NMC-WOLLARD 2021Truax Blvd., Eau Claire, WI 54703, Phone (715) 835-3151, Fax (715) 835-6625

M140 Tow Tractor Manual No. 46054

PAGE 1-42

CHAPTER 2 MAINTENANCE

AUGUST 31, 2008

1 SERVICING

5. Rotate wheel end until plug hole is at its lowest position.

6. Remove drain plugs. Inspect and remove metal particles from plugs. Normally,

there may be damage inside the axle. Notify your supervisor of this condition.

7. When oil has drained, apply a non-hardening sealing compound (like #51 or

8. Turn wheel ends so plug holes are above level of the axle shaft. If necessary,

install plugs temporarily to prevent new oil from leaking out.

85W-140) to level of plug hole.

axle shaft. Fill wheel ends with oil (80W-90 or 85W-140) to level of plug hole.

11. Apply a non-hardening sealing compound (like #51 or equivalent) to plugs and

install and tighten plugs.

12. Install wheels according to 2-4 - 4.2.

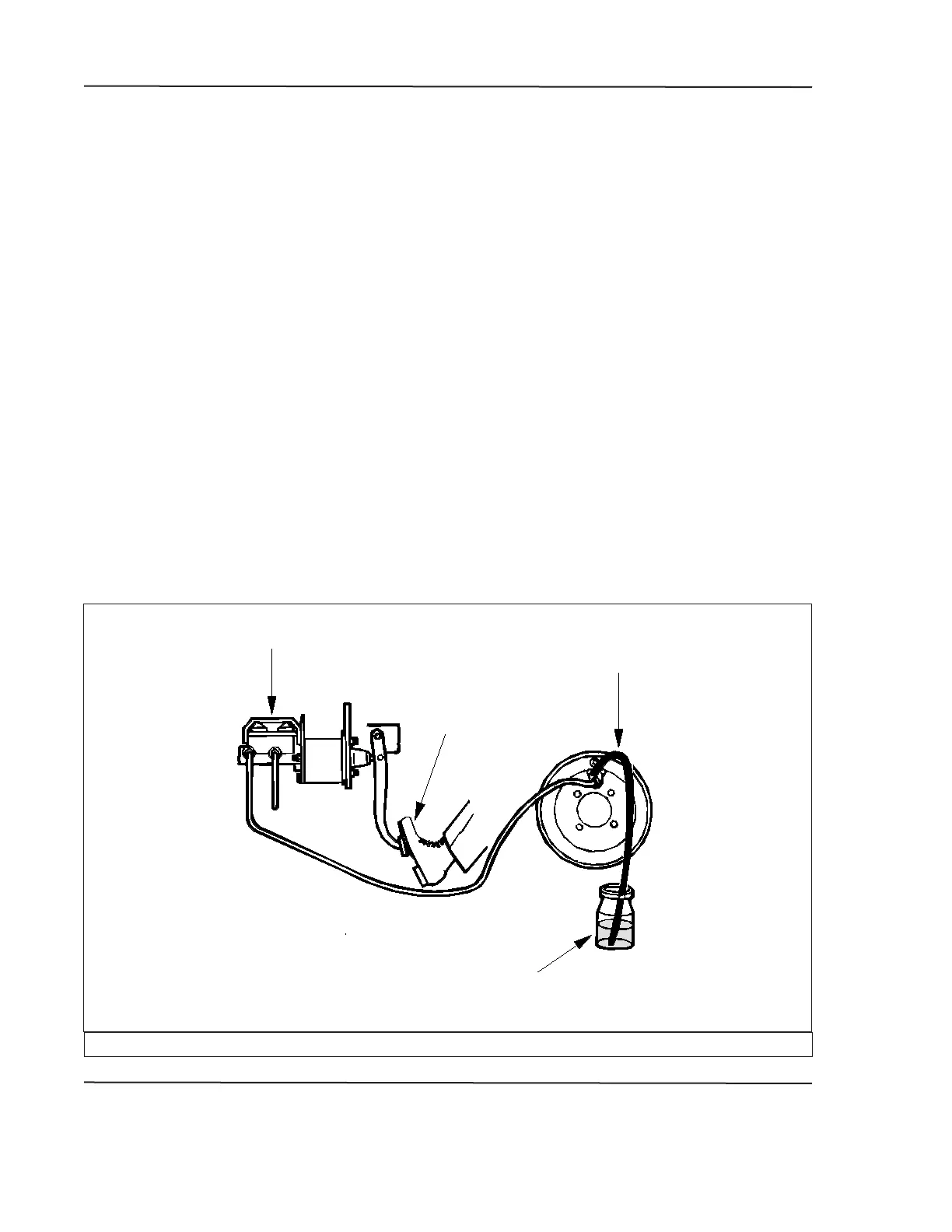

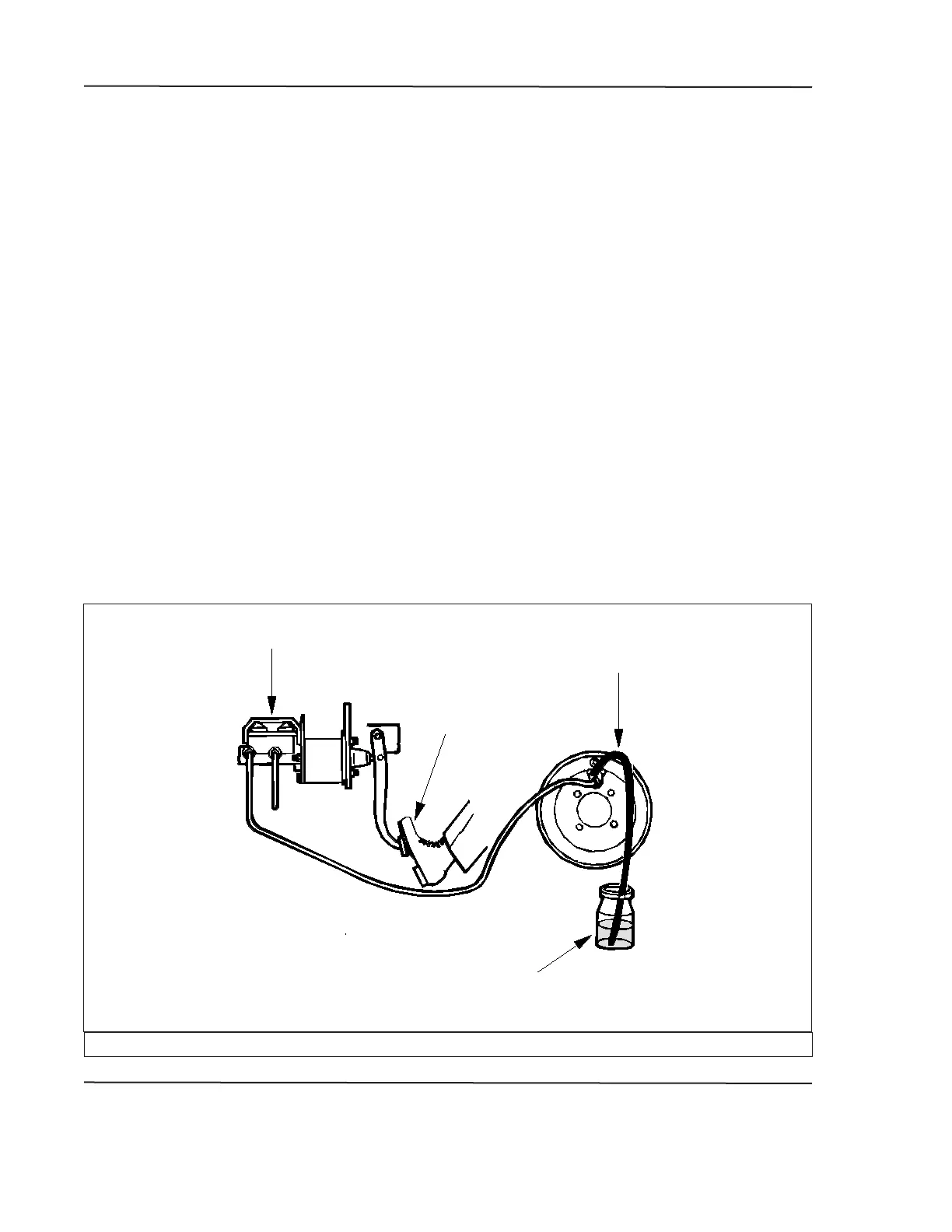

1.10 BLEEDING THE BRAKES

Figure 14

Bleeding the brakes means removing air from the brake system. Air in the system

causes a springy or spongy feel when braking. Bleeding consists of pumping fresh

caliper bleeder valves.

Jar with

brake fluid

Hose

Press slowly on

brake pedal

FIGURE 14. TYPICAL SETUP FOR BLEEDING AIR FROM THE BRAKE SYSTEM

Loading...

Loading...