NewSonic SonoDur2 Issue 04 09/2016 Page 9

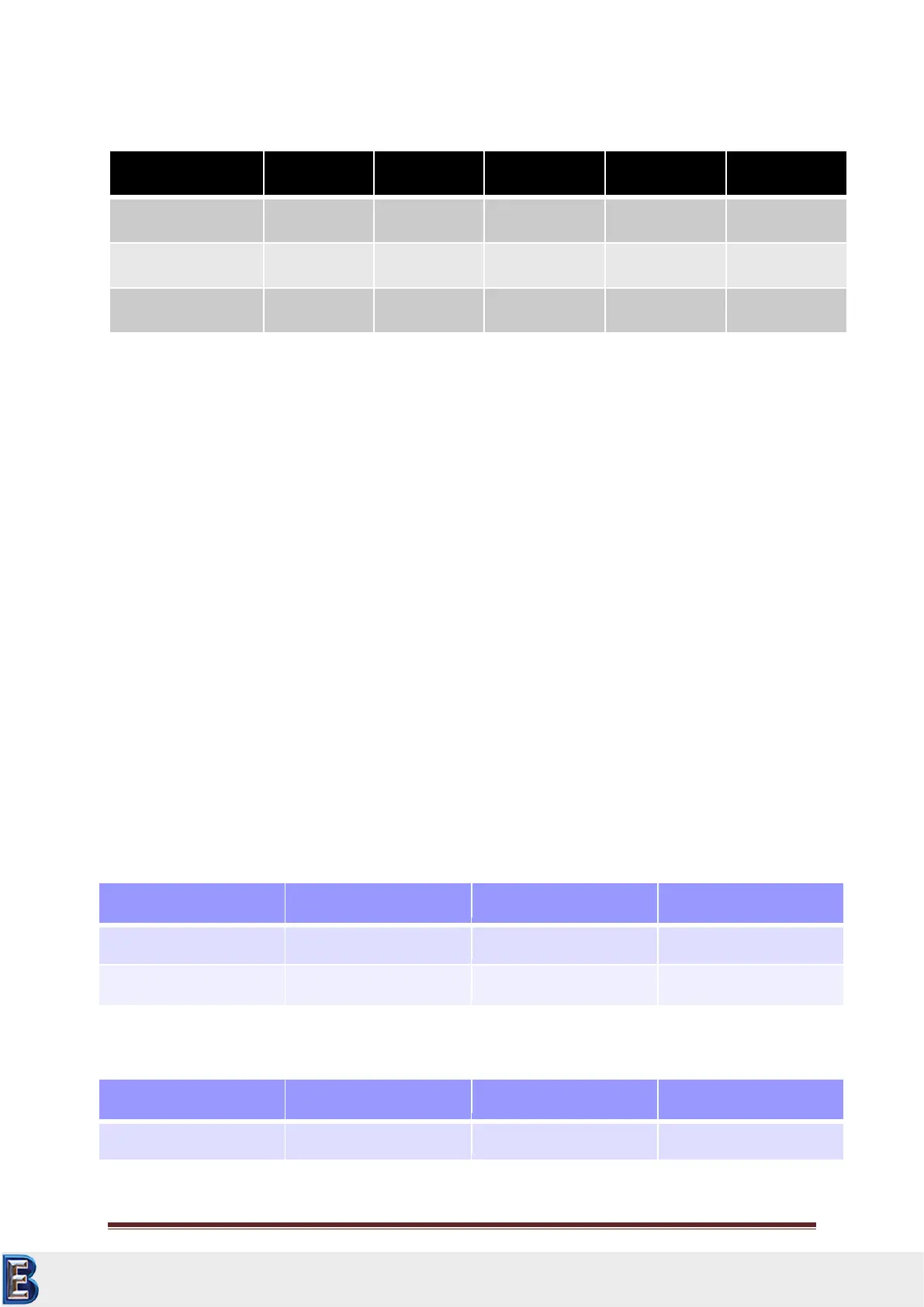

The table below shows a few examples of the more significant penetration depth (in “µm”):

Table 2-1

In general, the nature of the component surface in the range of low-load hardness testing, are of

particular importance. High dispersion of measured values can be an indication of excessive surface

roughness. In this case, reworking of the surface with suitable abrasives as well as a re-measurement

may be recommended.

