In the first 1000 kilometers (5 months) and every

4000 kilometers (20 months) thereafter, inspections

should be carried out.

Clean and lubricate every 1000 kilometers.

Visually inspect the drive chain to see if it has the

following damages.

Check item:

1. Loosened pins

2. Roller damage

3. Chain link corrosion

4. Twisted or seized link

5. Over worn

6. Knotted or bent link

If a defect is found, the drive chain must be

replaced.

Note:

Standard transmission chain is: 428H or 428UO.

Our company recommends using this standard

transmission drive chain as a replacement part.

Inspect and adjust

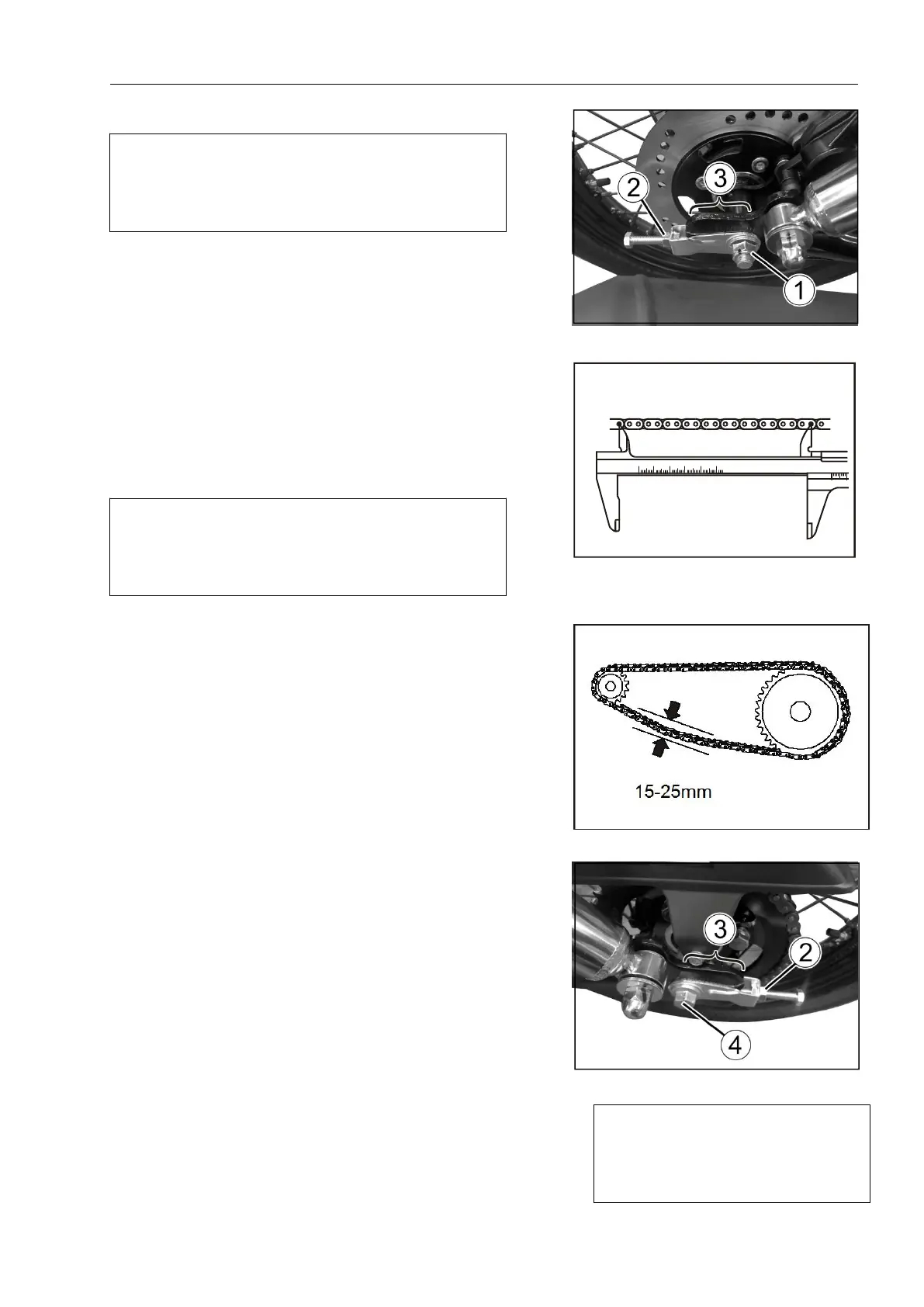

Loosen the nut ④ and the rear axle ①.

Turn the chain adjuster nut ② to fully tension the

drive chain. As shown in Fig. 2.2.23

Count the 21 pins (20 links) on the chain and measure the

distance between the two points.If the distance exceeds the

use limit, the chain must be replaced.

