Chapter 3 Engine Section 2 Engine Disassemble and Re-assemble

3—8

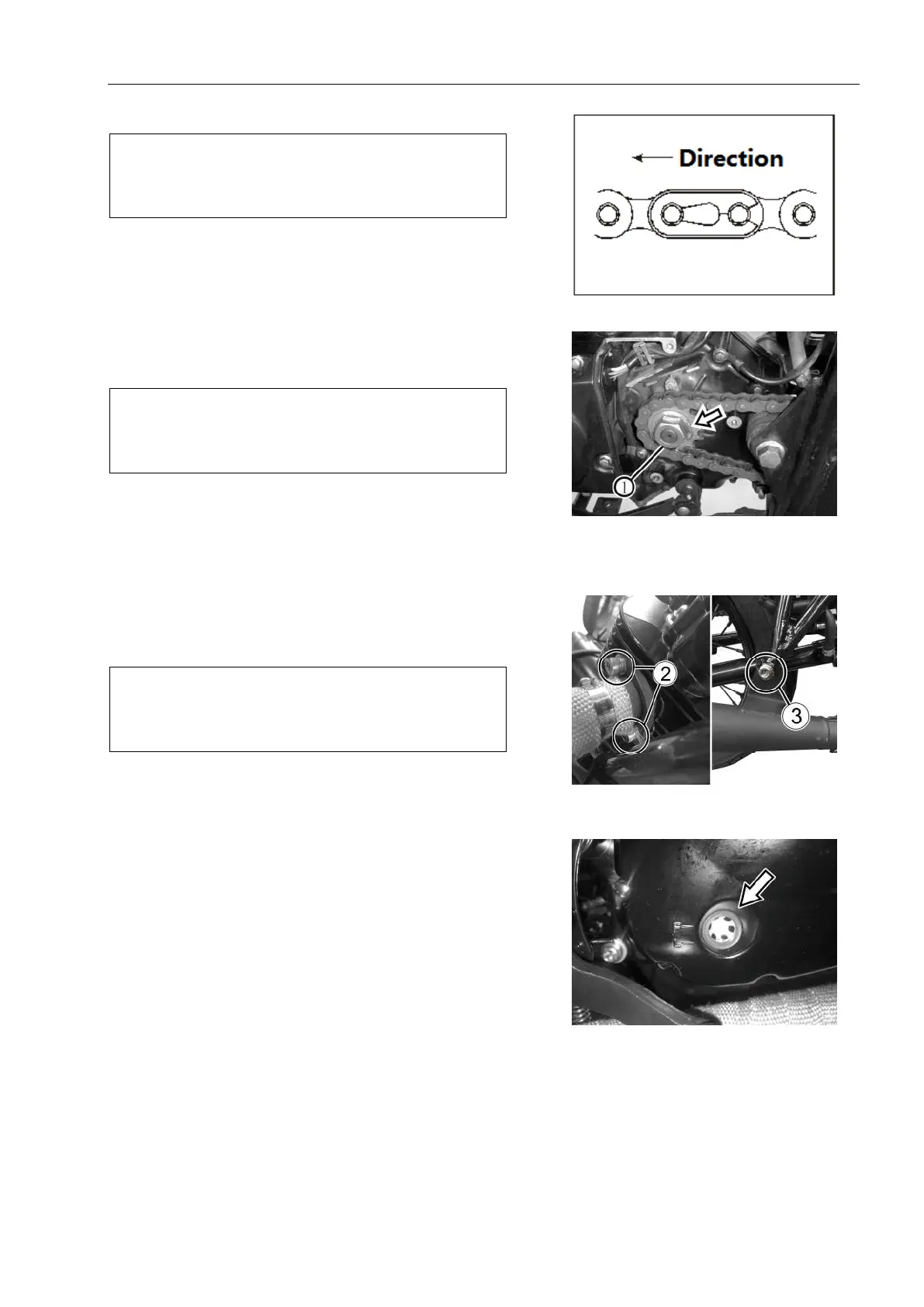

Install the chain.

Note:

The chain buckle should be assembled with the

open end in the opposite direction to the running.

