Maintenance work on the superstructure

8.9 Cable drums and slewing angle sensor

25.11.2016

Maintenance manual 3 302 364 en 8 - 67

GMK 4100L-1

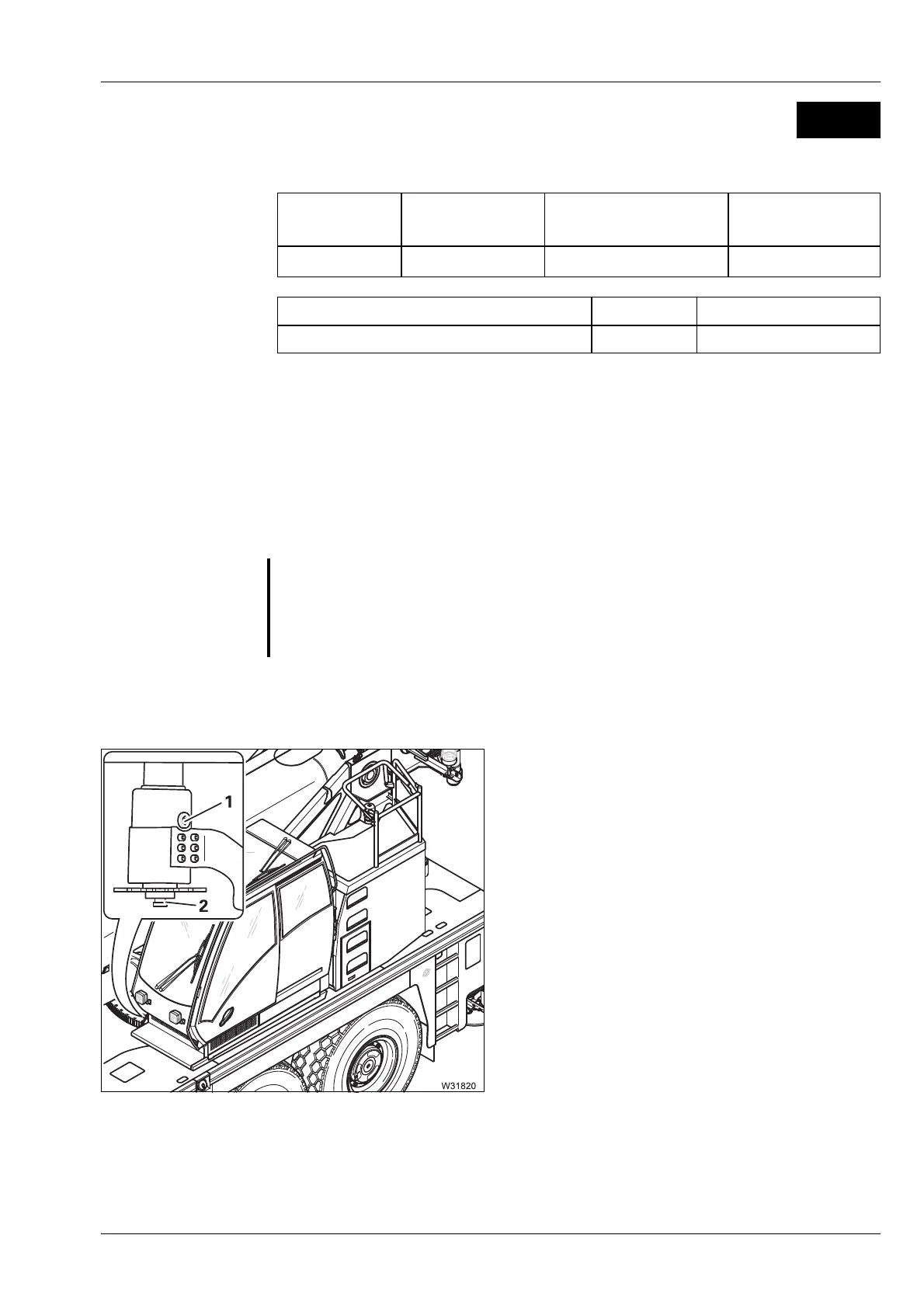

8.9.2 Lubricating the slewing angle sensor

Grease, spare

parts, tools

– Grease gun from the tool set.

– Sealing agent (e.g. Hylomar).

– Torque wrench for 25 Nm (18.5 lbf ft).

Prerequisites – The engine must be switched off and secured against unauthorised use;

à p. 2 - 3.

Lubricating

• Remove the drain plug (1).

• Clean the grease nipple (2) and inject about

5 cm³ (0.3 in³) of grease.

• Remove any excess grease, and close the

grease nipple.

• Tighten the bolt with a new gasket and

sealing agent – torque 25 Nm (18.5 lbf ft).

Lubricating

grease

Designation

to DIN 51502

Specification

classification

GROVE part no.

Grease KP - 1K - 50 DIN 51825 03233369

Designation Quantity GROVE part no.

Gasket 16 x 20 Cu DIN 7603 1 00117134

S

Risk of damage to the slewing angle sensor.

Before lubricating, always remove the screw from th

e slewing angle

sensor.

This prevents the slewing angle sensor from damage.

Loading...

Loading...