Maintenance work on the superstructure

8.8 Slewing bearing

8 - 54 3 302 719 en Maintenance manual

GMK6300L-1

13.02.2018

Safety

Instructions

Access to the

outer ring

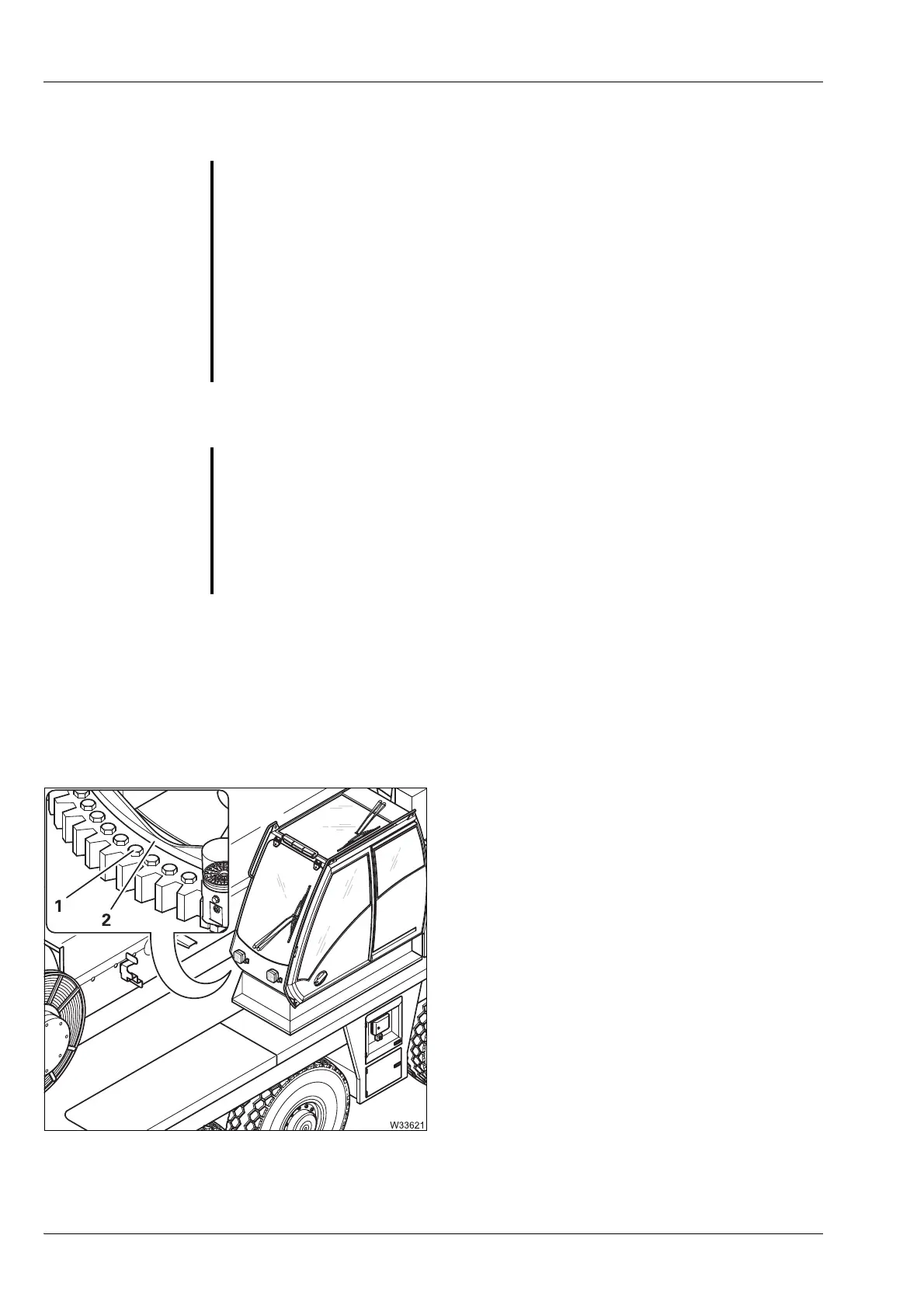

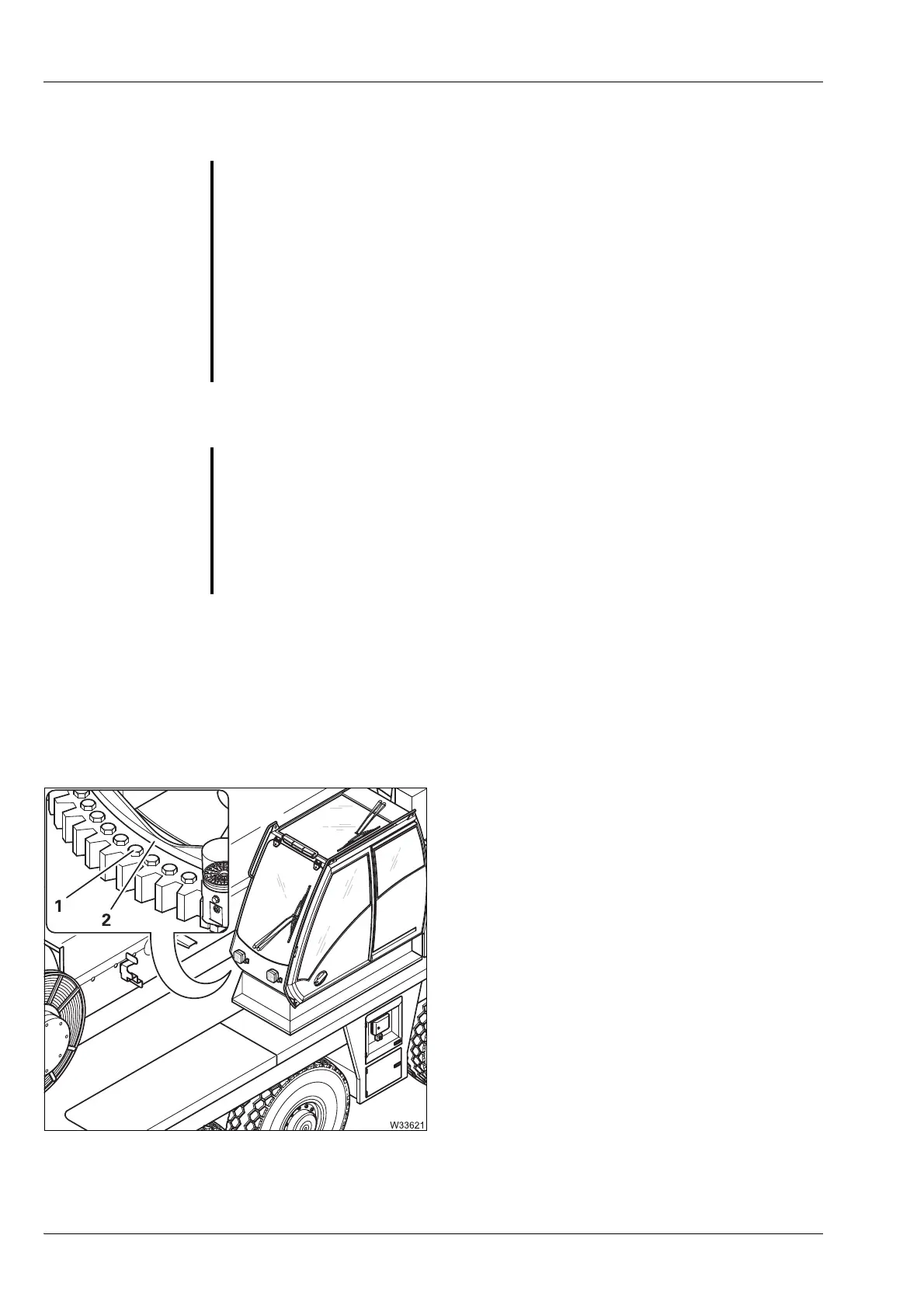

The outer ring is attached to the carrier by the

bolts (1).

• Check all 88 bolts (1) from above.

To do this, you must move the clear area (2)

on the turntable round step by step to allow

all the bolts (1) to be checked.

S

Risk of damage to the screws on the slewing bearing.

All screws were tightened at the factory with a certain torque, and this

should be checked during maintenance. Only slight tightening of the

screws is permissible, if required.

You may not slacken the screws and re-tighten them, or completely

unscrew and then reuse them.

If the superstructure has to be removed from the carrier, only a completely

new set of screws may be used to reinstall the superstructure. Only original

screws should be used, which were manufactured according to the factory

specifications.

G

Danger of the slewing bearing being ripped off.

If while checking you notice very loose, broken or missing screws, then the

slewing bearing

has been overloaded and is no longer safe to use. During

crane operation, the slewing bearing may rip off suddenly and thus cause

fatal accidents.

Do not put the truck crane back into operation and have the slewing bearing

repaired by

Manitowoc Crane Care.

Loading...

Loading...