- 36 -

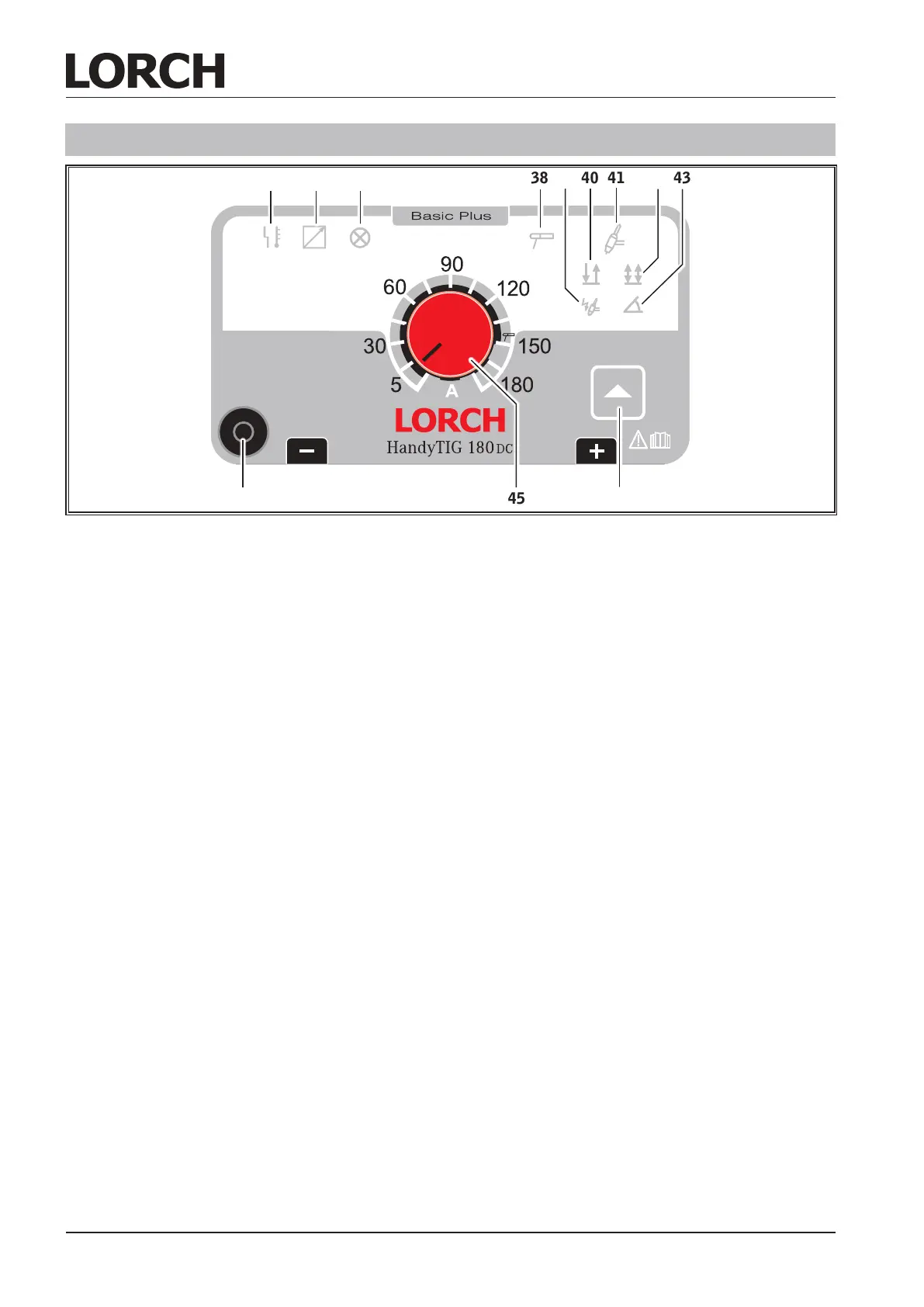

Starting up HandyTIG 180 DC BasicPlus

10.15

9 Torch control socket

plug the torch control plug into this socket.

35 LED malfunction

is lit constantly when the machine is over-

heated, LED ashes in case of a malfunction.

Ignition of an arc is not possible.

The LED ashes in a self-test mode directly

after switching on the machine.

36 LED Remote

Hand remote connected:

LED lights up permanently, turning knob welding

current 45 without function, adjustment only pos-

sible at hand remote control.

Foot remote connected: LED lights up by activa-

tion of foot remote, turning knob 45 predenes

the maximum value for the adjustment range of

the foot remote. If i.e. 100A are set,

5A – 100A can be recalled with the foot remote.

37 LED mains

is lit when the machine is operational.

38 LED MMA mode

is lit when MMA mode is selected.

39 LED HF

s lit when the HF function is activated, for con-

tactless ignition.

40 LED 2-stroke

is lit when 2-stroke mode is selected (only in

TIG mode)

press torch button = arc is ignitted

release torch button = arc goes out

41 LED TIG

is lit when TIG mode is selected.

42 LED 4-stroke

is lit when 4-stroke mode is selected (only in

TIG mode).

press torch button = ignition current ows

release torch button = welding current ows

press torch button = end current ows

release torch button = arc goes out

43 LED slope

is lit when function slope is activated.

2-stroke - at the start of the weling process the

machine rises the current from ignition current

to the selected welding current (upslope). At

the end of the welding process the machine

decreases the current from welding current to

min. current (downslope).

4-stroke - at the start of the weling process the

machine rises the current from start current to

the selected welding current (upslope). At the

end of the welding process the machine de-

creases the current from welding current to end

current (downslope).

44 Mode key

is used to select the different modes/functions.

45 Knob welding current

is used to set the desired welding current.

15 Starting up HandyTIG 180 DC BasicPlus

4335 36 37 38 40 41 42

9 45 44

39

Abb. 17: Control console 180 DC BasicPlus

Loading...

Loading...