Chapter 6 Commissioning Instructions

For an incremental encoder, encoder resolution = encoder lines * 4, for example, the resolution of a 2500-line

incremental encoder is 2500*4=10000.

b. Electronic gear ratio switching setting

When P05.05 is 0, the electronic gear ratio switching function can be used. It should be determined whether it is

necessary to switch among 4 sets of electronic gear ratios according to the mechanical operation, and the

electronic gear ratio switching conditions should be set. There is one and only one set of electronic gear ratios

active at any one time.

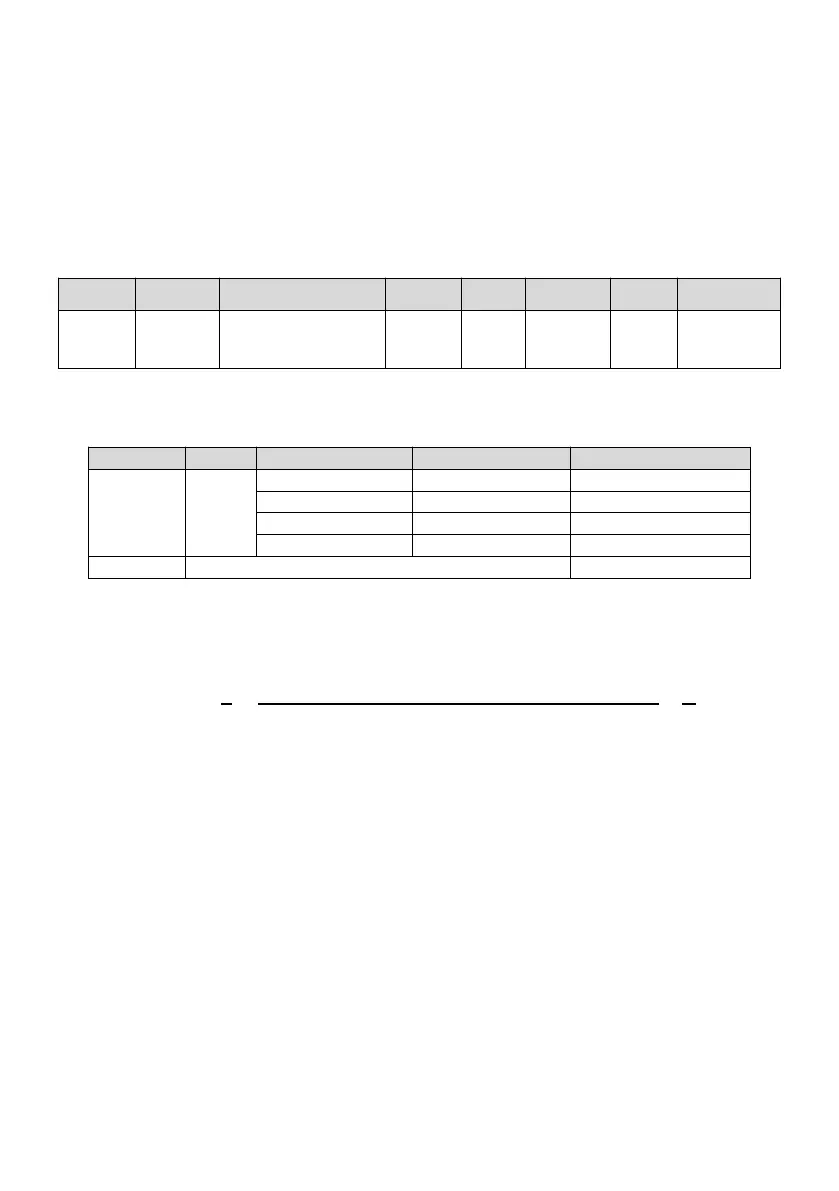

Associated function code

Electronic

gear ratio

switching

conditions

0: Position command is 0,

switch after 3ms duration

1: Real-time switching

Set electronic

gear ratio

switching

conditions

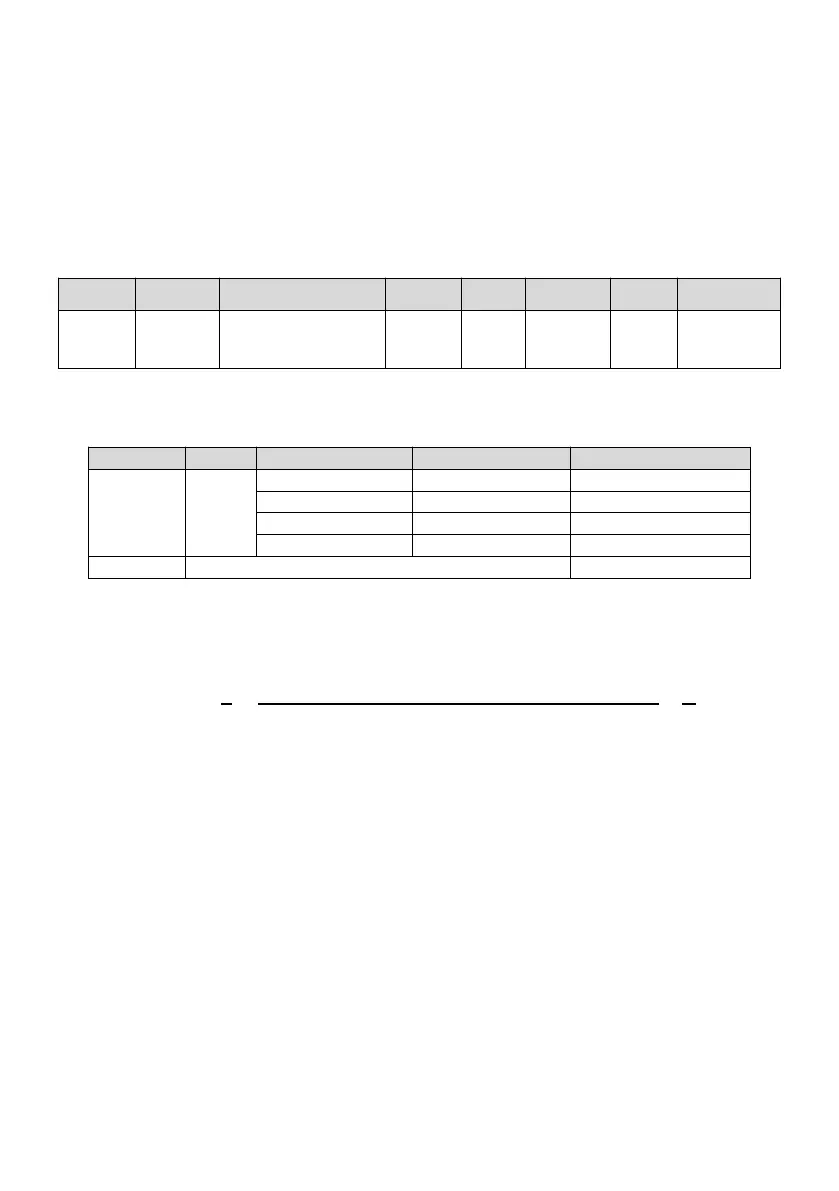

At the same time, please configure the 2 DI terminals of the servo drive as functions 15 and 16 (FunIN.15 and

FunIN.16), and determine the valid logic of the DI terminals. Refer to the table below for electronic gear ratio

selection. When no DI is configured as FunIN.15 or FunIN.16, FunIN.15 and FunIN.16 are invalid by default.

Electronic gear ratio B/A

Encoder resolution/P05.05

3) Calculation method of electronic gear ratio:

