Maintenance work on the superstructure

8.5 Exhaust system with exhaust emission control

13.02.2018

Maintenance manual 3 302 719 en 8 - 39

GMK6300L-1

8.5.4 Having the AdBlue system checked

This inspection may only be performed by Manitowoc Crane Care or

an authorised GROVE dealer or an authorised specialist workshop.

• Have the entire AdBlue system checked for leaks and correct operation;

Overview, p. 8 - 35.

• Also observe the information on the components mounted on the engine;

à Engine manufacturer’s documentation:

– AdBlue dosing unit,

– Solenoid valve for engine coolant for preheating the AdBlue tank.

Maintenance interval for the pump unit

The engine manufacturer specifies additional maintenance intervals for

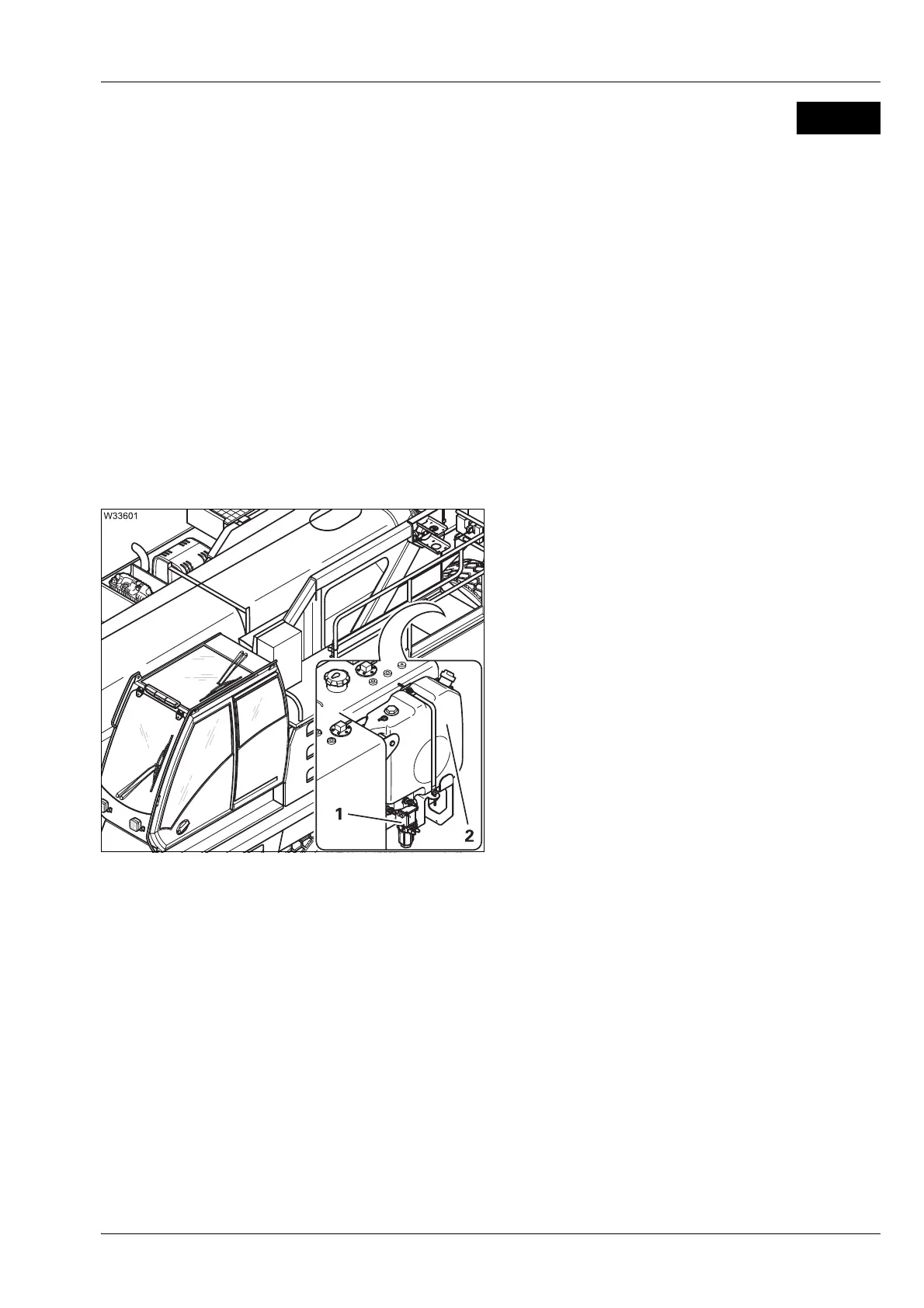

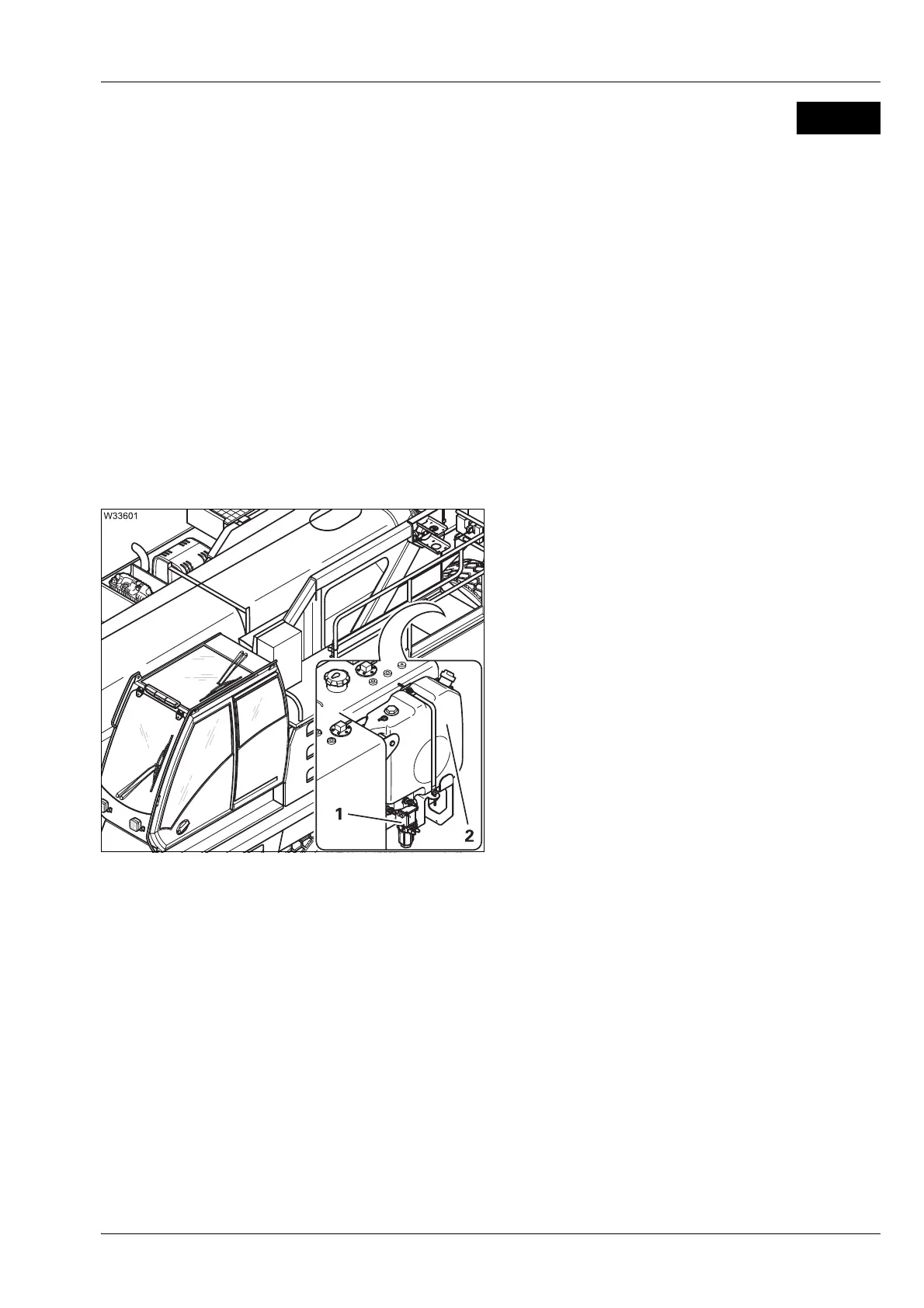

the pump unit (1);

à Engine manufacturer’s documentation.

AdBlue filter

• Have the AdBlue filter in the pump unit (1)

changed:

– for the first time after one year (M 12),

– after that, every two years (Y 2).

Pressure accumulator

• Have the pressure accumulator in the pump

unit (1) filled:

– for the first time after one year (M 12),

– after that, every two years (Y 2).

• Have the insulation hood (2) checked for damage and for tight fitting on

the AdBlue tank. The insulation hood prevents the AdBlue tank freezing

up.

• Have the electrically heated AdBlue cables at the pump unit (1) checked

for correct operation.

Loading...

Loading...