S5 THERMAL MODEL 4. SETPOINT PROGRAMMING

4-28

Û

ÛÛ

Û

ESCAPE

ESCAPEESCAPE

ESCAPE

MESSAGE

MESSAGEMESSAGE

MESSAGE

Ú

ÚÚ

Ú

7,0(#72#75,3#$7

9183[#)/$=#;18#V

B1>75*ð â%ã)))))â)ð CD5@* â!

>?D5*ðDXYcð]UccQWUðSQ^^_dðRUðQ\dUbUTðYVðCdQ^TQbTð3ebfUðCdi\UððYcðcU\USdUT

Û

ÛÛ

Û

ESCAPE

ESCAPEESCAPE

ESCAPE

MESSAGE

MESSAGEMESSAGE

MESSAGE

Ú

ÚÚ

Ú

7,0(#72#75,3#$7

:133[#)/$=#:16#V

B1>75*ð â%ã)))))â)ð CD5@* â!

>?D5*ðDXYcð]UccQWUðSQ^^_dðRUðQ\dUbUTðYVðCdQ^TQbTð3ebfUðCdi\UððYcðcU\USdUT

Û

ÛÛ

Û

ESCAPE

ESCAPEESCAPE

ESCAPE

MESSAGE

MESSAGEMESSAGE

MESSAGE

Ú

ÚÚ

Ú

7,0(#72#75,3#$7

:183[#)/$=#916#V

B1>75*ð â%ã)))))â)ð CD5@* â!

>?D5*ðDXYcð]UccQWUðSQ^^_dðRUðQ\dUbUTðYVðCdQ^TQbTð3ebfUðCdi\UððYcðcU\USdUT

Û

ÛÛ

Û

ESCAPE

ESCAPEESCAPE

ESCAPE

MESSAGE

MESSAGEMESSAGE

MESSAGE

Ú

ÚÚ

Ú

7,0(#72#75,3#$7

;133[#)/$=#819#V

B1>75*ð â%ã)))))â)ð CD5@* â!

>?D5*ðDXYcð]UccQWUðSQ^^_dðRUðQ\dUbUTðYVðCdQ^TQbTð3ebfUðCdi\UððYcðcU\USdUT

Û

ÛÛ

Û

ESCAPE

ESCAPEESCAPE

ESCAPE

MESSAGE

MESSAGEMESSAGE

MESSAGE

Ú

ÚÚ

Ú

7,0(#72#75,3#$7

4313[#)/$=#819#V

B1>75*ð â%ã)))))â)ð CD5@* â!

>?D5*ðDXYcð]UccQWUðSQ^^_dðRUðQ\dUbUTðYVðCdQ^TQbTð3ebfUðCdi\UððYcðcU\USdUT

Û

ÛÛ

Û

ESCAPE

ESCAPEESCAPE

ESCAPE

MESSAGE

MESSAGEMESSAGE

MESSAGE

Ú

ÚÚ

Ú

7,0(#72#75,3#$7

4813[#)/$=#819#V

B1>75*ð â%ã)))))â)ð CD5@* â!

>?D5*ðDXYcð]UccQWUðSQ^^_dðRUðQ\dUbUTðYVðCdQ^TQbTð3ebfUðCdi\UððYcðcU\USdUT

Û

ÛÛ

Û

ESCAPE

ESCAPEESCAPE

ESCAPE

MESSAGE

MESSAGEMESSAGE

MESSAGE

Ú

ÚÚ

Ú

7,0(#72#75,3#$7

5313[#)/$=#819#V

B1>75*ð â%ã)))))â)ð CD5@* â!

>?D5*ðDXYcð]UccQWUðSQ^^_dðRUðQ\dUbUTðYVðCdQ^TQbTð3ebfUðCdi\UððYcðcU\USdUT

Û

ÛÛ

Û

ESCAPE

ESCAPEESCAPE

ESCAPE

MESSAGE

MESSAGEMESSAGE

MESSAGE

Ú

ÚÚ

Ú

0,1,080#$//2:$%/(

/,1(#92/7$*(=;3(

B1>75*ð' ã)%ð CD5@*!