Some other influencing factors are summarized in the following:

Minimum layer thickness: 10 x d (no noticeable influence by the base material after

adjustment)

Minimum material thickness without coupling: > 3 mm (component resonances can falsify

measurement values)

Minimum mass without coupling: > 0.3 kg (component resonances can falsify measurement

values or may make it impossible to perform a measurement)

Minimum distance from the component edge of the element = 3 x Ld, between the

indentations = 6 x Ld

The surface roughness should be much less as the penetration depth (< 1/5 x d)

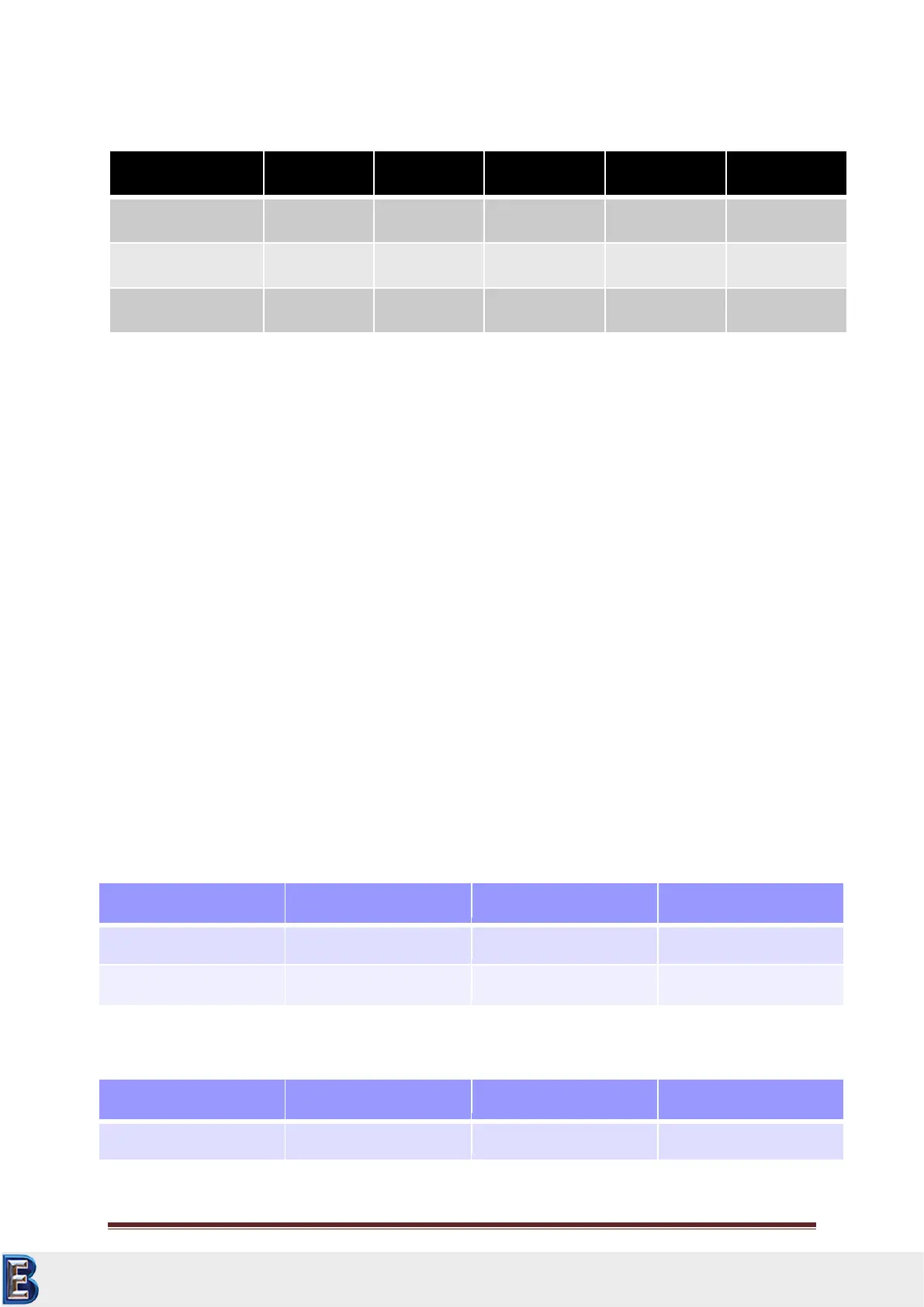

In the latest issue of the German standard DIN 50159-1,2-2015 examples for the required surface

roughness Ra for different test loads and as well for the grit size for the manual grinding work are

given, see tables below:

Tabelle 2-2: Guidelines for the maximum surface roughness according to EN ISO 6507 (Vickers) and

information given in the standard ASTM A 1038

Tabelle 2-3: Surface roughness after manual grinding using sand paper with various grit size (FEPA-

Standard, „Federation of the European Producers of Abrasives“).

Your Complete Source for

Testing Equipment. Since 1969!

www.BergEng.com

Berg Engineering & Sales Company, Inc.

Tel 847-577-3980

info@bergeng.com

Loading...

Loading...