3 - 62 3 - 62

MELSEC-Q

3 SPECIFICATIONS

3.5.6 Approach flag (buffer memory address 17, 18: Un\G17, Un\G18)

(1) This flag checks if the measured value (PV) is within approach band.

(2) When the measured value (PV) is within approach band, the flag is "1".

Also, when the soak time (buffer memory address: 168) is set and the

measured value (PV) stays within approach band in the set time only, the flag is

"1".

3.5.7 Set value (SV value) monitor (buffer memory address 25, 26: Un\G25, Un\G26)

(1) The current value of set value monitor is stored.

The transitional change of set value during the program control is monitored

when setting the setting change rate limiter (buffer memory address: 52, 84).

3.5.8 Cold junction temperature measured value (buffer memory address 29: Un\G29)

(1) The measured temperature of cold junction temperature compensation resistor

mounted on Q62HLC is stored.

The value to be stored is in the range of –10 to 100 (-10 to 100

).

3.5.9 Control mode monitor (buffer memory address 30: Un\G30)

(1) When control mode, the switching value of control mode is stored after the

completion of shifting.

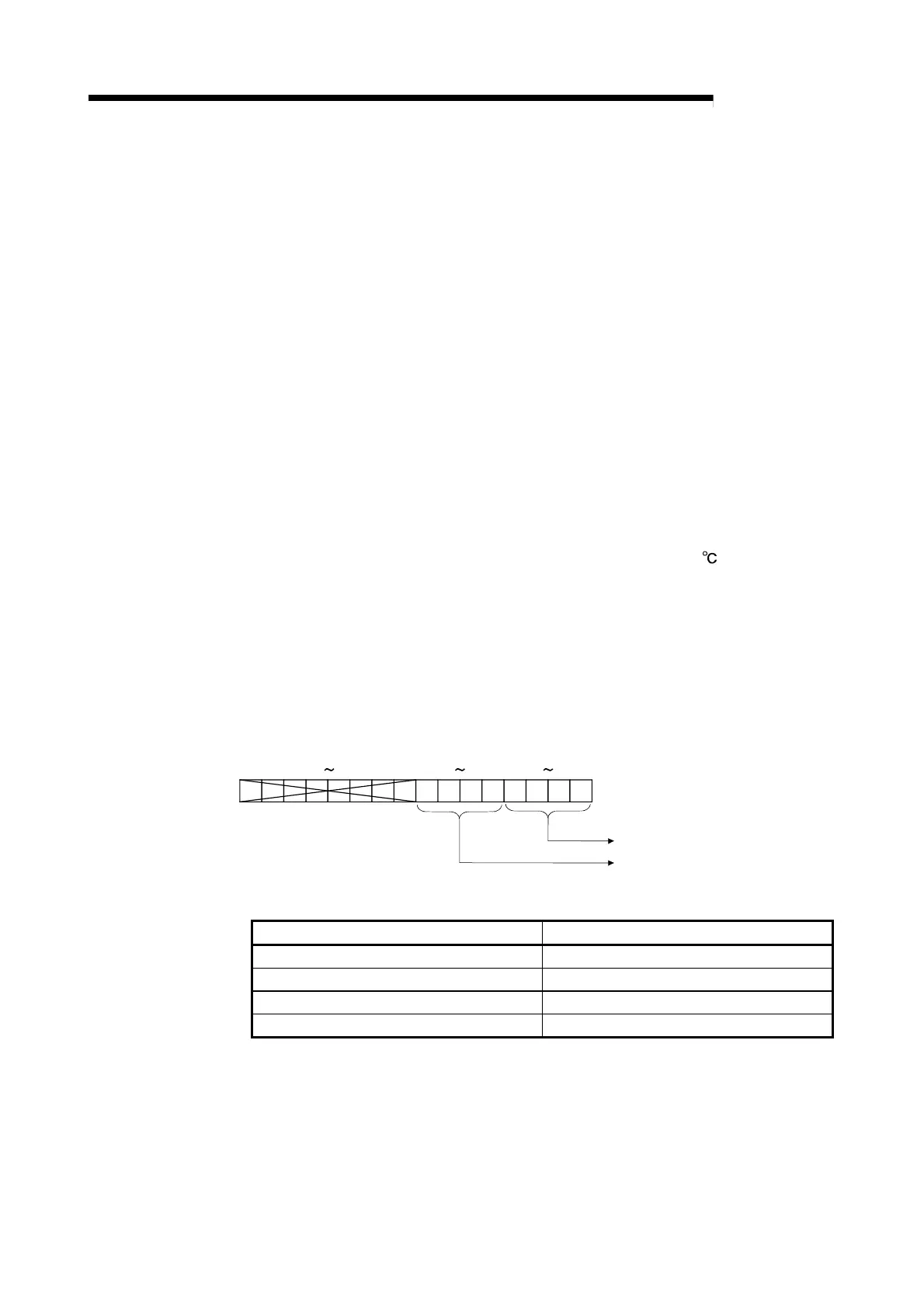

The value is configured with data of each channel 4 bits and stored in the lower

8 bits of buffer memory address 30.