>?D5*ðDXYcð]UccQWUðcUU^ð_^\iðYVðF_\dQWUð4U`U^TU^dð3ebfUðCdi\UðYcðcU\USdUT

Û

ÛÛ

Û

ESCAPE

ESCAPEESCAPE

ESCAPE

MESSAGE

MESSAGEMESSAGE

MESSAGE

Ú

ÚÚ

Ú

67$//#&855(17###0,1

9OLQH=#71;3#[#)/$

B1>75*ð"â ã!%â ð CD5@* â !

>?D5*ðDXYcð]UccQWUðcUU^ð_^\iðYVðF_\dQWUð4U`U^TU^dð3ebfUðCdi\UðYcðcU\USdUT

Û

ÛÛ

Û

ESCAPE

ESCAPEESCAPE

ESCAPE

MESSAGE

MESSAGEMESSAGE

MESSAGE

Ú

ÚÚ

Ú

6$)(#67$//#7,0(##

0,1#9OLQH=#5313#V

B1>75*ð â%ã)))â)ð CD5@* â!

>?D5*ðDXYcð]UccQWUðcUU^ð_^\iðYVðF_\dQWUð4U`U^TU^dð3ebfUðCdi\UðYcðcU\USdUT

Û

ÛÛ

Û

ESCAPE

ESCAPEESCAPE

ESCAPE

MESSAGE

MESSAGEMESSAGE

MESSAGE

Ú

ÚÚ

Ú

$&&(/1#,17(56(&7##

0,1#9OLQH=#61;3[)/$

B1>75*ð"â ã9cdQ\\ð0ð]Y^ðF\Y^U CD5@* â !

>?D5*ðDXYcð]UccQWUðcUU^ð_^\iðYVðF_\dQWUð4U`U^TU^dð3ebfUðCdi\UðYcðcU\USdUT

Û

ÛÛ

Û

ESCAPE

ESCAPEESCAPE

ESCAPE

MESSAGE

MESSAGEMESSAGE

MESSAGE

Ú

ÚÚ

Ú

67$//#&855(17###433(

9OLQH=#9133#[#)/$

B1>75*ð"â ã!%â ð CD5@* â !

>?D5*ðDXYcð]UccQWUðcUU^ð_^\iðYVðF_\dQWUð4U`U^TU^dð3ebfUðCdi\UðYcðcU\USdUT

Û

ÛÛ

Û

ESCAPE

ESCAPEESCAPE

ESCAPE

MESSAGE

MESSAGEMESSAGE

MESSAGE

Ú

ÚÚ

Ú

6$)(#67$//#7,0(##

433(#9OLQH=#4313#V

B1>75*ð â%ã)))â)ð CD5@* â!

>?D5*ðDXYcð]UccQWUðcUU^ð_^\iðYVðF_\dQWUð4U`U^TU^dð3ebfUðCdi\UðYcðcU\USdUT

Û

ÛÛ

Û

ESCAPE

ESCAPEESCAPE

ESCAPE

MESSAGE

MESSAGEMESSAGE

MESSAGE

×

××

×

$&&(/1#,17(56(&7##

433(#9OLQH=#8133[)/$

B1>75*ð"â ã9cdQ\\ð0ð! ëF\Y^U CD5@* â !

>?D5*ðDXYcð]UccQWUðcUU^ð_^\iðYVðF_\dQWUð4U`U^TU^dð3ebfUðCdi\UðYcðcU\USdUT

The overload curve accounts for motor heating during stall, acceleration, and running in both the stator and the rotor. The

Overload Pickup setpoint dictates where the running overload curve begins as the motor enters an overload condition. This is

useful for service factor motors as it allows the pickup level to be defined. The curve is effectively cut off at current values

below this pickup.

Motor thermal limits consist of three distinct parts based on the three conditions of operation, locked rotor or stall, acceleration, and run-

ning overload. Each of these curves may be provided for both a hot motor and a cold motor. A hot motor is defined as one that has been

running for a period of time at full load such that the stator and rotor temperatures have settled at their rated temperature. A cold motor

is defined as a motor that has been stopped for a period of time such that the stator and rotor temperatures have settled at ambient

temperature. For most motors, the distinct characteristics of the motor thermal limits are formed into one smooth homogeneous curve.

Sometimes only a safe stall time is provided. This is acceptable if the motor has been designed conservatively and can easily perform

its required duty without infringing on the thermal limit. In this case, the protection can be conservative and process integrity is not com-

promised. If a motor has been designed very close to its thermal limits when operated as required, then the distinct characteristics of the

thermal limits become important.

