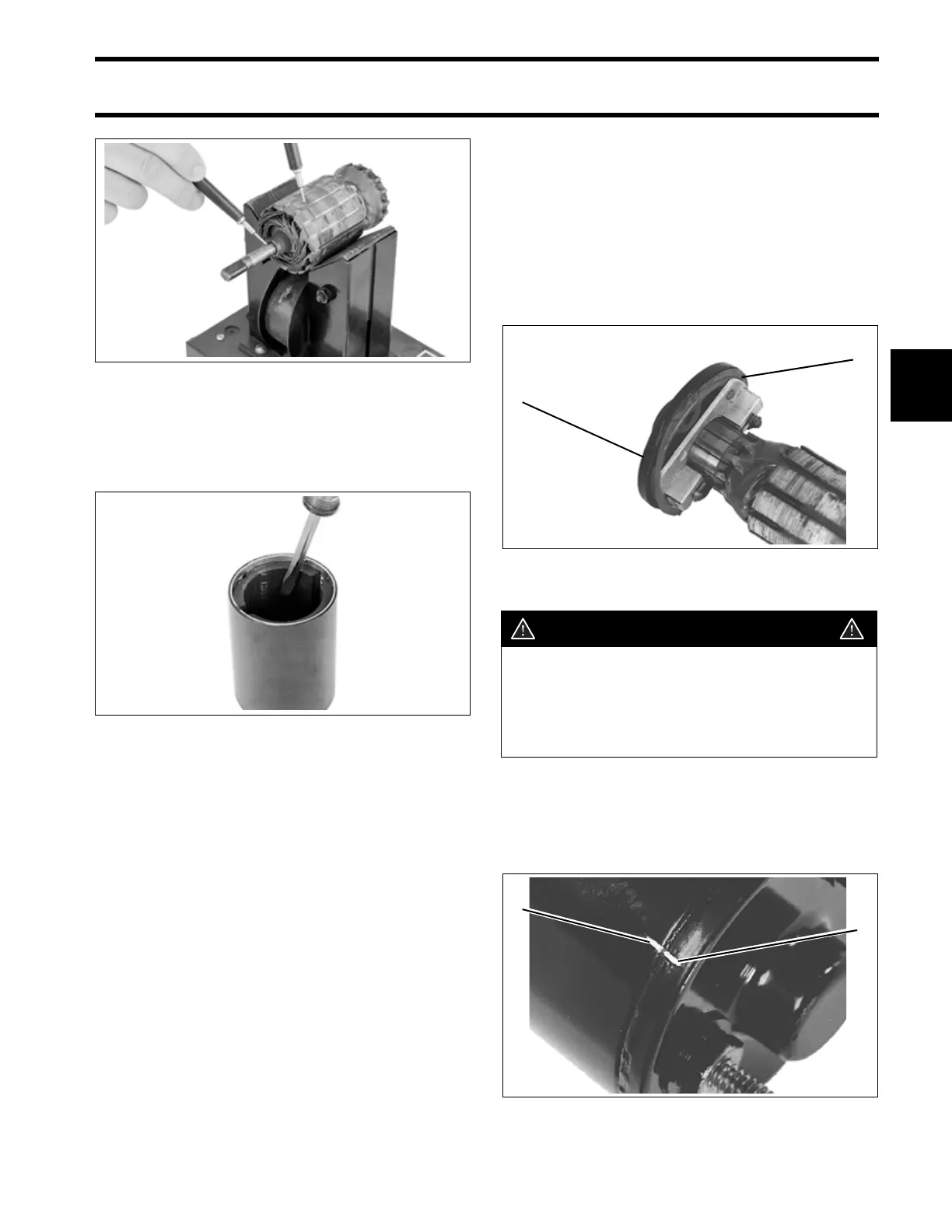

Align the brush end cap mark with the mark on the

frame and magnet assembly. Assemble the brush

end cap to the frame and magnet assembly.

