EDI DIAGNOSIS SERVICE MANUAL NUMBER 22

Page 5E-90 90-860074--1 FEBRUARY 2002

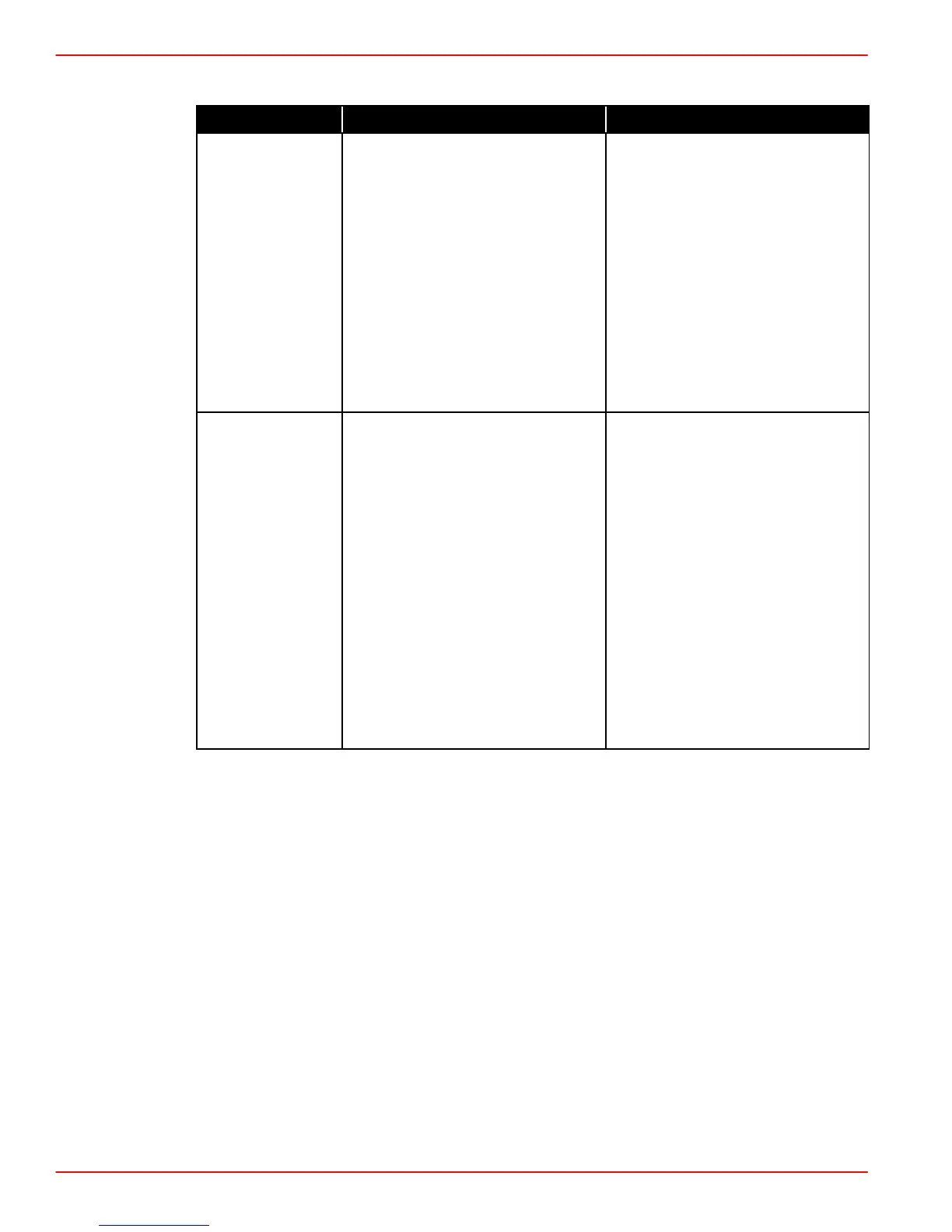

Troubleshooting Charts (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

COMPRESSION

KNOCKS

1. Air in the fuel system.

2. Poor quality fuel or

water/gasoline contaminated

fuel.

3. Engine overloaded.

4. Incorrect injection pump

timing.

5. Improperly operating

injectors.

1. Bleed the fuel system.

2. Verify by operating from a

temporary tank with good

fuel. Clean and flush the fuel

supply tanks. Replace

fuel/water separator.

3. Verify the engine load rating

is not being exceeded.

4. Scan / check injection pump

timing.

5. Check and replace

inoperative Injector.

