EDI DIAGNOSIS

SERVICE MANUAL NUMBER 22

90-860074--1 FEBRUARY 2002 Page 5E-91

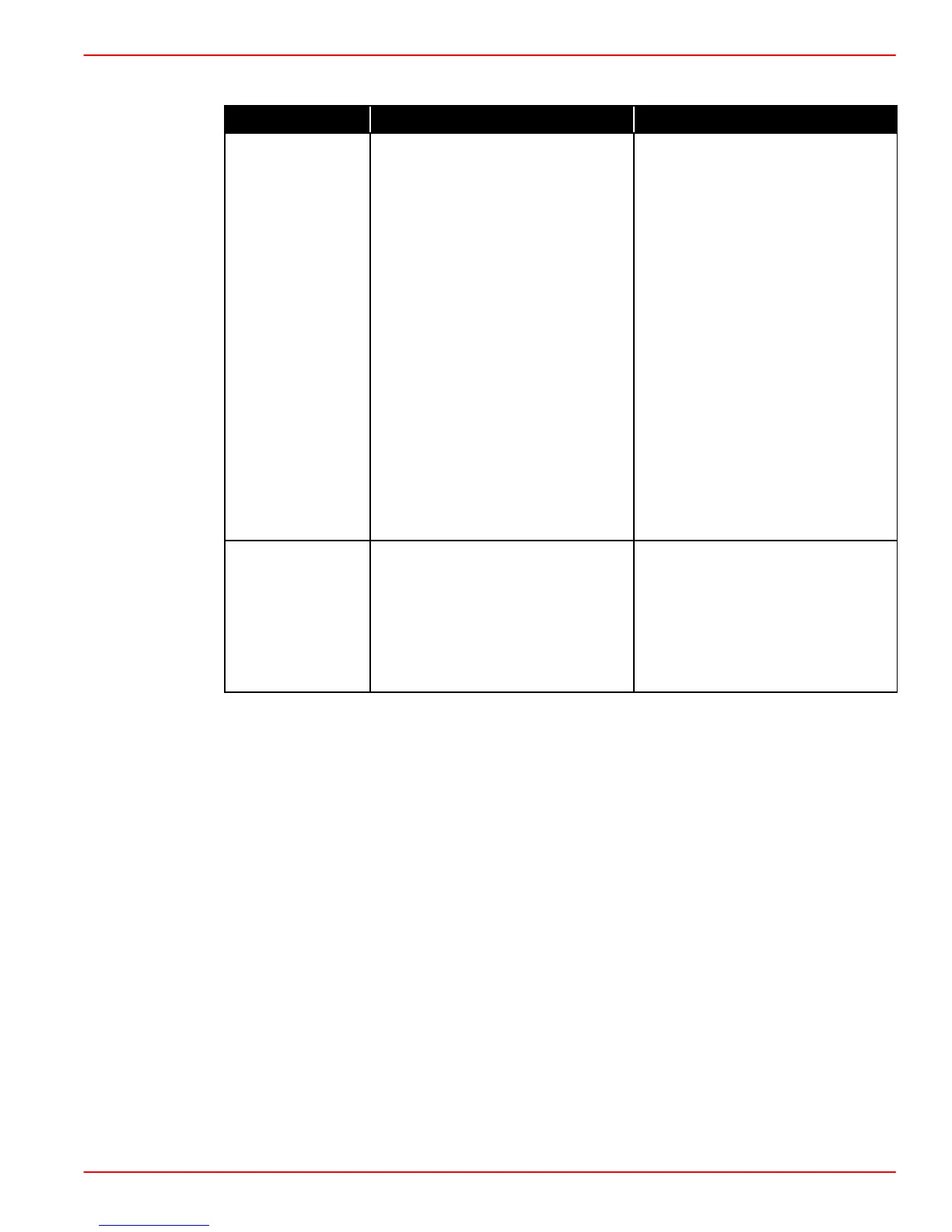

Troubleshooting Charts (Continued)

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE

ENGINE

NOISES

1. Drive belt squeal, insufficient

tension or abnormally high

loading.

2. Intake air or exhaust leaks.

3. Excessive valve lash.

4. Turbocharger noise.

5. Gear train noise.

6. Power function knock.

1. Inspect the drive belt. Check

drive belt tension.

2. Refer to Excessive Exhaust

smoke (Engine Diagnosis

Performance).

3. Make sure the push rods are

not bent and rocker levers are

not severely worn Replace

Bent or severely worn pads.

