- 35 -

Starting up HandyTIG 180 DC ControlPro

10.15

Job saving

Set the welding machine as required.

Press key pad „1” 31 or „2” 29 for at least 3 sec-

onds.

9 LED 28 or LED 30 will light up twice to conrm.

Job selection

Shortly press key „1” 31 or „2” 29.

9 LED 28 or LED 30 will light up permanently to conrm

the selected job.

Job exit

Turn knob 27 or press key 25 or 26 shortly.

14.4 Access secondary parameter en

Press keys „1” 31 and „2” 29 shortly at the time.

9 The 7-segment-display shows alternating the param-

eter-code and the corresponding adjustment value.

The adjustment value can be set by turning knob 27.

By pressing key „1” 31 or „2” 29, the previous or sub-

sequent secondary parameter will be displayed.

Depending on selected mode and function, different

secondary parameter are available.

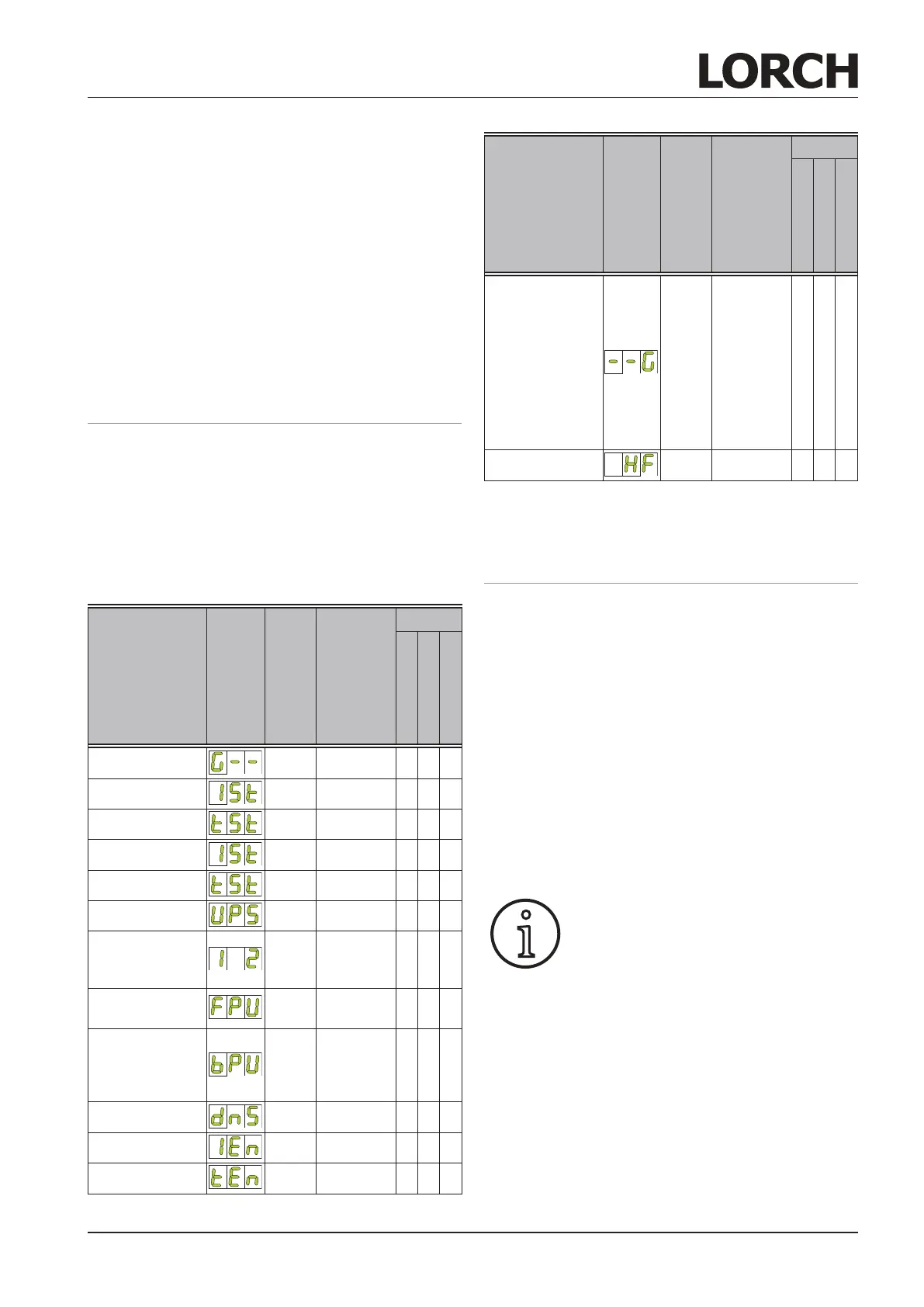

Parameter

Code

Factory setting

Adjustment

range

Mode

Electrode

TIG 2-stroke

TIG 4-stroke

Gas pre-ow time 0,1 s 0,1...10 s x x

Start current 50 % 5...200 % x x

Start current time 0,1 s 0,0...20 s x

Hotstart 125 % 5...200 % x

Hotstart time 1,0 s 0,0...20 s x

Upslope 5 % 0...99 % x x

Second current I

2

(% of welding

current I1)

50 % 1...200 % x x x

Pulse frequency 5,0 Hz

0,2...500

Hz

x x x

Pulse switch

frequency

(% part of weld-

ing current I1)