When the machine reduction ratio between the motor shaft and the load side is m/n (when the motor rotates m

circle, the load shaft rotates n circle), the set value of the electronic gear ratio can be obtained by the following

formula.

Electronic gear ratio

B

A

=

Encoderresolution

thedisplacementforloadshaftrotateacircle (commandunit)

×

m

n

a. Confirm the mechanical parameters and servo motor encoder resolution

Confirm mechanical parameters, such as reduction ratio, ball screw lead, belt transmission ratio, confirm the

servo motor encoder resolution.

b. Confirm the positioning accuracy (i.e. pulse equivalent)

Pulse equivalent refers to the load minimum movement unit corresponding to each pulse command signal. Pulse

equivalent can be 0.001mm, 0.1 °, 0.01 inches, a pulse is entered, moving a pulse equivalent of the distance or

angle.

For example, pulse equivalent is 0.001mm, when the input command pulse is 50000, the amount of the load

movement is (50000 * 0.001mm) = 50mm.

c. Calculate the number of position command required by load shaft rotate a circle

Use mechanical parameters, pulse equivalent, calculate the number of position command required by load shaft

rotate a circle.

For example, the ball screw pitch is 5mm, pulse equivalent is 0.001mm, then:

The displacement for load shaft rotate a circle (command bits) = 5mm / 0.001mm = 5000

Loading...

Loading...