24058

24057

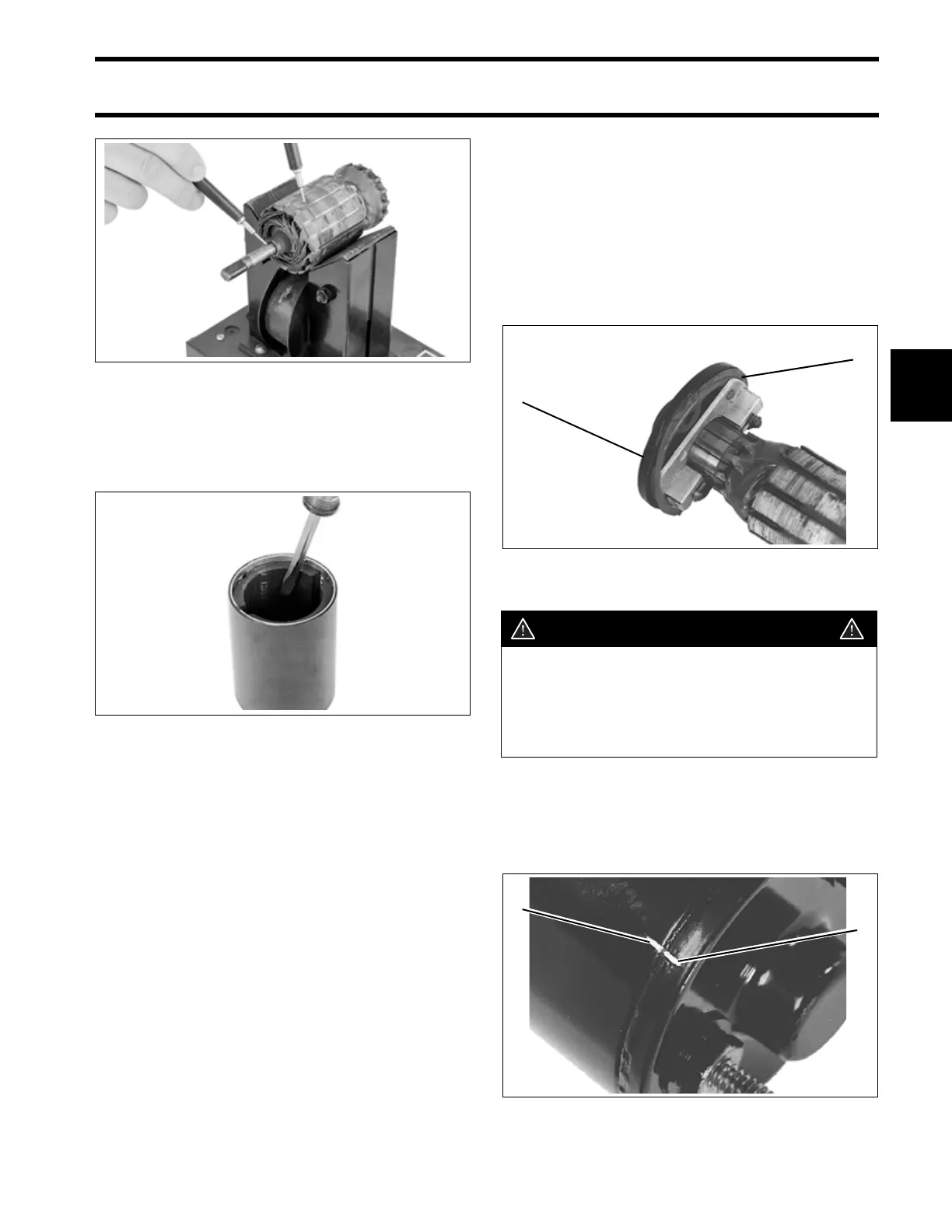

1. Brush end cap

2. Gasket

32982

WARNING

Use caution when inserting armature into

frame and magnet assembly as the perma-

nent magnets in the frame exert extreme

pulling force on the armature which could

result in pinched fingers.

1. Brush end cap scribe mark

2. Frame scribe mark

32981

1

2

1

2

Loading...

Loading...