As in Fig.3.2.27

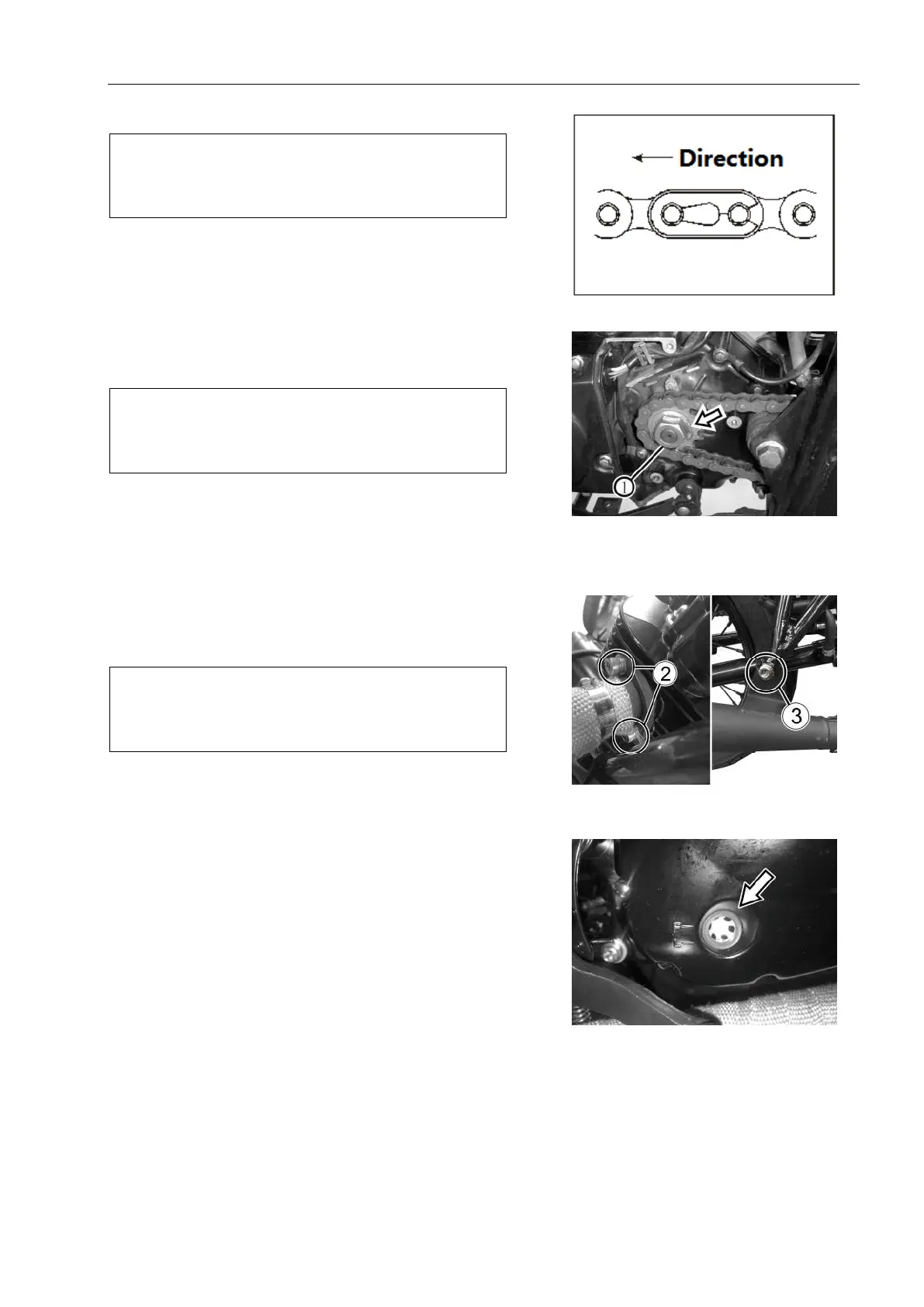

Tighten the engine sprocket nut to the specified torque.①

As in Fig.3.2.28

Engine sprocket nut:90N.m(9.0kg.m)

Note:

Press back brake pedal while tightening engine

sprocket nut.

Place the gasket firmly.

Tighten the exhaust pipe bolt and the ② Muffler mounting

bolt and to the specified torque. As in Fig. 3.2.2③ ④ 9.

Exhaust pipe bolt:11N.m(1.1kg.m)

Muffler mounting bolt:11N.m(1.1kg.m)

Note:

Check the wires, cables and hose routes.

After reassembling the engine, the following items need to

be adjusted:

Unloaded engine stable speed (idling speed)

Throttle valve cable clearance

Enriched plunger cable clearance

Clutch lever clearance

Drive chain

Rear brake pedal height and free travel

After heavy maintenance, 1300 ml of SAE10/40 oil, SF or

SG grade, needs to be injected into the engine. Start the

engine and let it run at a steady speed without load for a

few minutes. Then stop the engine, wait about 1 minute,

and check the oil level. If the oil level is below the "F" line,

add oil until it reaches the "F" line.

Fig.3.2.27

Fig.3.2.28

Fig.3.2.29

Fig.3.2.30

Loading...

Loading...