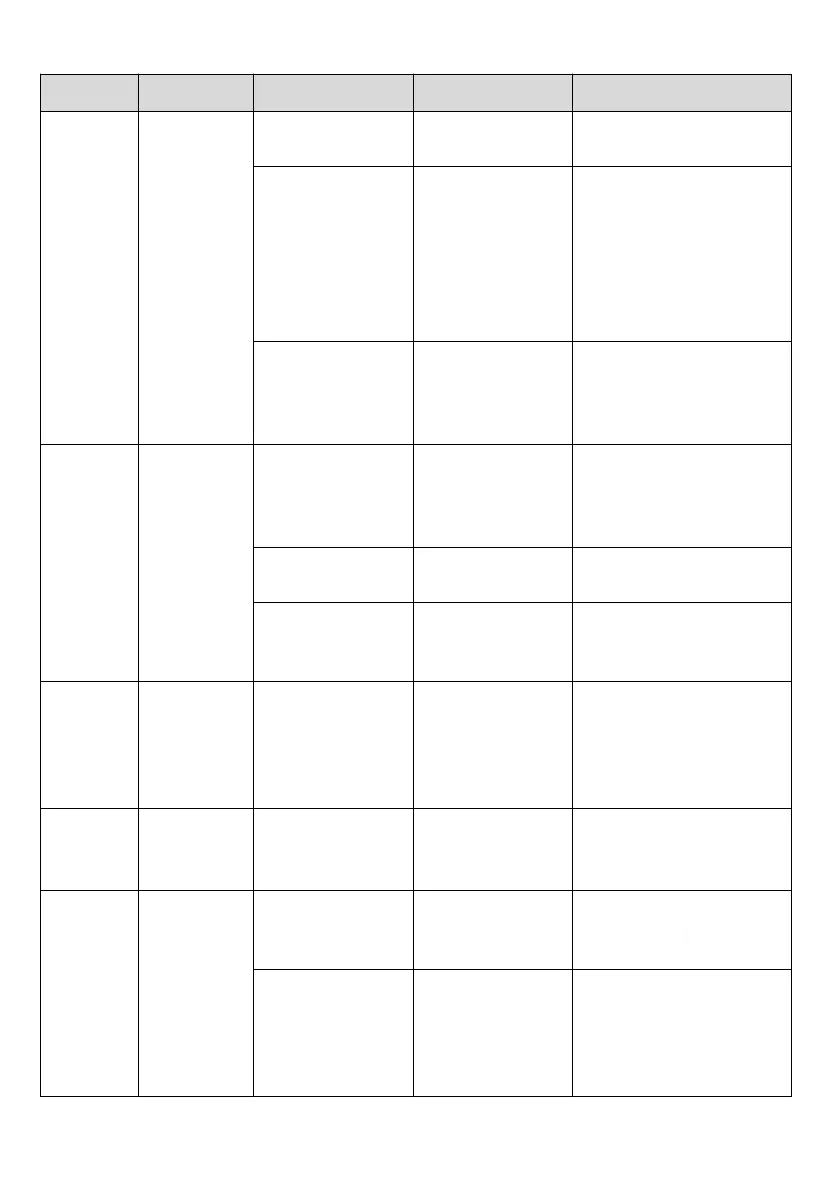

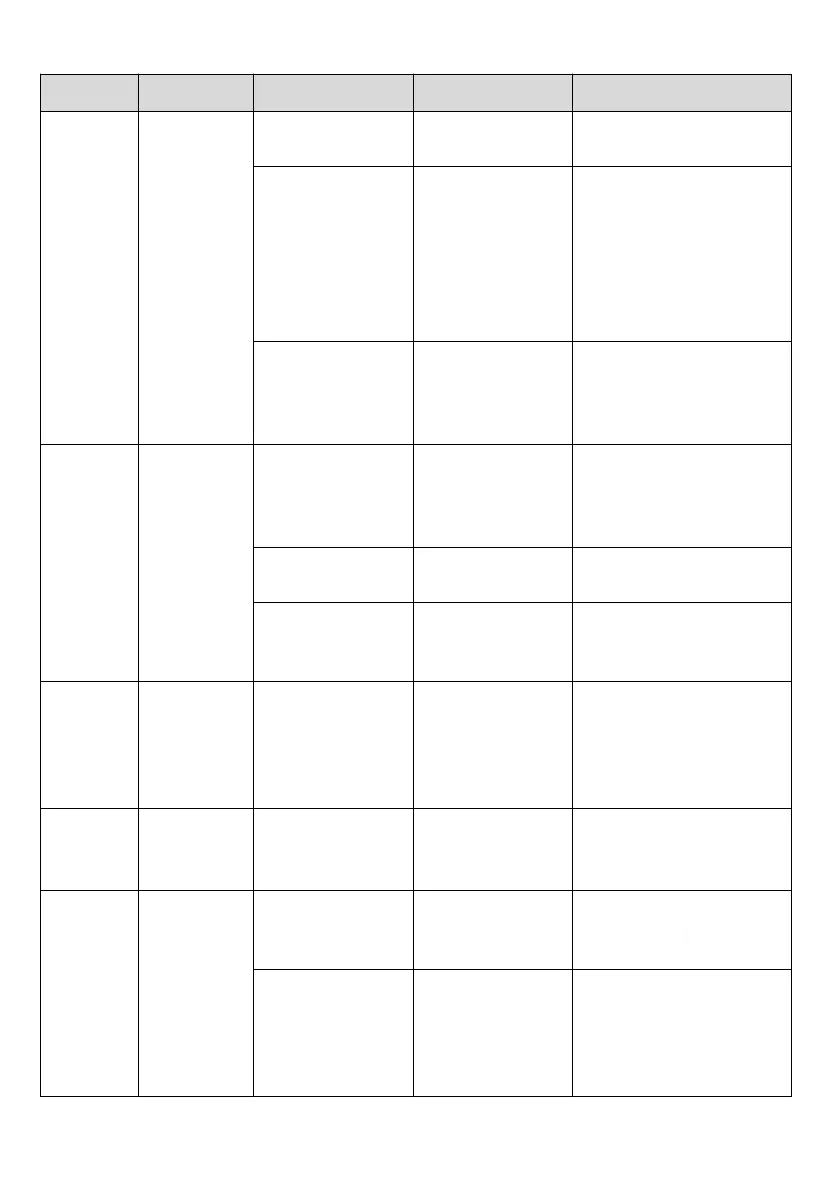

Chapter 9 Troubleshooting

The braking resistor fails.

Measure the resistance

between P and PB.

If the resistor is open, replace the

external braking resistor.

External braking resistor

value does not match

(The resistance of the

the external resistor is too

large, and the energy

absorption during braking

is insufficient.)

Confirm the braking

resistor value.

Select the appropriate braking

resistor value according to

operating conditions and load.

The motor is in abrupt

acceleration/deceleration

state.

Confirm the deceleration

ramp time during running

and monitor the DC bus

voltage P11.09.

Increase the

acceleration/deceleration time in the

allowed range.

The power output phase

(UVW) loss or incorrect

phase sequence occurs

on the servo drive.

Perform motor trial

running when the motor

has no load and check

the motor wiring.

Connect the motor cables correctly

again or replace them.

Connect the motor cables correctly

again or replace them.

The motor rotor is locked

due to mechanical

factors.

Confirm the running

command and motor

speed.

Eliminate mechanical factors.

There is phase loss in

input L1, L2, L3.

Check input wiring; check

input power.

If the input power is single-phase

220V, then P10.00=1; if the input

power is three-phase 220V, check

whether the input power is missing

phase, and replace the cable wiring.

There is phase loss in

output U, V, W.

Check the output wiring

Check the motor and the

cables

Replace the cable wiring.

Ambient temperature is

too high

Check the cooling

conditions around the

drive.

Improve the servo drive cooling

conditions, reduce the ambient

temperature.

Multiple overload

operation

Check fault records,

whether overload fault

has been reported.

Waiting for 60s to reset after

overload, increase the drive, motor

capacity, increase the acceleration

and deceleration time, reduce the

load.

Loading...

Loading...