NewSonic SonoDur2 Issue 04 09/2016 Page 10

Besides surface roughness, material properties such as texture, mechanical tensions, layer structures

and underground also play a role for measurement value variations and deviations from nominal

values.

The above information is based on experience where the real practical situation has to be tested on

the material and part in question.

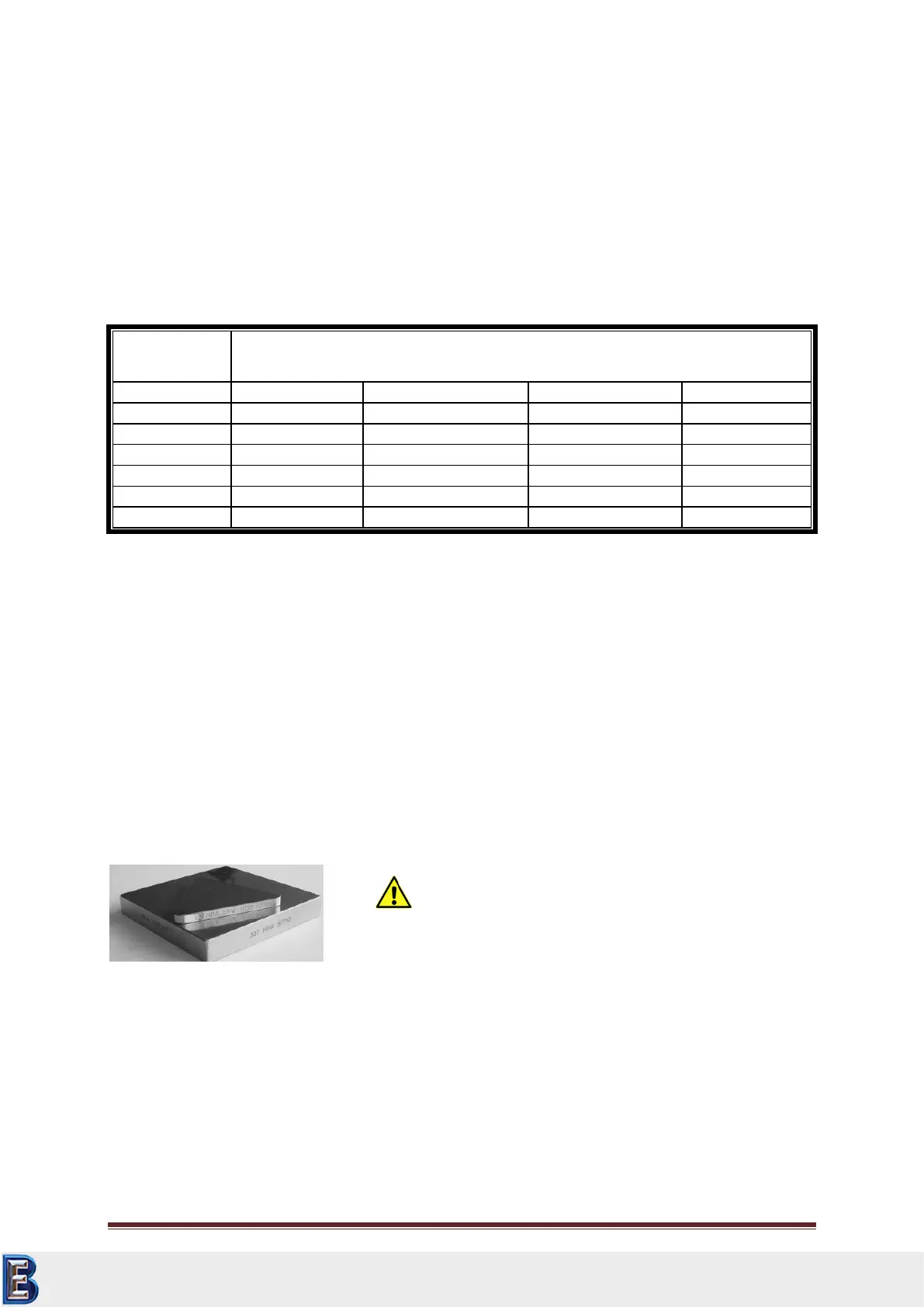

The permissible limiting deviations for average values on hardness reference blocks apply in the

assessment of measurement accuracy of UCI devices - refer to table below (from DIN 50159-1/2):

Table 2-4

All SonoDur2 probes must meet internal standards with max. ± 3% from 3 -5 measurements on

hardness reference blocks (see Technical Data – SonoDur2, Page 65).

In accordance with the UCI standard DIN 50159-1/2, hardness reference blocks with specific

dimensions are mandatory for the testing, namely a minimum thickness of 15mm and a diameter of

80mm. These blocks are often hardly obtainable. However, docking the hardness reference block to a

flat hard surface, most preferably made of steel, has much higher significance than the "correct"

dimension. Depending on the support material (wood, cloth, etc.), test force and test position, test

reference blocks can develop macroscopically very complex panel vibrations that can complicate the

performance of an UCI measurement or make it even impossible. Triangular Vickers hardness

reference blocks with a thickness of 6 mm (see image below) are very much prone to panel vibrations

and therefore it must definitely be ensured that these are always well coupled!

Figure 2.1

The best way to derive this type of influence is to observe the ranges of a measurement series.

Depending on the probe and hardness, mean values are furthermore generally more or less

significantly lower or higher than the indications provided on the reference block itself.

Caution is also needed on some Rockwell reference blocks (HRC), if they are only roughly grounded

and therefore depending on the test force, may tend to indicate too low UCI hardness values.

Attention

These triangle reference blocks need well coupling!

Your Complete Source for

Testing Equipment. Since 1969!

www.BergEng.com

Berg Engineering & Sales Company, Inc.

Tel 847-577-3980

info@bergeng.com

Loading...

Loading...