Maintenance work on the superstructure

8.9 Cable drums and slewing angle sensor

8 - 66 3 302 364 en Maintenance manual

GMK 4100L-1

25.11.2016

Maintenance of

the slip ring

assemblies

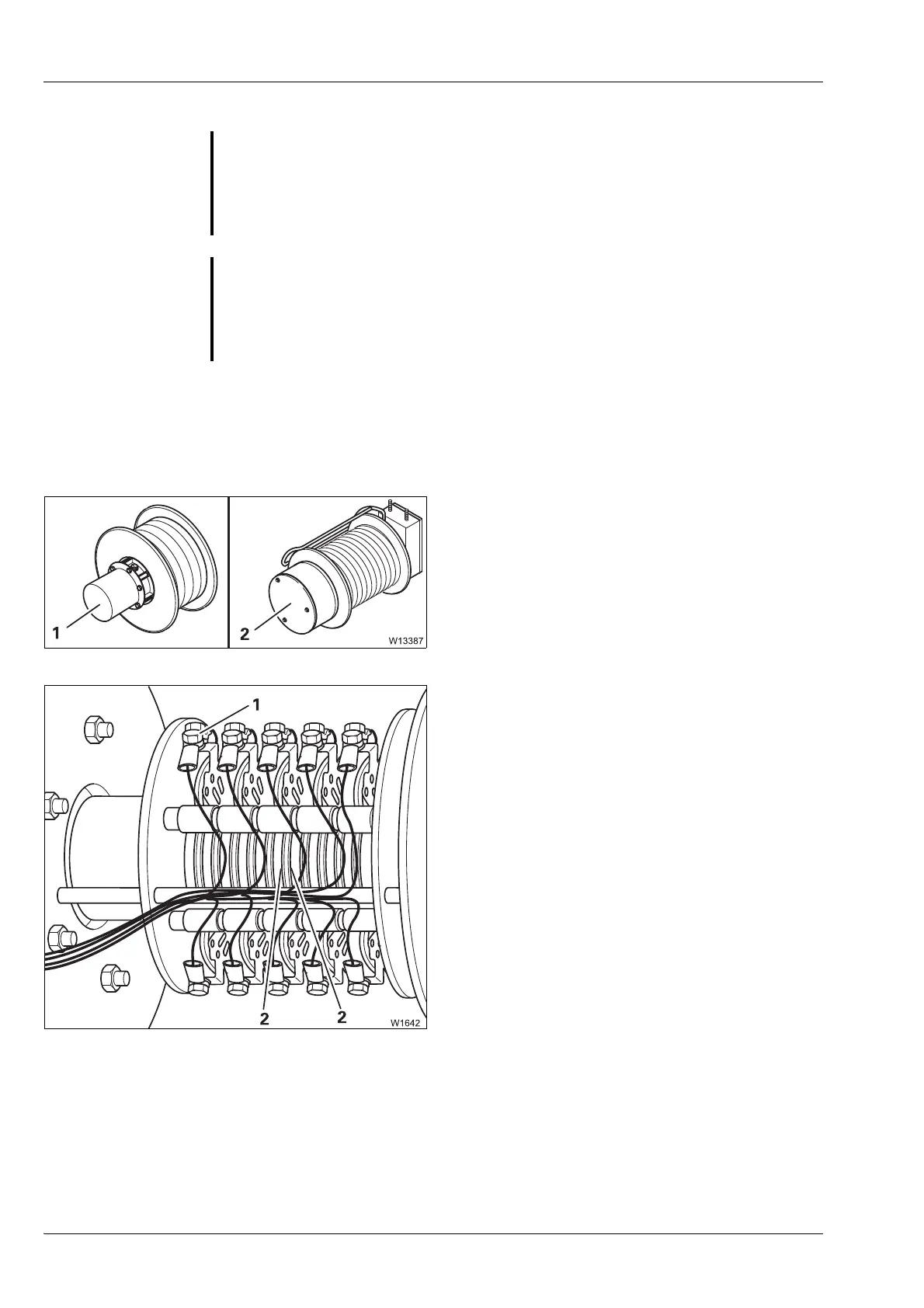

• Remove the cover (1) or (2).

• Clean and dry the cover.

• Replace the gasket if necessary.

