6 - 22 6 - 22

MELSEC-Q

6 PROGRAMMING

*2: Before executing program control, PID constants of zone1 and zone2 need to be set by the

program control auto tuning execution command (X111).

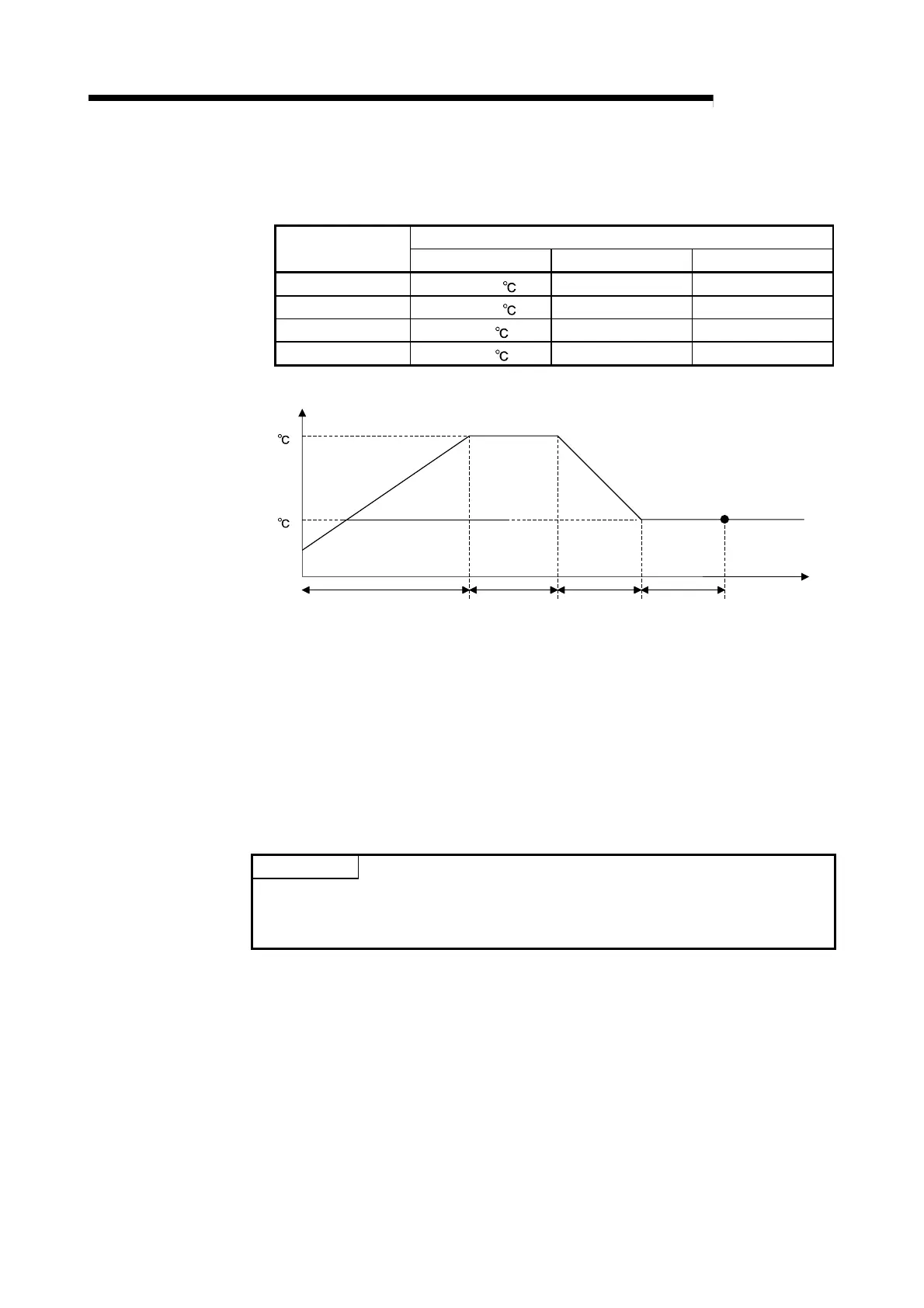

When program control is executed by the set pattern, it operates as follows.

