62

MAINTENANCE

10-HOUR INSPECTION

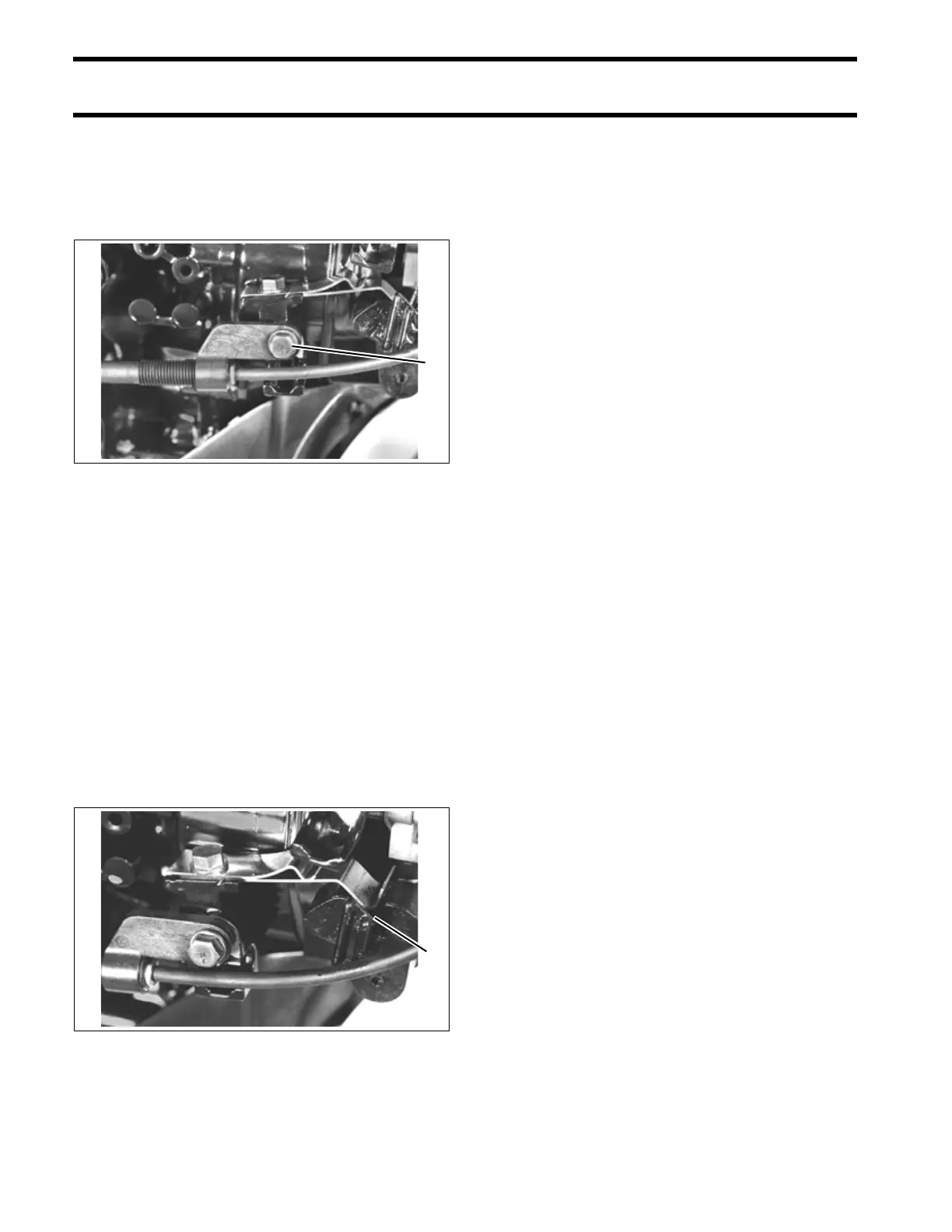

Remove the throttle cable bracket screw. Adjust

the throttle cable bracket to provide a slight pre-

load against the idle speed screw when Twist-Grip

throttle is held at the full throttle position (tiller

models).

Run outboard in gear at, or near, full throttle for

one minute. Quickly reduce engine speed to 700

RPM and shift into NEUTRAL. Engine should con-

tinue to run smoothly.

If outboard stalls or backfires, the idle fuel mixture

may be too lean. Refer to CARBURETOR MIX-

TURE ADJUSTMENT on p. 114.

