MAINTENANCE

INSPECTION AND MAINTENANCE SCHEDULE

51

3

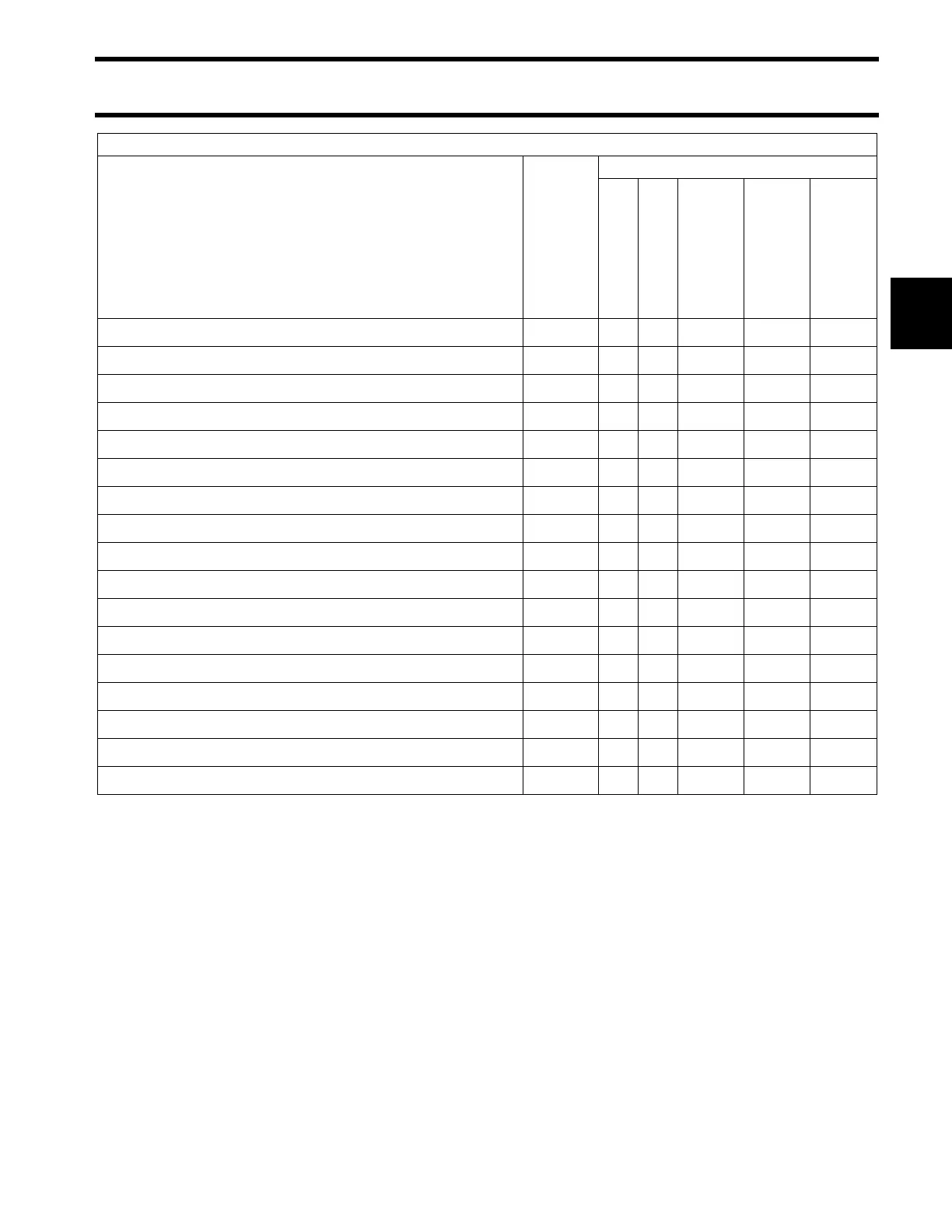

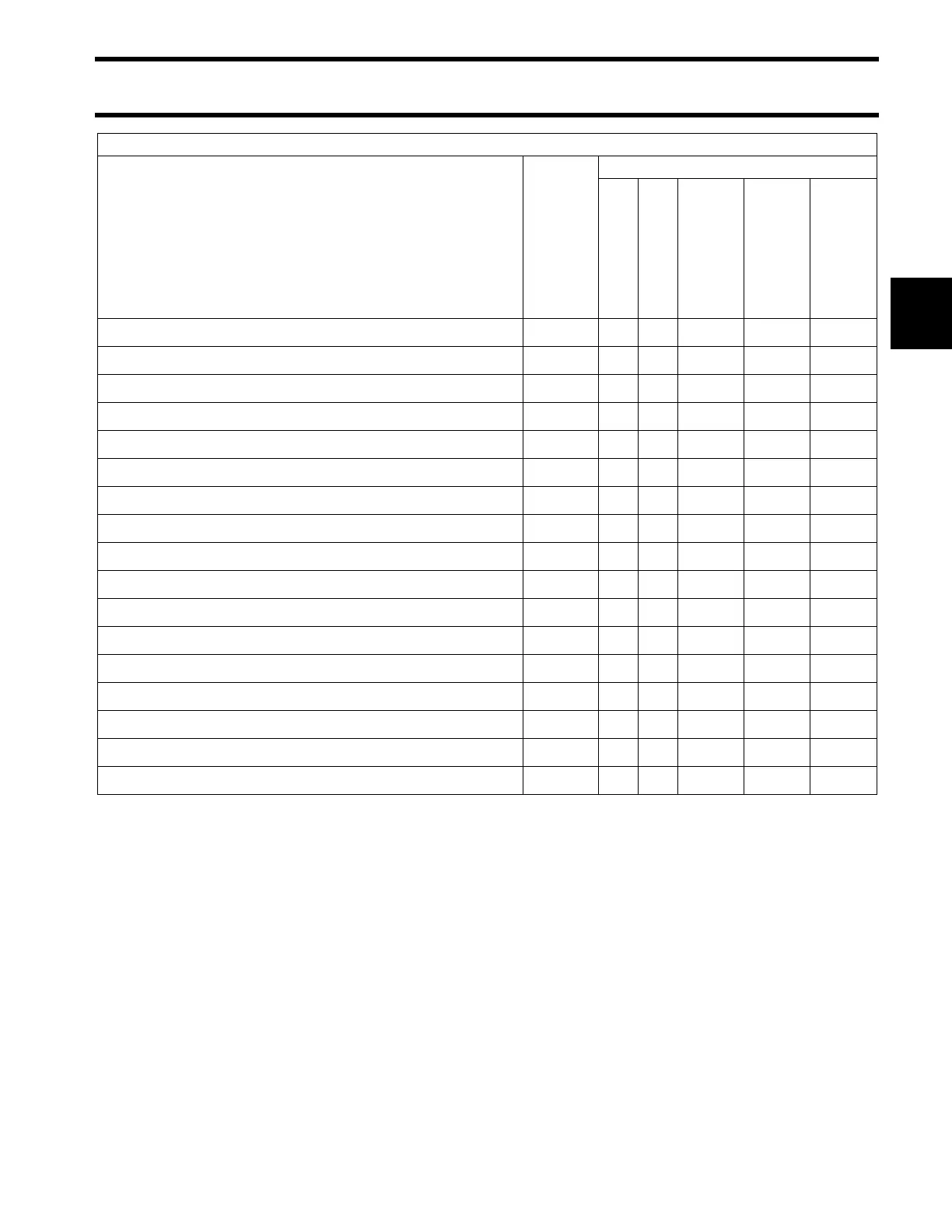

Fuel system components, inspect and repair leaks

(2)

33

Fastener inspection, tighten loosened components

33

Engine to transom mounting hardware, re-torque

33

Cam follower, inspect and lubricate

33

Thermostat, inspect and check operation

33

Spark advance linkage, lubricate

33

Electric starter, lubricate

33

Electrical and ignition wires and connections, inspect

33

Gearcase lubricant replace B

33

Powerhead synchronization and linkage, inspect

(2)

D

33

Gearcase lubricant, inspect fill level and condition of lube B

3

Starter pinion shaft, inspect and lubricate

(3)

F

3

Propeller shaft splines, inspect and lubricate D

3

Spark plugs, replace

(2)

3

Decarbonize G

3

Driveshaft splines, inspect and lubricate E

3

Water pump, inspect and replace

3

(1) Also recommended at 10-Hour Inspection

(2) Emission-related component

(3) Do not use light duty penetrating lubricants

A

Evinrude/Johnson Anti-Corrosion Spray or Evinrude/Johnson “6 in 1” Multi-Purpose Lubricant

B

HPF XR Gearcase Lubricant

C

Power Trim/Tilt and Power Steering Fluid

D

Triple-Guard grease

E

Evinrude/Johnson Molylube P/N 175356

F

Starter Bendix Lube Only P/N 337016

G

Evinrude/Johnson Engine Tuner

Engine Maintenance and Inspection Schedule

Description

Engine

Care

Product

Frequency

Each Use

10-Hour

Inspection

Every 50 Hours

or 6 months

Every 100 Hours

or Annually

Every 200 Hours

or Biannually

Loading...

Loading...