50 % 1...99 % x x x

Downslope 20 % 0...99 % x x

Final current 25 % 5...200 % x x

Final current time 0,2 s 0...20 s x

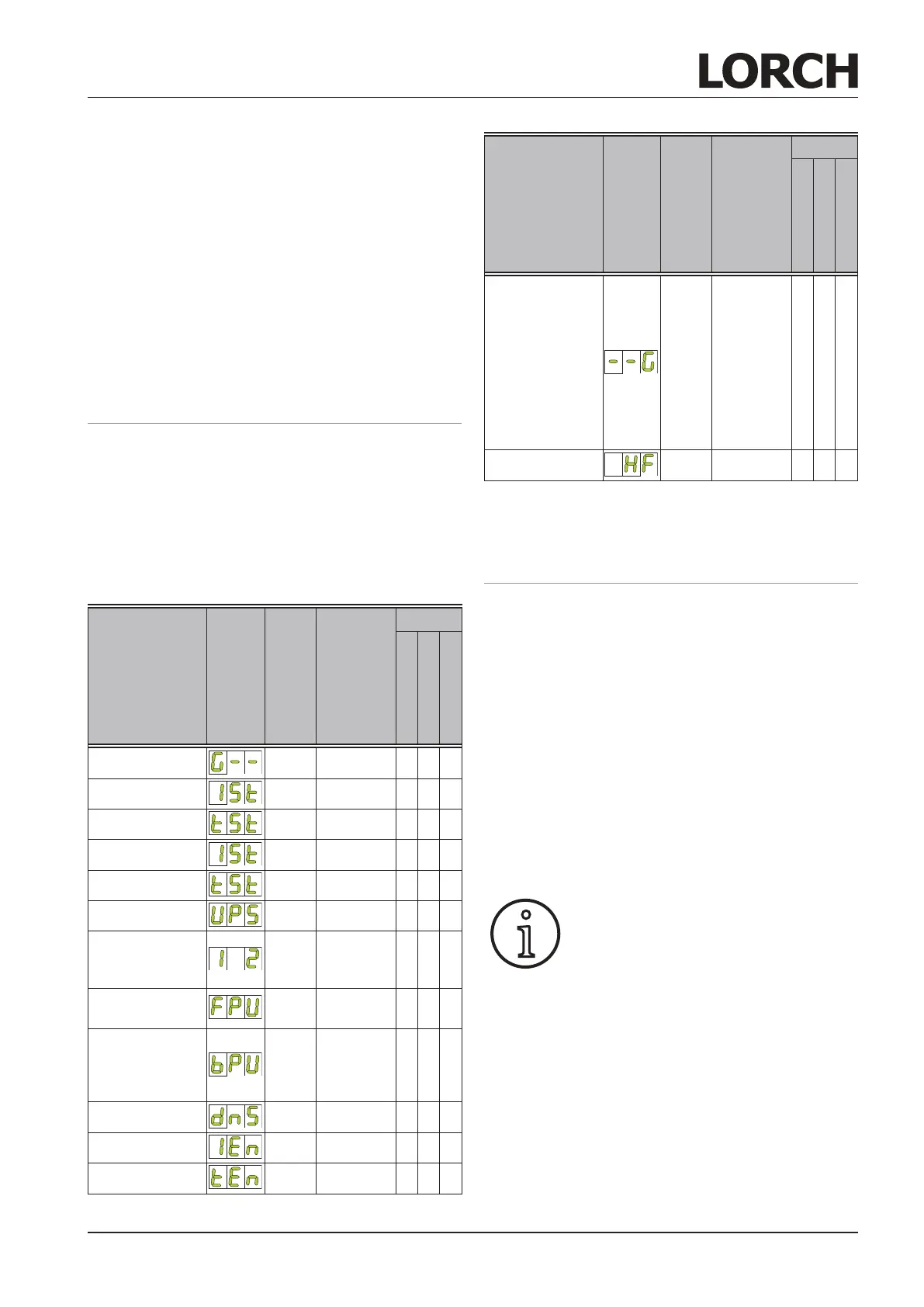

Parameter

Code

Factory setting

Adjustment

range

Mode

Electrode

TIG 2-stroke

TIG 4-stroke

Gas post-ow time

(in % depending on

welding current) at

100% correspond-

ingly

3 A --> 2 sec.

50 A --> 3,5 sec.

100 A --> 5,1 sec.

140 A --> 6,4 sec.

180 A --> 7,7 sec.

100 % 20...500 % x x

HF-ignition OFF OFF...On x

Tab. 3: Secondary parameters ControlPro

Press keys „1” 31 and „2” 29 shortly and at the same

time to exit the secondary parameter.

14.5 Special functions

Gas test, control panel test

Press keys 25 and 26 at the same time and for at

least 2 seconds.

9 For about 30 seconds the gas valve will interconnect,

all operation displays will light up and the 7-segment

display 15 displays „GAS”.

Gas and operation test can be stopped by pressing

key 25.

Software-Version

Press keys 26 and 29 at the same time and for least

1 second.

9 Software-Version of operation panel and main board

will be displayed.(i.e. dsp 2.3, St 1.1).

Master reset

Attention! All personal settings will be

lost.

All welding and secondary parameters are

reset to their factory settings (master reset

function).

Press keys 25 and 31 at the same time and for at

least 5 seconds.

9 The 7-segment-display and all operation displays

LED 28 or LED 30 will light up shortly to conrm.

Loading...

Loading...