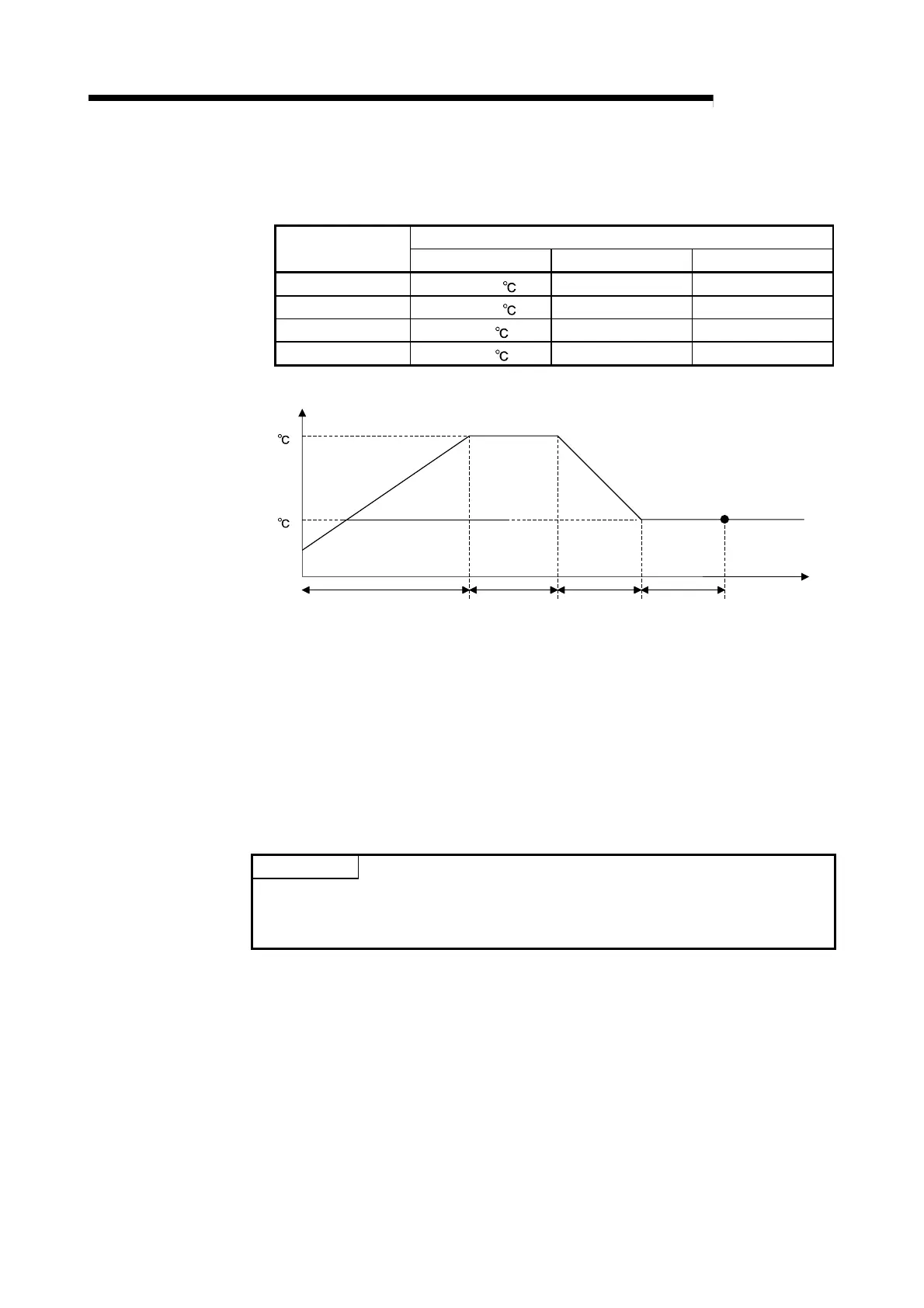

Setting value

Segment number

Set value Executing time Zone PID data No.

Segment 1 1500 (150 ) 200 (200s) 2 (Zone 2)

Segment 2 1500 (150 ) 100 (100s) 2 (Zone 2)

Segment 3 500 (50 ) 100 (100s) 1 (Zone 1)

Segment 4 500 (50 ) 100 (200s) 1 (Zone 1)

Zone PID=2 Zone PID=2 Zone PID=1 Zone PID=1

Segment 1

200s

Segment 2

100s

Segment 3

100s

Segment 4

100s

Process Value (PV)

150

50

time

*3: After setting parameter by the cascade control setting command (X115), execute cascade

control by turning on the cascade control switching command (X108).

In this program example, the parameter setting for cascade control and the other parameter

settings (normal control, program control, and manual control2) cannot be set at the same

time.

After setting the parameter for cascade control, do not use the normal control mode switching

command (X104), program control mode switching command (X105), and manual control

mode 2 switching command (X107).

POINT

For details on the MELSECNET/H remote I/O network, refer to the Q

Corresponding MELSECNET/H Network System Reference Manual (Remote I/O

Network).

Loading...

Loading...