Maintenance work on the carrier

7.14 Hydraulic system

7 - 82 3 302 719 en Maintenance manual

GMK6300L-1

13.02.2018

7.14.2 Checking the hydraulic hoses

Hydraulic hoses are also subject to ageing as well as internal and

external strain.

• Check the hydraulic hoses for

– external damage (tears, abrasion, heat damage, chemical damage),

– leaks and moist areas,

– blistering or unevenness of hose casing,

– signs of ageing (porous surface, rust on hose fittings).

Hydraulic hoses should not be used for longer

than 7

2

months from date of manufacture.

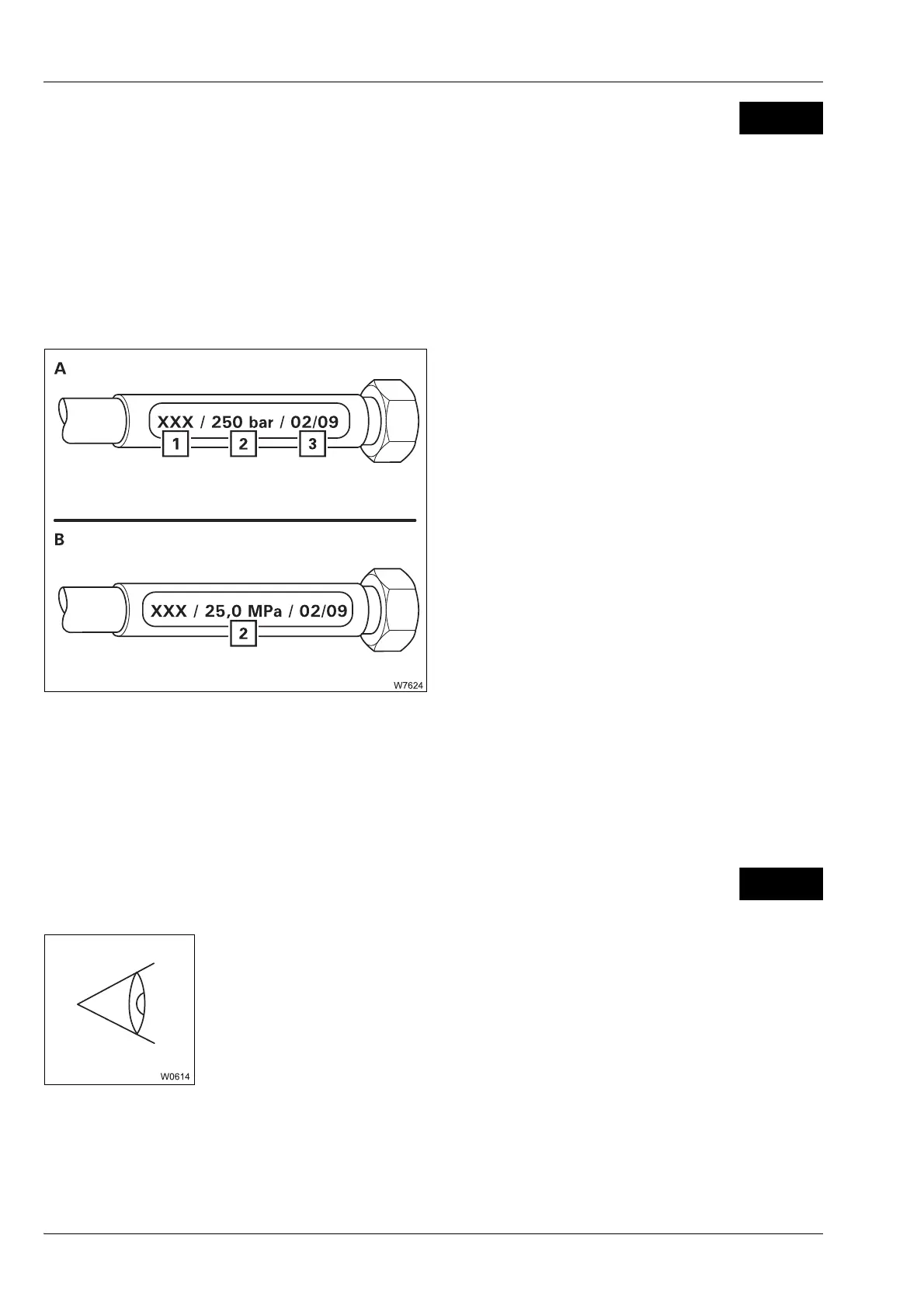

The date of manufacture and the permitted

operating pressure are marked on the hose

fitting:

• Always ensure that the corresponding parts

of the hydraulic system are depressurised.

• Damaged or old hydraulic hoses must be

replaced immediately.

7.14.3 Checking for leaks

• When the engine is running, carry out a visual inspection for leaks on the

hydraulic system (pumps, drives, cylinders, control blocks, valves, pipe

and hose lines and connections).

• Check the hydraulic oil cooler for dirt; à Have the radiator checked/cleaned,

p. 7 - 17.

• Check the oil level if there are leaks; à Checking the oil level, p. 7 - 81.

1 Manufacturer's designation.

2 Maximum operation pressure and

unit of measurement (A) (e.g. 250 bar

(3,626 psi)).

Maximum operation pressure and

unit of measurement (B) (e.g. 25.0 MPa

(3,626 psi)).

3 Month and year of manufacture.

Loading...

Loading...