Chain 20 links:259mm As in Fig.2.2.24

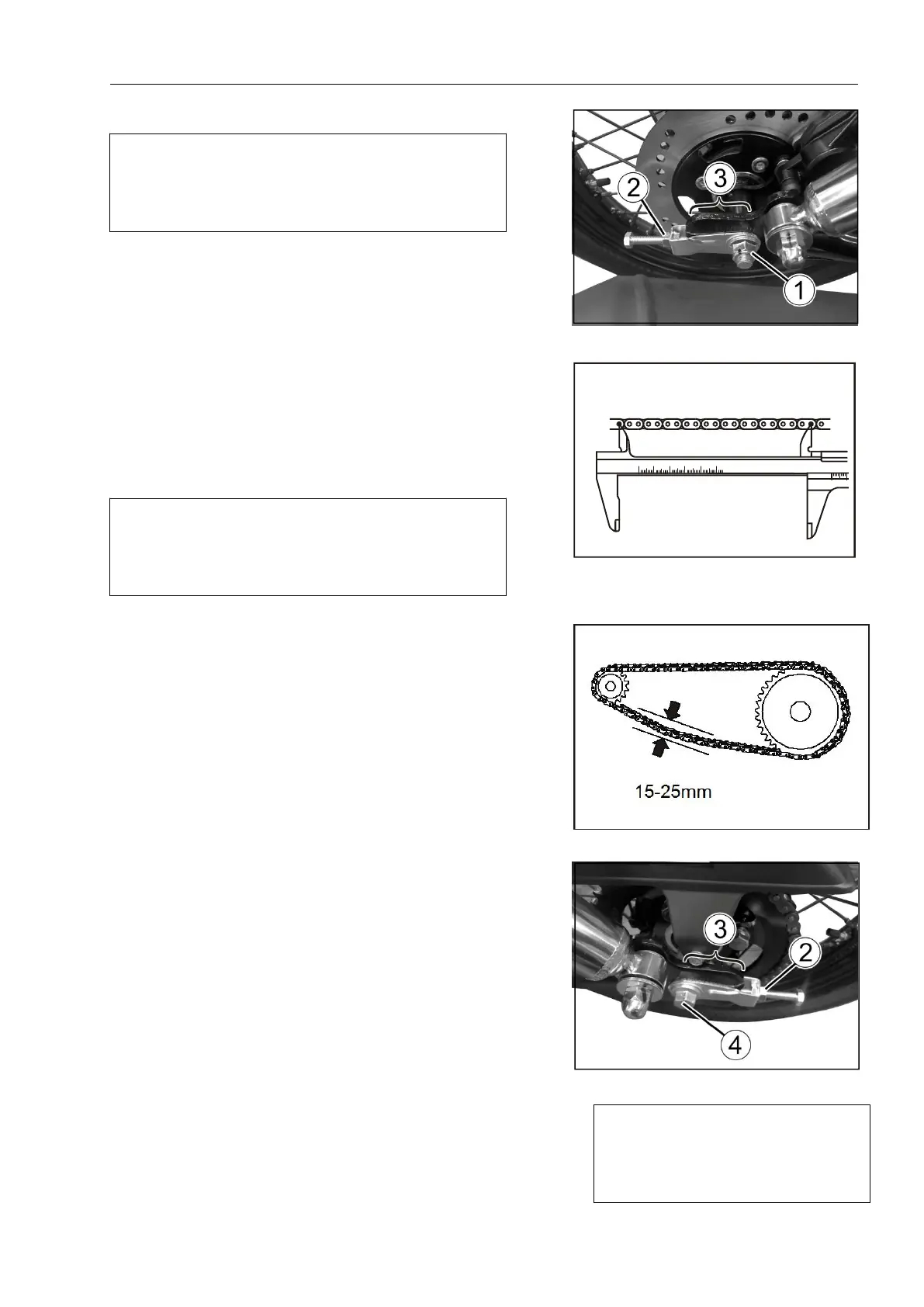

Support the motorcycle well with the side bracket.

Loosen the two chain adjuster nuts ② until the chain

slack in the center of the chain between the engine and the

rear sprocket is 15-25 mm, as shown in the figure.

The reference mark ③ must be at the same position on

the scale and the left and right scales must be at the same

scale position to ensure that the front and rear wheels can

be aligned correctly

Chain tightness:15-25mm As in Fig.2.2.25.

After adjusting the chain, tighten the rear axle nut

④.Fig.2.2.26

Rear axle nut: 78N.m(7.8kg.m)

After tightening the rear axle nut ④, recheck the

tightness of the chain, and readjust if necessary.

Tighten the two-chain adjuster nut firmly ②.

Loading...

Loading...