The value of channel 1 is stored in 0 to 3 bits, and the value of channel 2 is

stored in 4 to 7 bits.

b15 b8 b3

CH1 value

CH2 value

b7 b4 b0

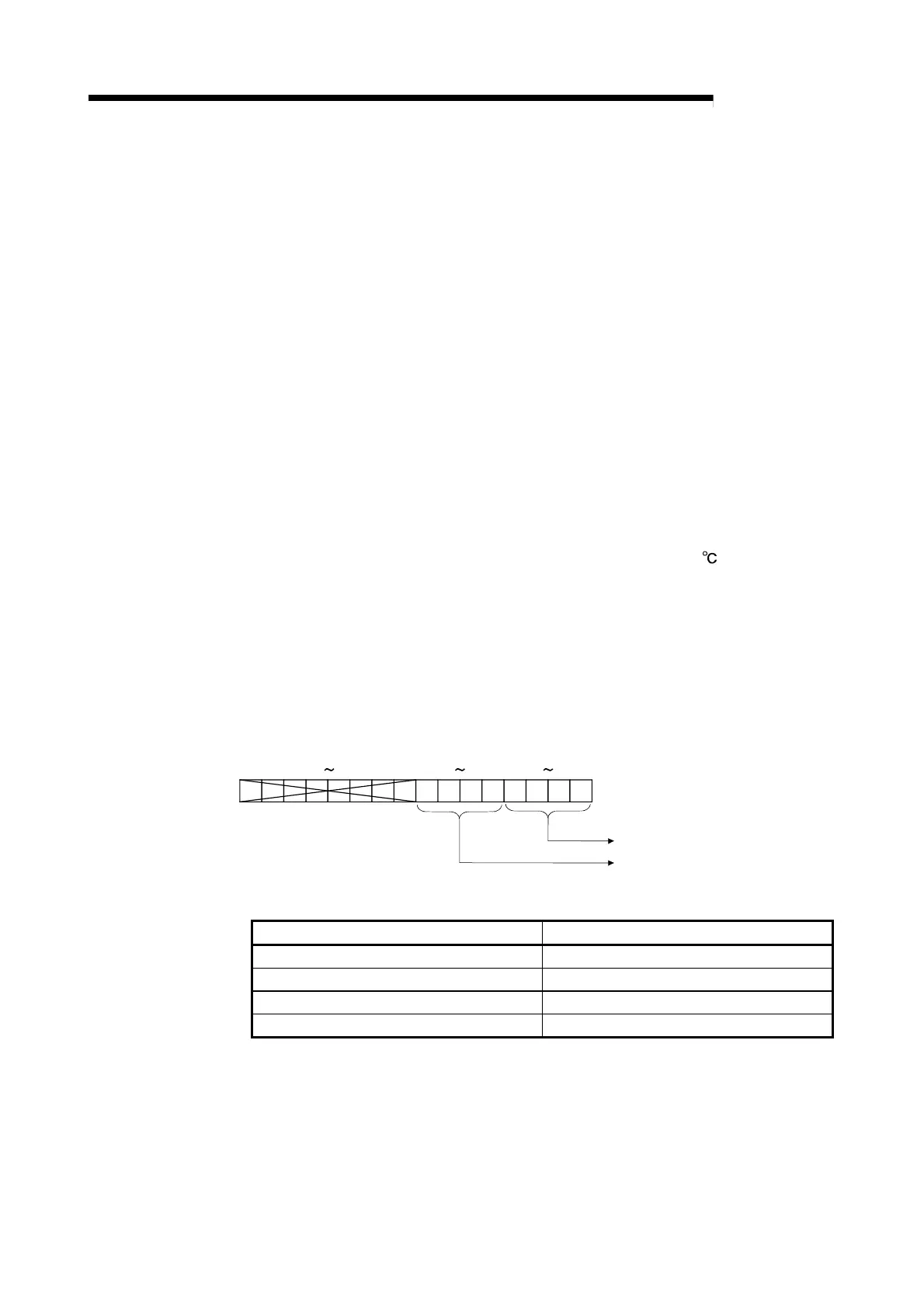

(2) The following describes the values to be stored.

Control mode Stored value

Normal control mode 0

Manual control mode 1

Program control mode 2

Manual control mode 3

(3) Set the manipulated value (MV) in manual control mode 1 and manual control

mode 2 after checking that the stored value is changed to 1 or 3.

Loading...

Loading...