NMC-WOLLARD 2021Truax Blvd., Eau Claire, WI 54703, Phone (715) 835-3151, Fax (715) 835-6625

M140 Tow Tractor Manual No. 46054

PAGE 1-37

CHAPTER 2 MAINTENANCE

AUGUST 31, 2008

1 SERVICING

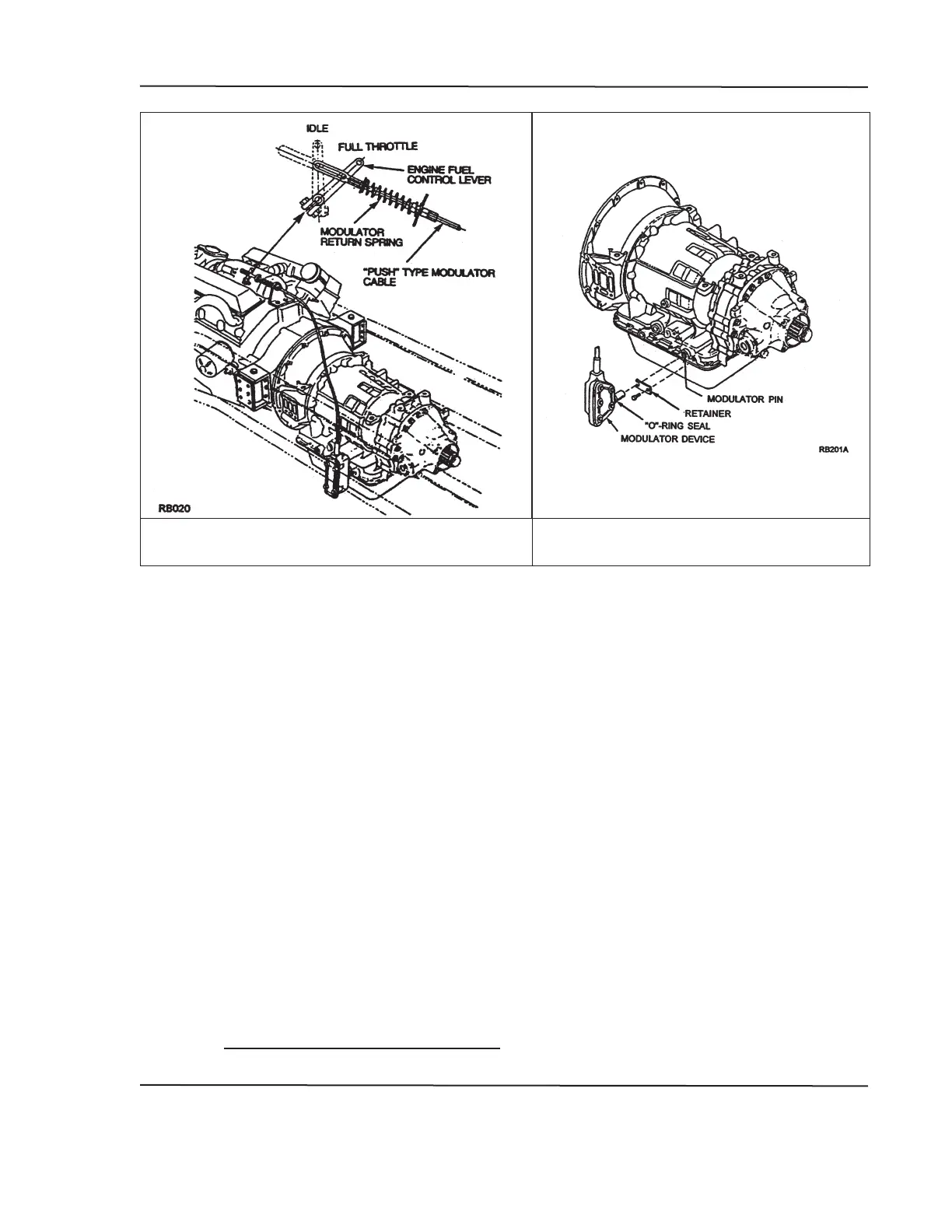

FIGURE 12. MECHANICAL MODULATOR

INSTALLATION

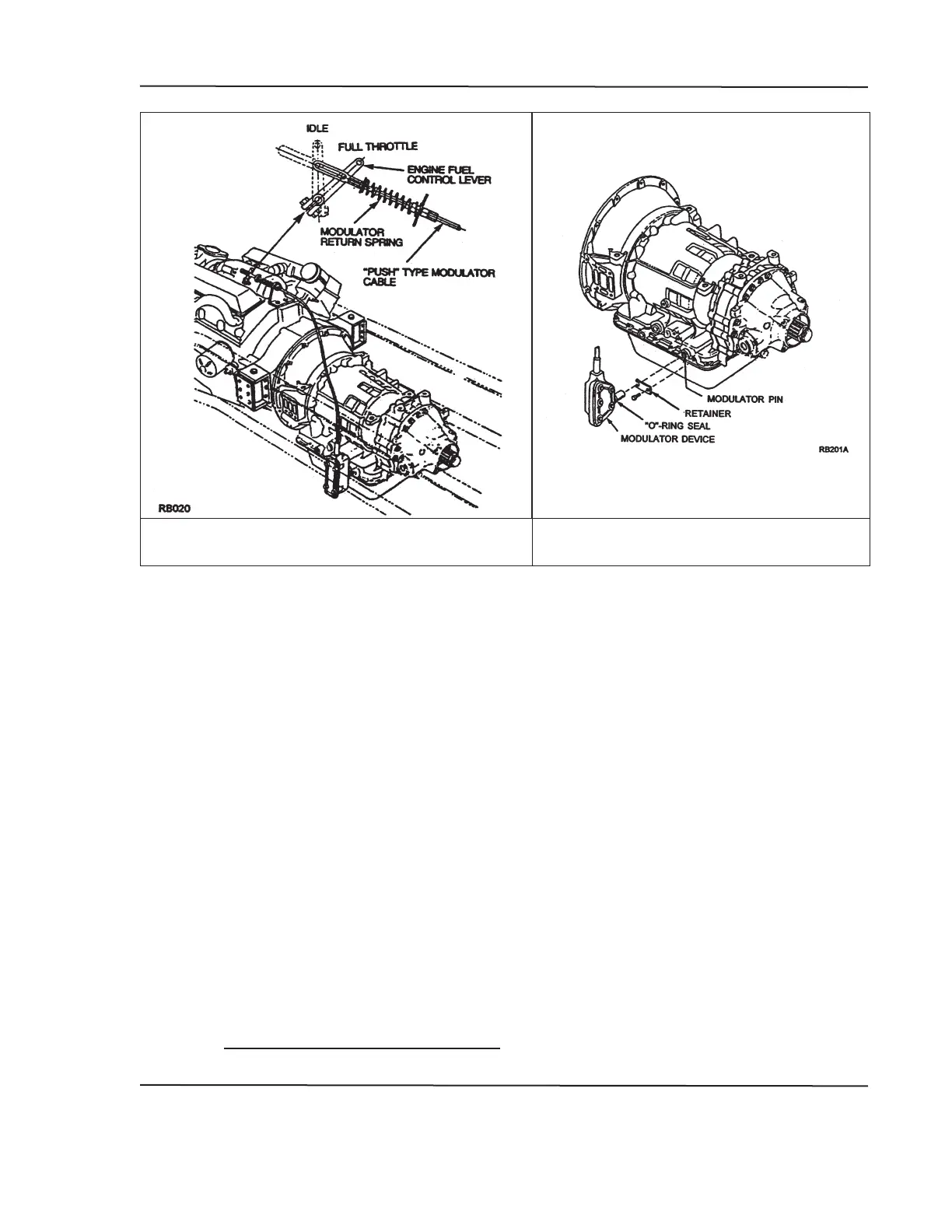

FIGURE 13. MECHANICAL

MODULATOR COMPONENTS

Design requirements for a mechanical modulator are shown on separate Shift

Modulator Installation Drawings for each transmission series. The mounting

location of the modulator is shown on both the Shift Modulator and Basic

Installation Drawing for each transmission.

The system design should provide for ease of installation and adjustment.

Adjust at full throttle position to insure maximum speed upshifts at full throttle.

The modulator must provide a force against the transmission modulator pin,

in proportion to cable travel, as described on the appropriate Shift Modulator

“push” or “pull” cable motion when the fuel lever moves from closed to full

throttle position.

Figure 12 illustrates a recommended type of connection of the end of a “push

type” modulator cable to the engine fuel lever. This type of arrangement will

allow the fuel lever to return to idle even if the actuator binds somewhere in

its travel between idle and full throttle positions. With this system, a return

spring is required on the actuator linkage to insure that the actuator follows

the movement of the fuel lever (throttle). The spring should be designed for

the particular installation and have a low spring rate to keep the additional

accelerator pedal force as low as possible. For suppliers of the mechanical

modulator, refer to the Support Equipment section of the appropriate

Transmission Installation Manual.

Loading...

Loading...