3 - 85 3 - 85

MELSEC-Q

3 SPECIFICATIONS

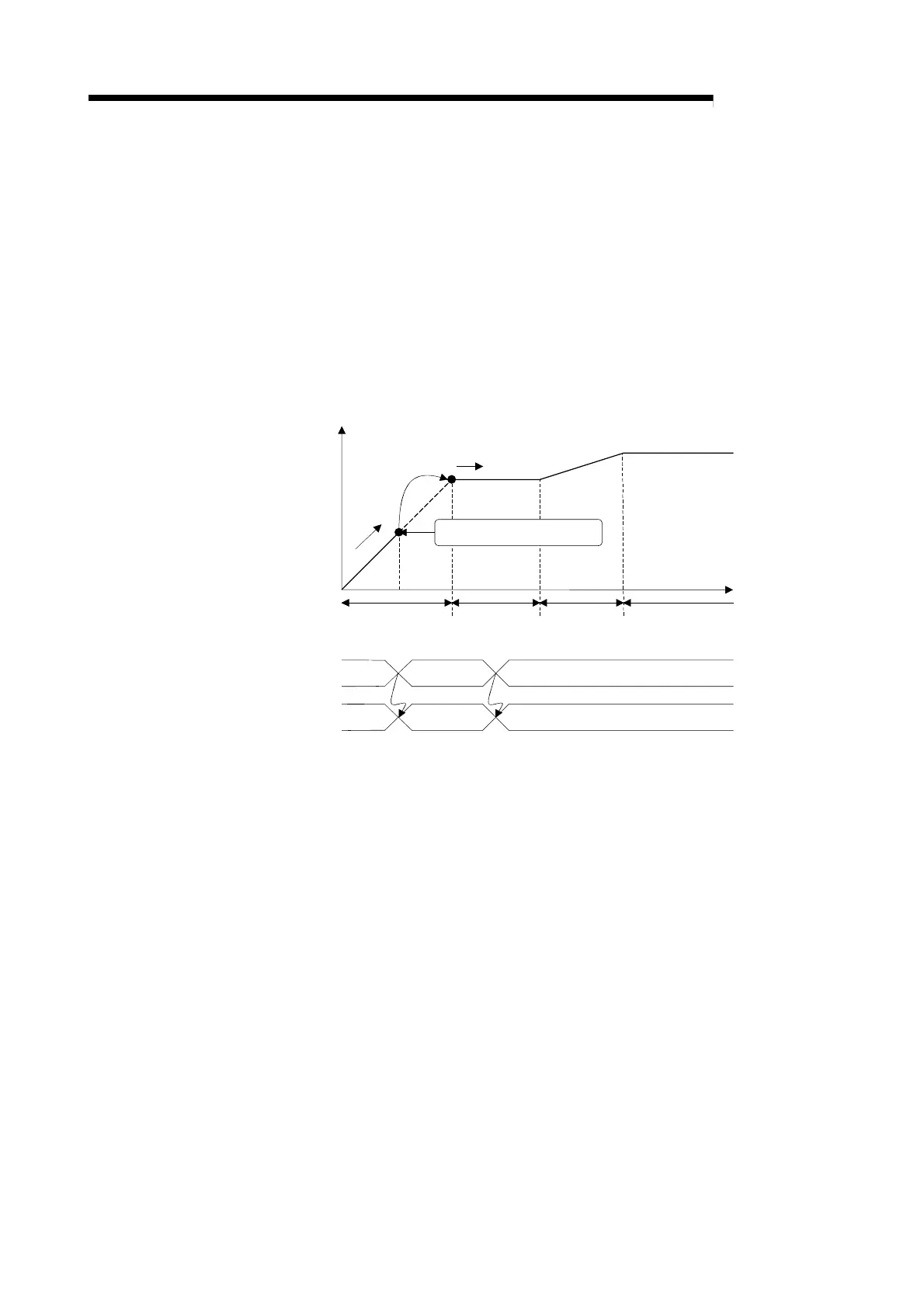

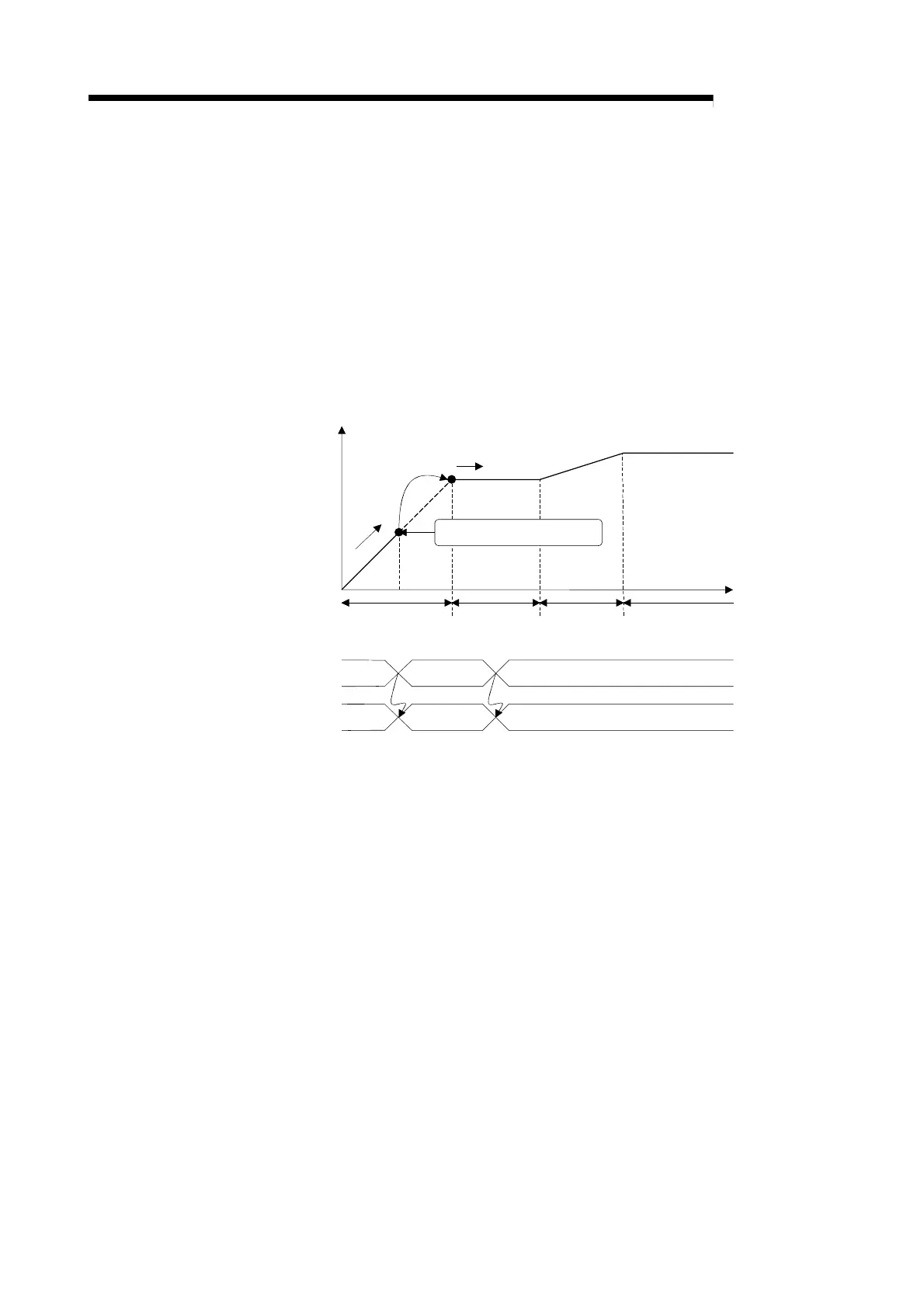

3.5.49 Command advancing (buffer memory address 202, 218: Un\G202, Un\G218)

(1) This is the command of the advancing operation to carry the progress of the

program control forward to the next segment.

• Advancing OFF : Set 0 (default value).

The advancing operation is not performed.

• Advancing ON : Set 1.

After performing the advancing operation and carrying the

progress of the program forward by one segment, this

command executes the program from the next segment.

Set value

Time

Segment 1

01 0

Command advancing

(Buffer memory address: 202, 218)

Advancing completion flag

(Buffer memory address: 263, 519)

01 0

Command advancing ON

Fast-

forward

Execute

from here

Segment 2 Segment 3 Segment 4

(2) The completion confirmation of the advancing operation is performed by the

advancing completion flag (buffer memory address: 263, 519).

(3) This command is invalid at the hold status.

3.5.50 Segment monitor (buffer memory address 256, 512: Un\G256, Un\G512)

(1) The currently operated segment No. is stored.

The stored values are 1 to 16.

3.5.51 Segment remaining time (buffer memory address 257, 513: Un\G257, Un\G513)

(1) The remaining time of the currently operated segment is stored.

(2) The time scale of the segment remaining time is the scale set by the time scale

(buffer memory address: 274, 530). (Refer to Section 3.5.62)

Loading...

Loading...