• Only use a cloth and compressed air to

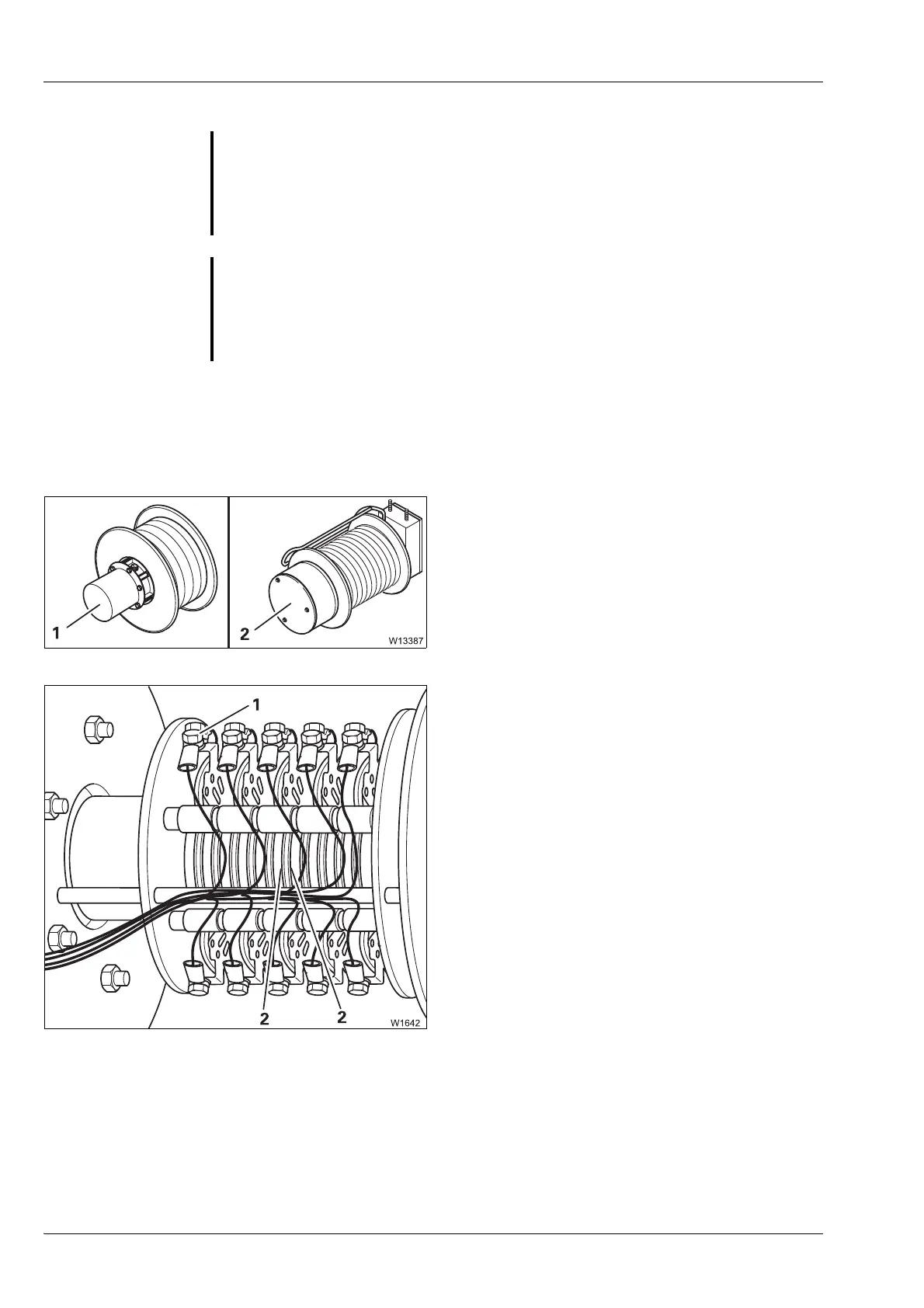

remove any dirt on the slip rings (2).

• Do not use spray oil.

• Check to make sure all screws (1) are tight.

• Attach the cover to the cable drum.

S

Risk of damage to the RCL.

Before maintenance work on the slip ring assemblies, always switch off the

battery master switch so t

hat the cable drum is without power.

This prevents short circuits which may lead to damage to the rated capacity

limiter (RCL).

G

Risk of crushing from movement of the main boom.

Only perform maintenance work when the main boom is resting in the

support and the truck crane is not running. Always ensure that the truck

crane is protected from unauthorised use before beginning maintenance

work. Remove the keys from the crane cab and put up warning signs.

Loading...

Loading...