Maintenance work on the superstructure

8.10 Central lubrication system

25.11.2016

Maintenance manual 3 302 364 en 8 - 69

GMK 4100L-1

8.10 Central lubrication system

8.10.1 Checking the level

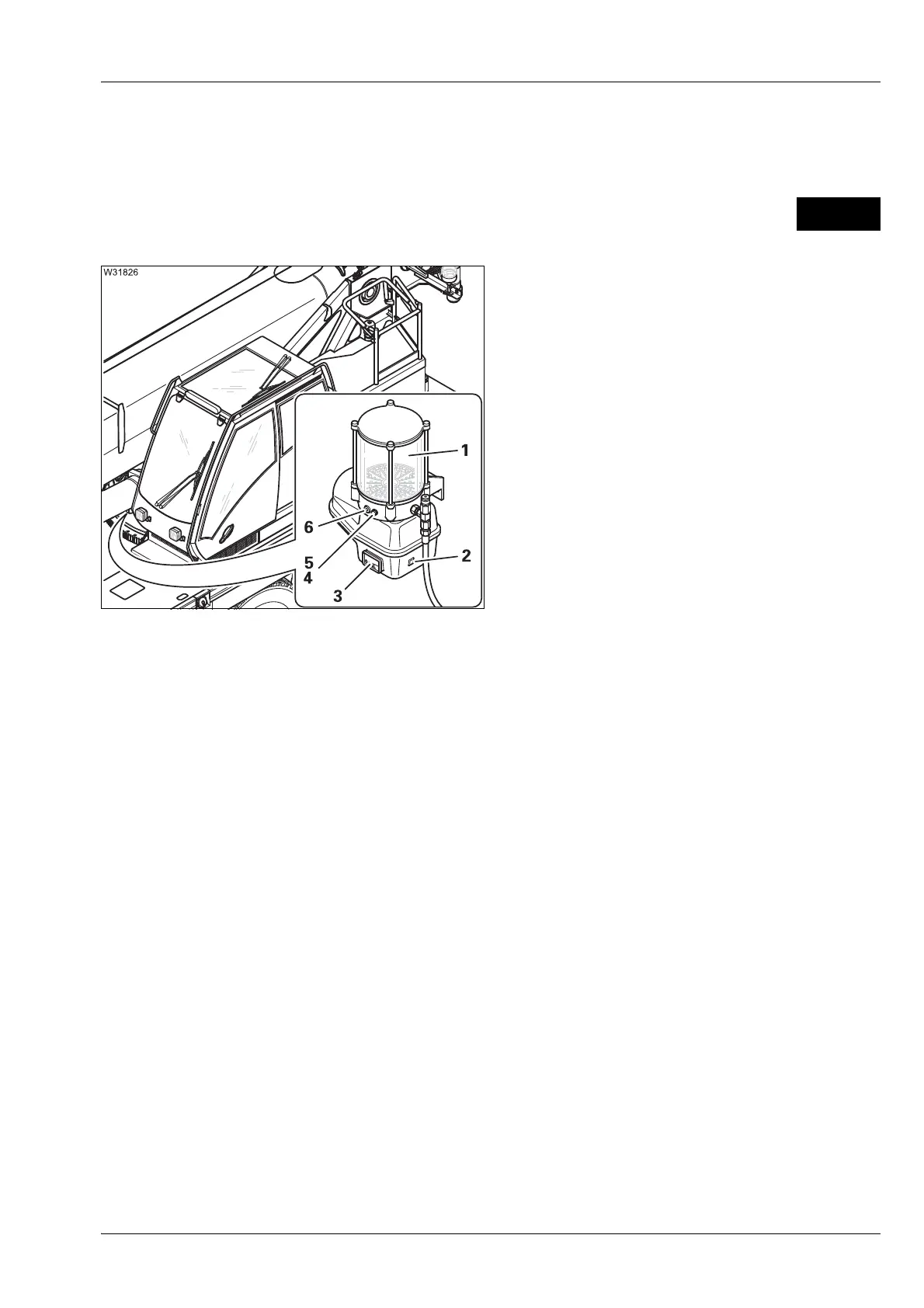

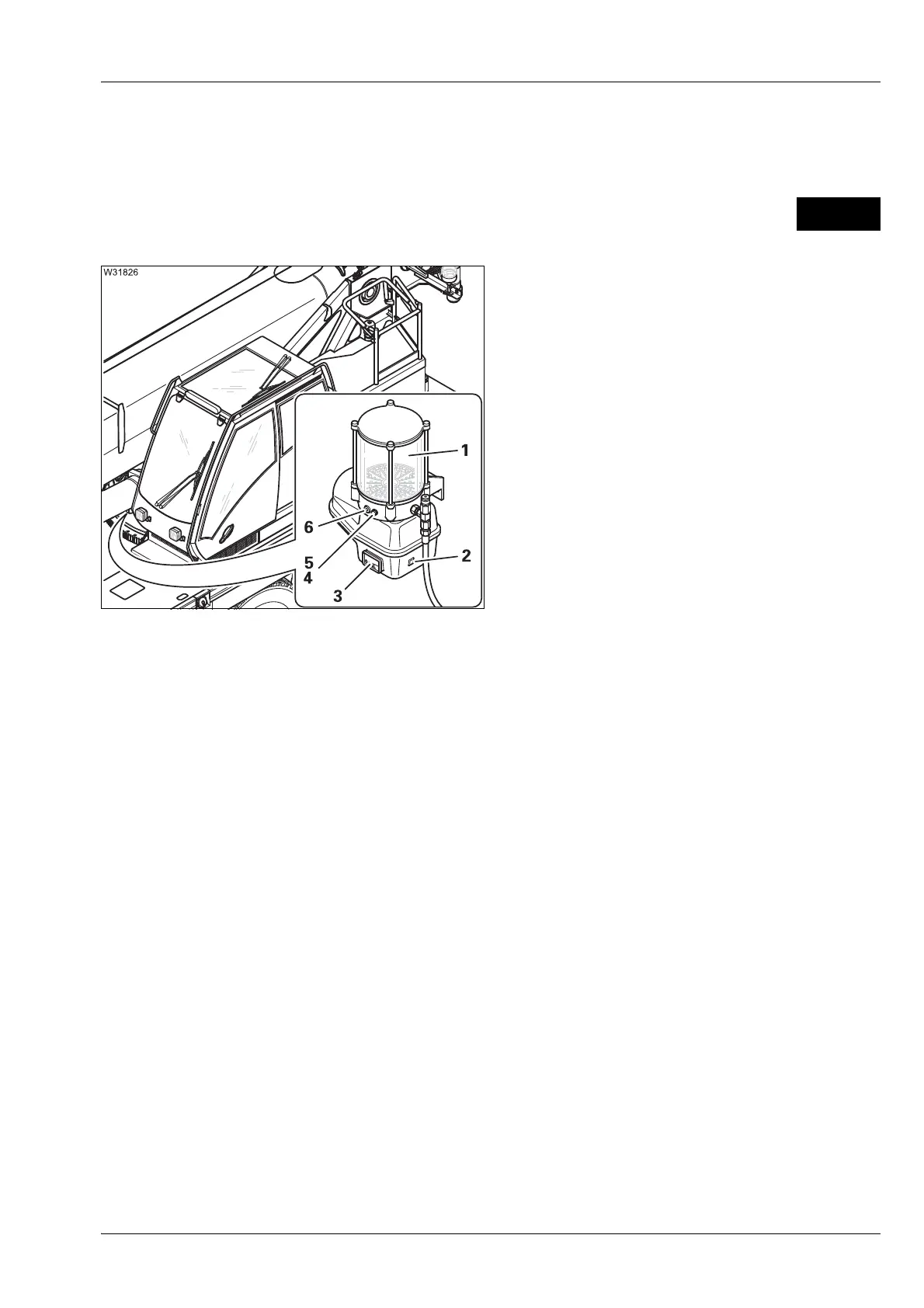

The maintenance of the pump (1) is similar

to the maintenance on the carrier;

à Central lubrication system, p. 7 - 115.

Connected lubricating points

– Main hoist drum,

– Auxiliary hoist carrier,

– Slewing bearing,

– Telescopic unit – pivot pins,

– Derricking cylinder – pivot pins

H

If necessary, initiate intermediate lubrication by pressing button (2). The

duration of the intermediate lubrication is about 6 minutes. The lights

(green = ready for operation, red = empty) are located on the display (3).

Topping up There are various options for filling the grease container (1):

4 Grease nipple (standard)

for connection of a manual grease gun.

GROVE part no. 04158709

5 Filling coupling plug (optional)

for connecting a the hose to a grease filling station with a drum.

GROVE part no. 04165387 straight; 04165388 angled

6 Filler connection (optional)

for the filling pump from the tool set.

To use this, the plug (6) must be removed

and the filler connection

from the tool box inserted in its place.

GROVE part no. 03137895

Loading...

Loading...