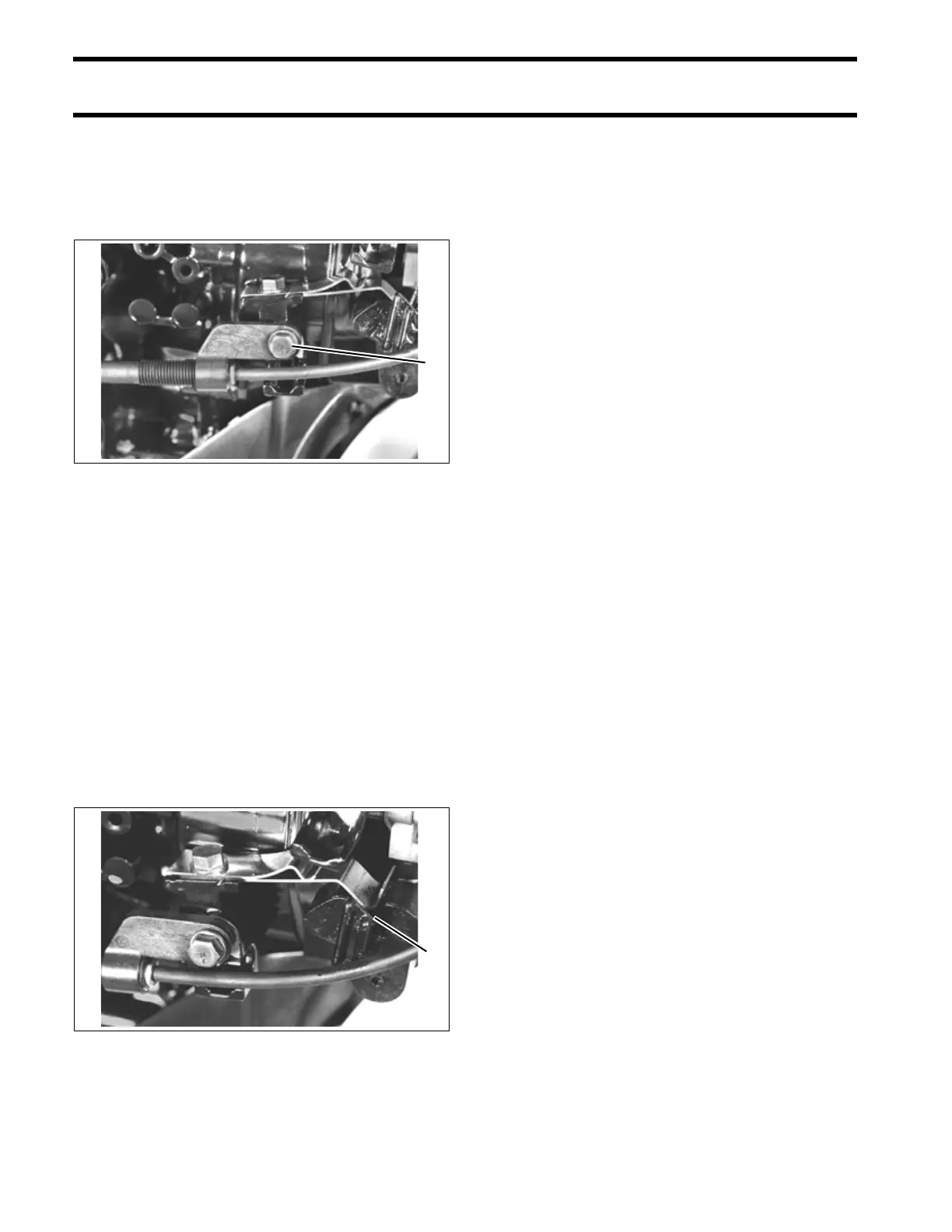

Shift Lever Detent

Rotate propeller shaft and move the shift lever to

NEUTRAL position.

The lower detent spring should be fully engaged

in notch of the shift lever detent.

10-HOUR INSPECTION

IMPORTANT: All Johnson outboard owners are

encouraged to return their new engines to an

authorized dealer for a mechanical check.

This check should be performed after approxi-

mately 10 operating hours. The cost of this check

should be figured at local dealer labor rates and

paid for by the engine owner.

The 10 hour inspection should check:

• Battery connections and condition

• SystemCheck and warning horn functionality

• Anticorrosion anodes functionality

• Water intake screens

• Overboard water pressure indicator functionality

• Steering system functionality (lubricate as

needed)

• Throttle and shift operation

• Emergency stop circuit and lanyard functionality

• Fuel system components, fix and repair any

leaks

• Fuel filter, eliminate any contamination

• Fasteners, tighten loose components

• Air silencer, clean and inspect

• Thermostat operation

• Engine to transom mounting hardware

• Electrical and ignition wires and connections

• Powerhead synchronization and linkage adjust-

ments

1. Throttle cable bracket screw 34784

1. Notch 34780

1

1

Loading...

Loading...