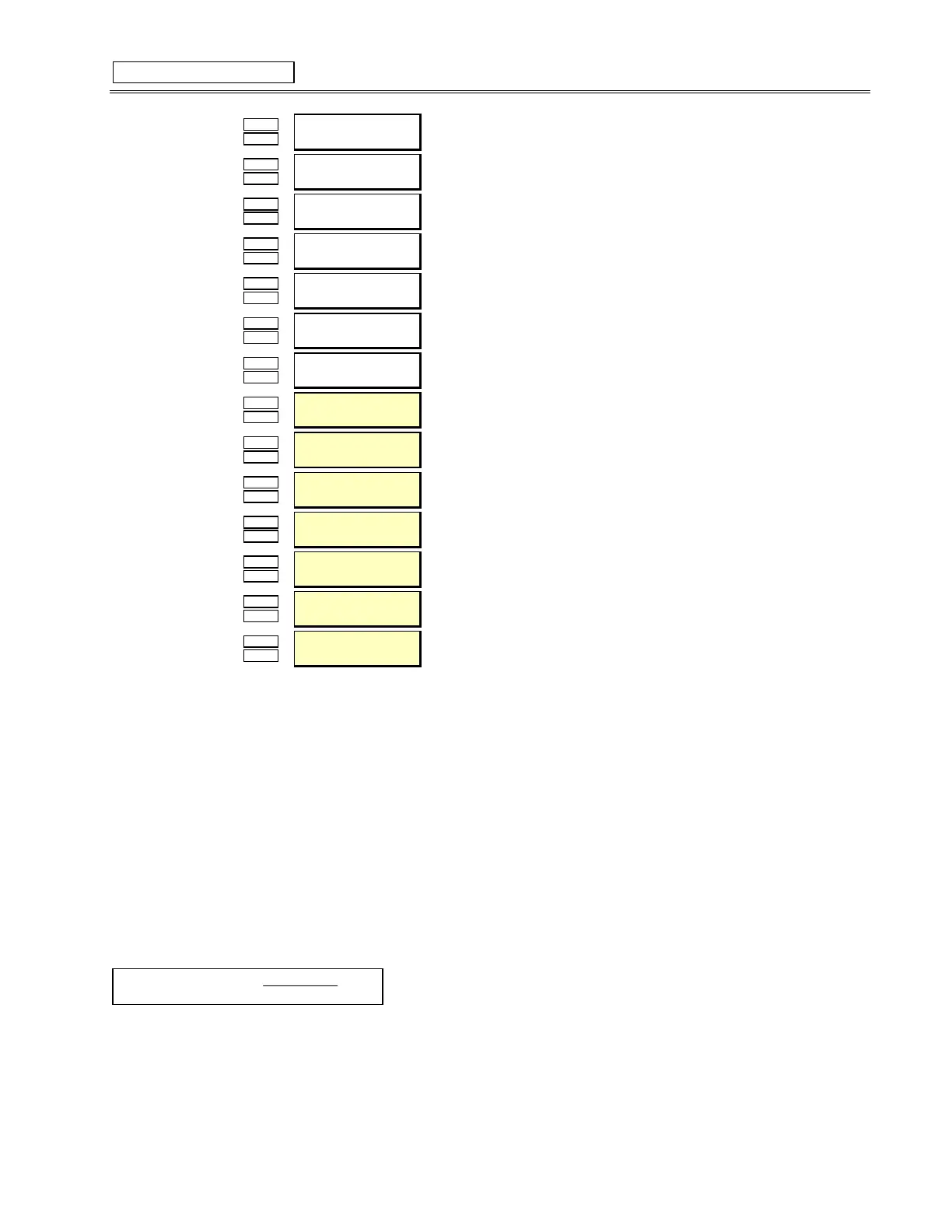

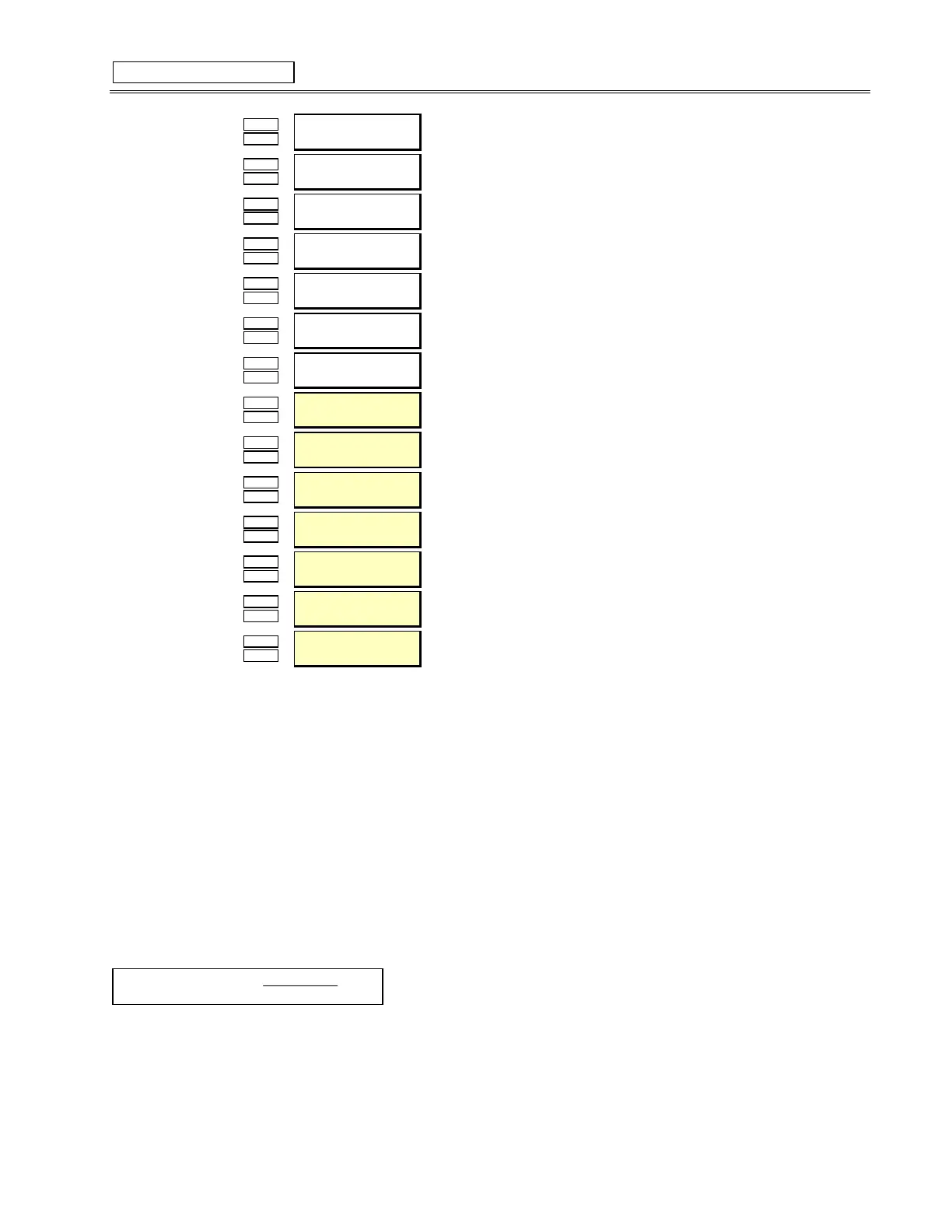

The SR469 overload curve can take one of three formats, Standard, Custom Curve, or Voltage Dependent. Regardless of which curve

style is selected, the SR469 will retain thermal memory in the form of a register called Thermal Capacity Used. This register is updated

every 100ms using the following equation:

TC TC

ms

time to trip

used

t

used

tms

=+

−

100

100

100%

__

*

where: time_to_trip = time taken from the overload curve @ Ieq as a function of FLA

The overload protection curve should always be set slightly lower than the thermal limits provided by the manufacturer. this will ensure

that the motor is tripped before the thermal limit is reached.

If the motor starting times are well within the safe stall times, it is recommended that the SR469 Standard Overload Curve be used. The

standard overload curves are a series of 15 curves with a common curve shape based on typical motor thermal limit curves (see Figure

4-8 and Table 4-2).

Loading...

Loading...