Maintenance work on the superstructure

8.8 Hoist ropes

8 - 56 3 302 364 en Maintenance manual

GMK 4100L-1

25.11.2016

S

Risk of accidents due to reduced load bearing capacity.

Remember that other factors may also make it necessary to replace a rope

before the number of wire breaks requiring rope replacement has been

reached (age of rope, frequency of use or exceptional loading).

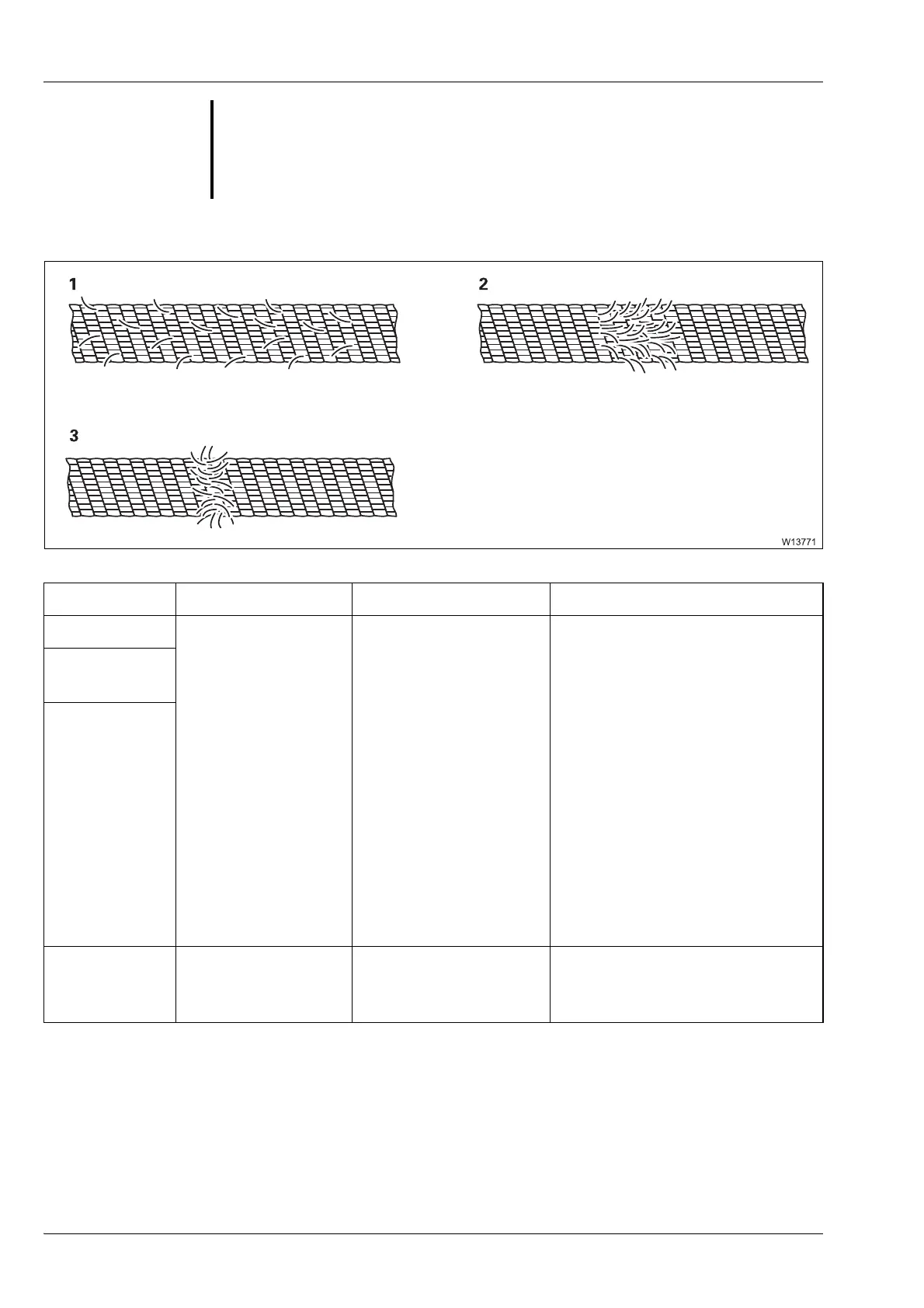

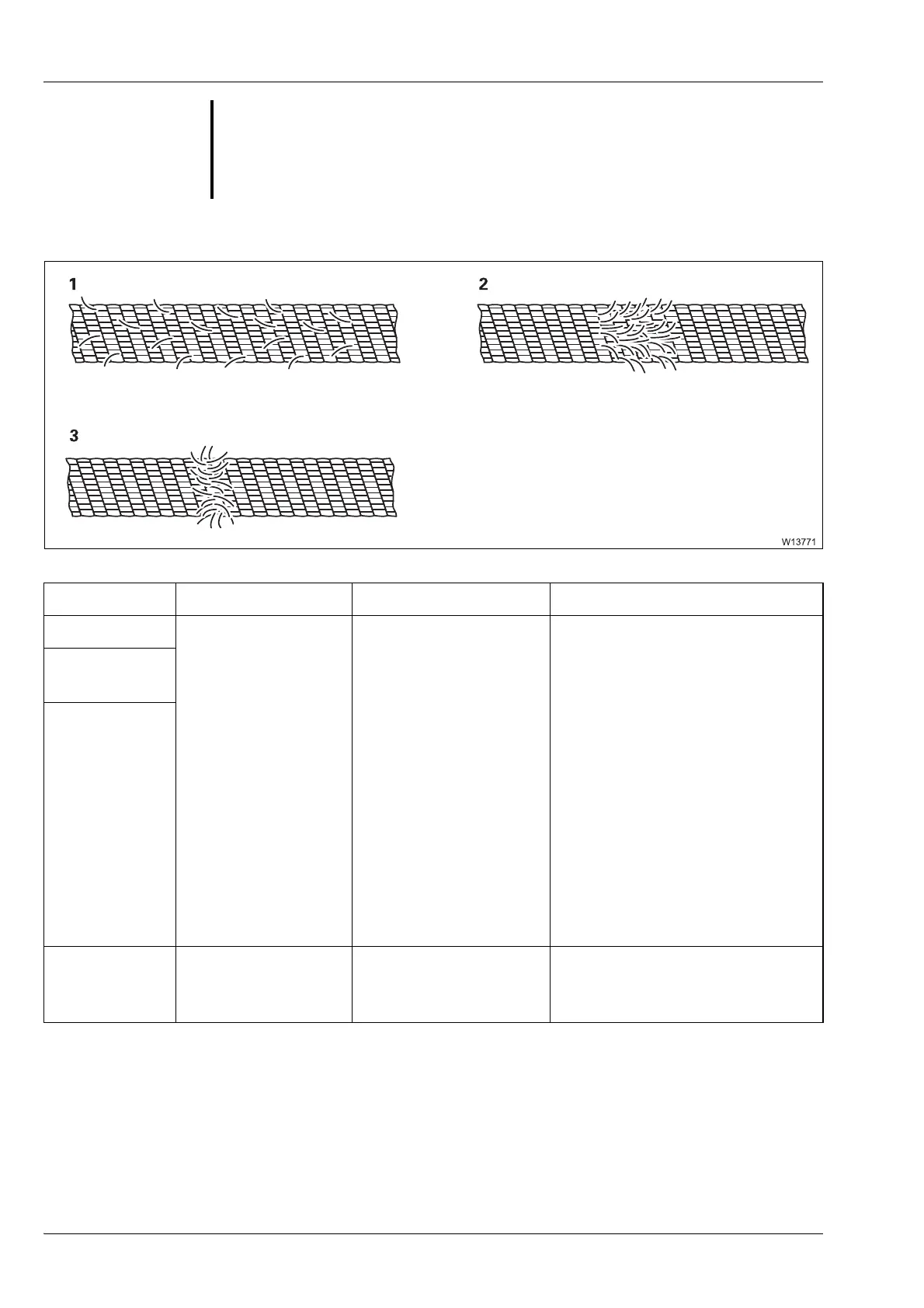

Damage Description Cause Replacement

Wire break (1) Individual wires are

br

oken; the broken

ends of the wires

are protruding

from the rope.

General wear caused

by ageing of the rope

or

consequential

damage as a result of

damage to the rope.

Replace the rope at the latest

when the maximum

permissible number of wire

breaks according to the table

are visible externally.

Replace the rope immediately if

wire wire breakage clusters or

strand breakages occur.

The frequency of wire breaks

increases with a rope's age. For

reasons of safety, it is advisable

to replace the rope while the

number of wire breaks is still

low.

Wire break-

age cluster (2)

Strand

breakage (3

)

Effect of heat Tarnishing colour

is

visible externally

on the rope.

Rope has been

subjected to excessive

heat.

Replace the rope immediately.

Loading...

Loading...