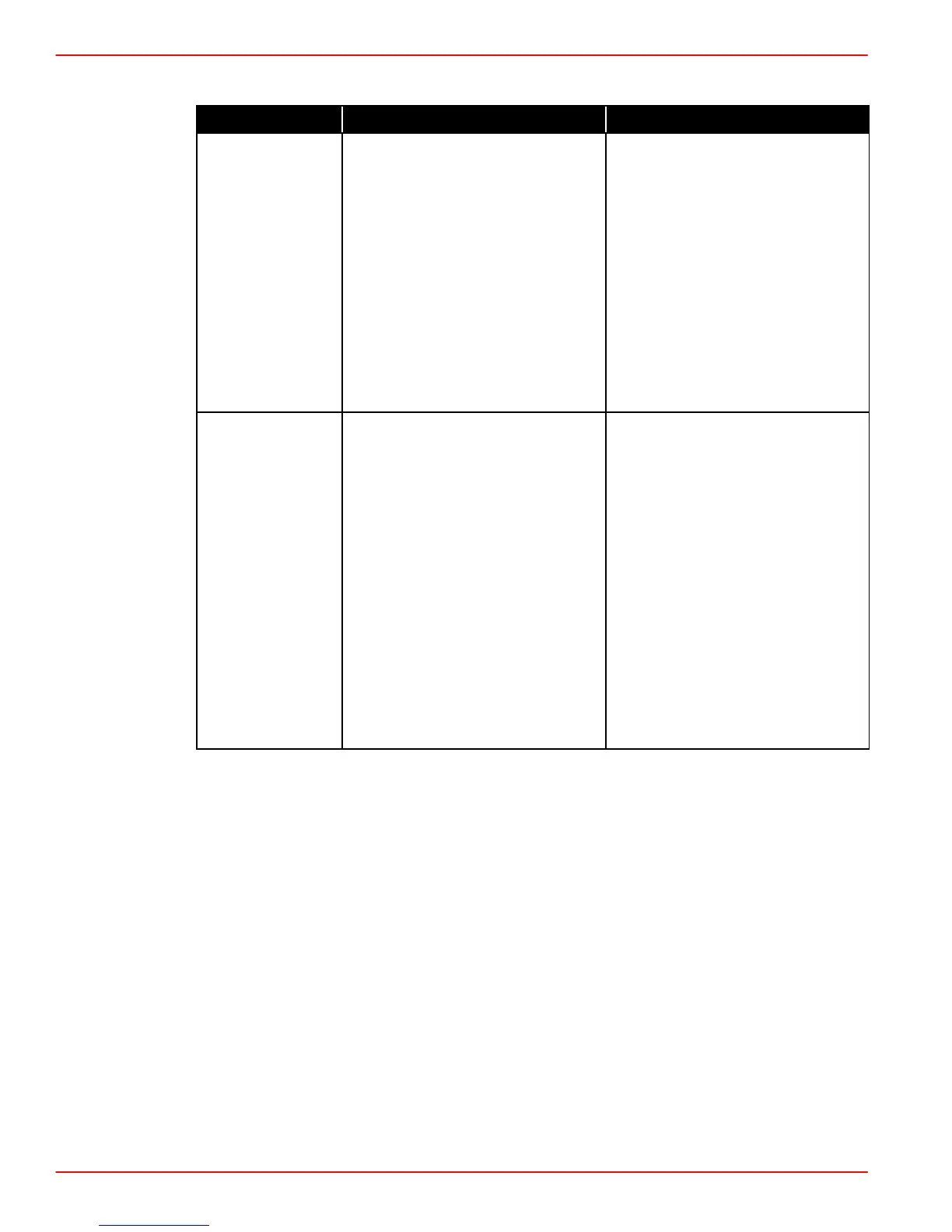

EXCESSIVE

VIBRATION

1. Loose or broken engine

mounts.

2. Damaged or improperly

operating accessories.

3. Improperly operating

vibration damper.

4. Worn or damaged alternator

bearing.

5. Flywheel housing

misaligned.

6. Loose or broken power

component.

7. Worn or unbalanced drive

line components.

1. Replace engine mounts.

2. Check and replace the

vibrating components.

3. Inspect / replace the

vibration damper.

4. Check/replace the alternator.

5. Check/correct flywheel

alignment.

6. Inspect the crankshaft and

rods for damage that causes

an unbalance. repair/replace

as required.

7. Check/repair drive line

components.

Loading...

Loading...