EDI DIAGNOSIS

SERVICE MANUAL NUMBER 22

90-860074--1 FEBRUARY 2002 Page 5E-89

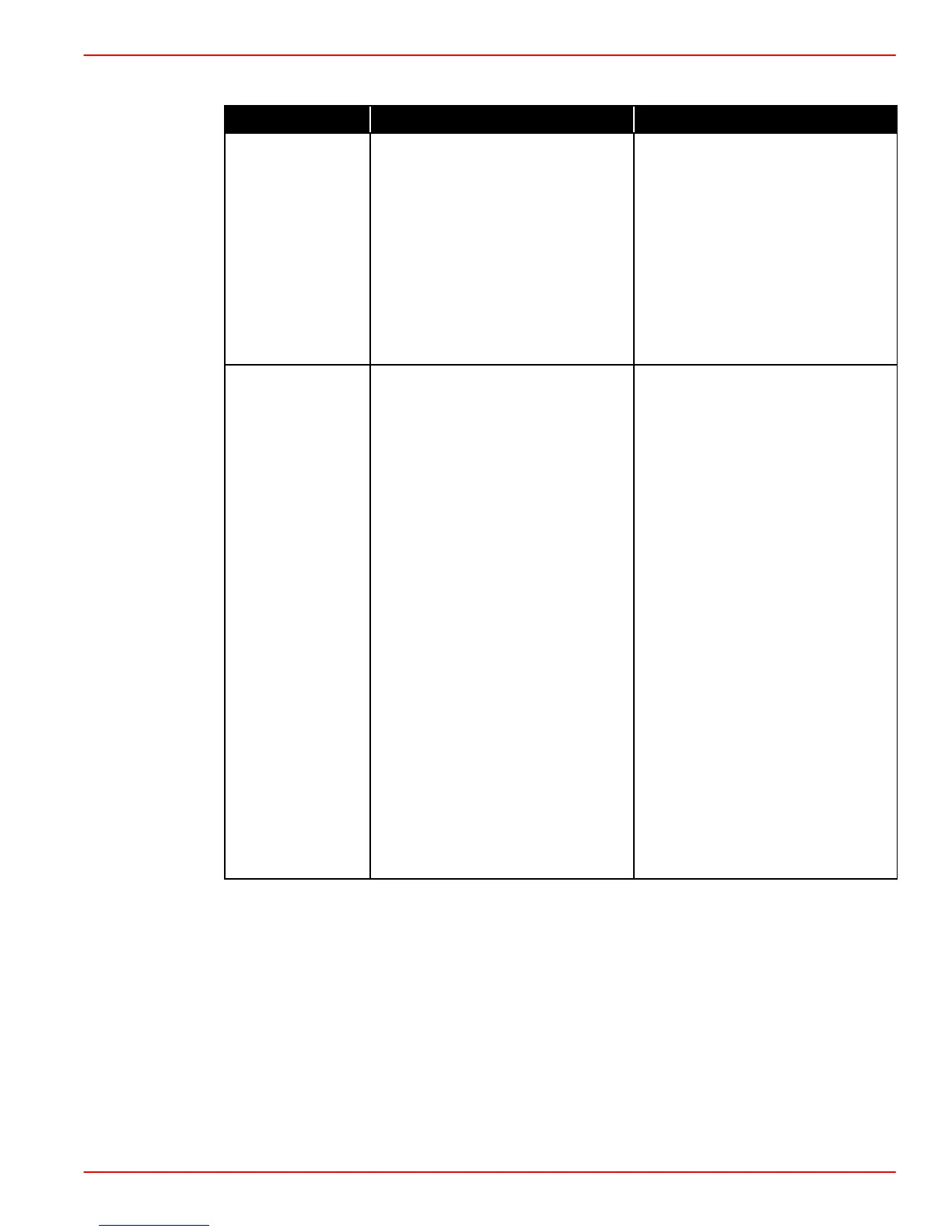

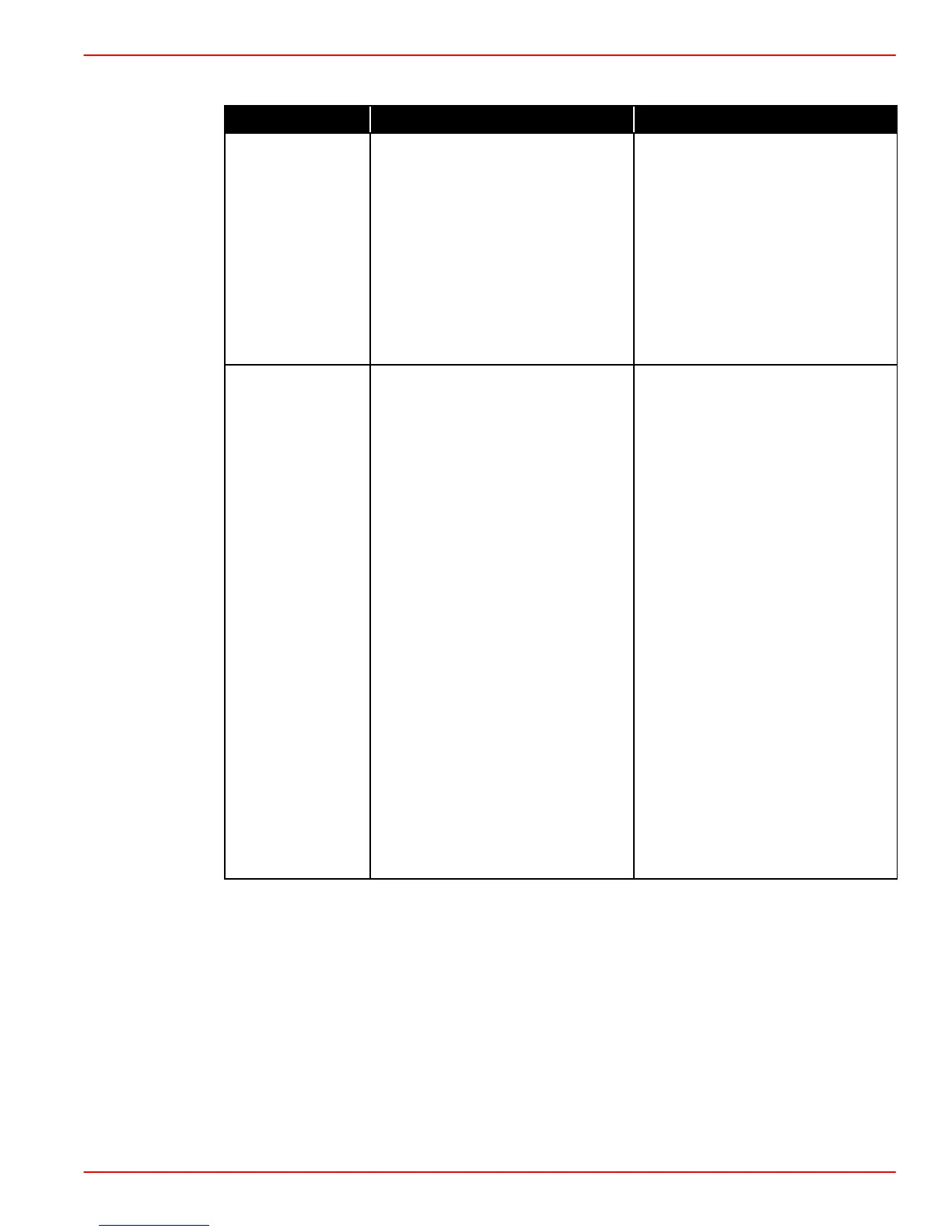

Troubleshooting Charts (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

LUBRICATING

OIL PRESSURE

TOO HIGH

1. Pressure switch/gauge not

operating properly.

2. Engine operating too cold.

3. Oil viscosity too thick.

4. Oil pressure relief valve stuck

closed or binding.

1. Verify the pressure switch is

functioning correctly. If not,

replace switch/gauge.

2. Refer to “Coolant

Temperature Below Normal.”

3. Make sure the Correct oil

being used, (Refer to Group,

Lubrication and

Maintenance).

4. Check and replace valve.

LUBRICATING

OIL LOSS

1. External leaks.

2. Crankcase being overfilled.

3. Incorrect oil specification or

viscosity.

4. Oil Cooler leak.

5. High blow-by forcing oil out

the breather.

6. Turbocharger leaking oil to

the air intake.

7. Piston rings not sealing (oil

being consumed by the

engine).

1. Visually inspect for oil leaks.

Repair as required.

2. Verify that the correct

dipstick and/or correctly

marked dipstick is being

used.

3. (A) Make sure the correct oil

is being used.

(B) Look for reduced

viscosity from dilution with

fuel.

(C) Review/reduce the oil

change intervals.

4. Check and replace the oil

cooler.

5. Check the breather tube area

for signs of oil loss. Perform

the required repairs.

6. Inspect intercooler for

evidence of oil transfer

Repair as required.

7. Perform compression check.

Repair as required.

Loading...

Loading...