4. Check turbocharger impeller

and turbine wheel for housing

contact. Repair/replace as

required.

5. Visually inspect and measure

gear backlash. Replace gears

as required.

6. Check/replace rod and main

bearings.

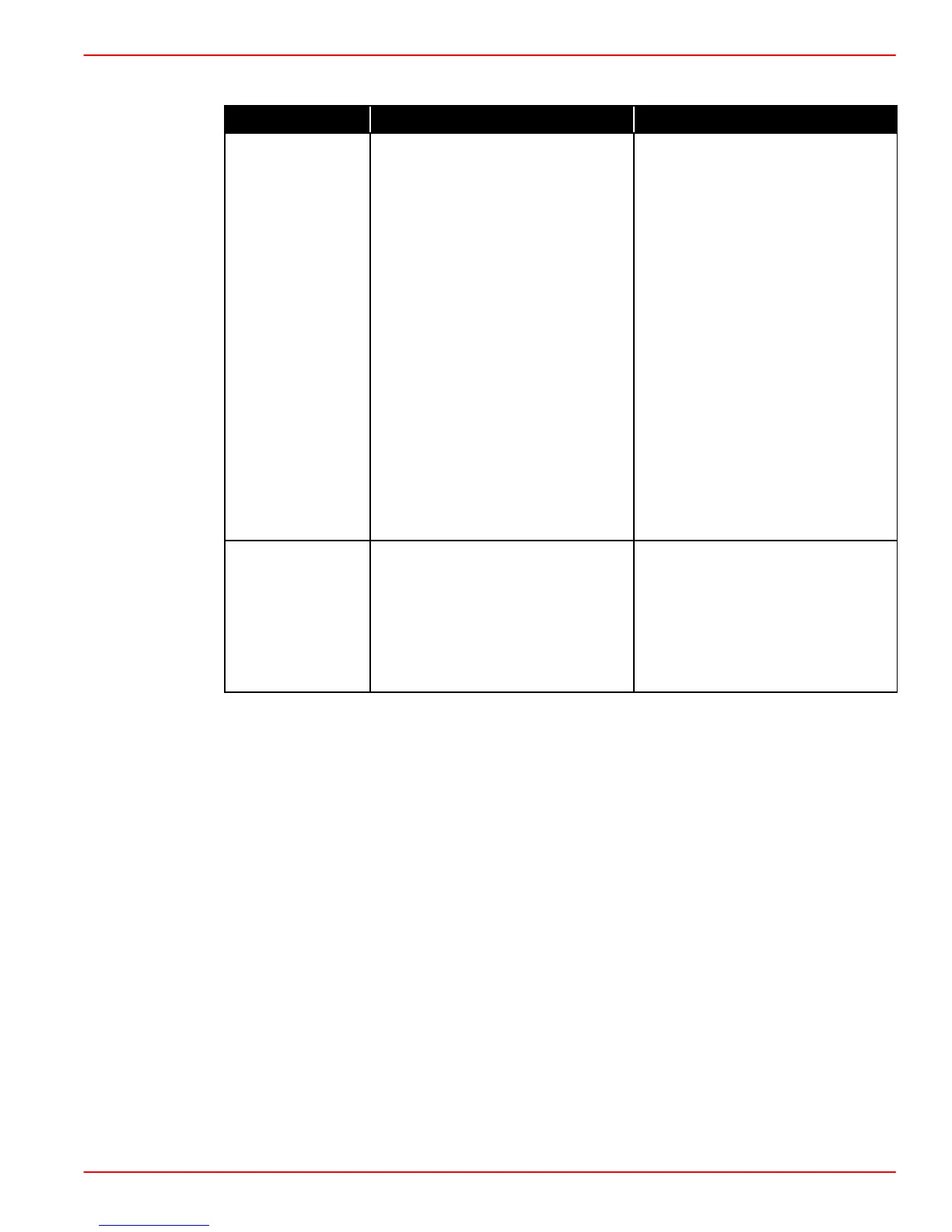

ALTERNATOR

NOT

CHARGING OR

INSUFFICIENT

CHARGING

1. Loose or corroded battery.

2. Alternator belt slipping.

3. Alternator pulley loose on

shaft.

4. Improperly operating alterna-

tor.

1. Clean/tighten battery

connection.

2. Check/replace and adjust

belt.

3. Tighten pulley.

4. Check/replace alternator.

Loading...

Loading...