⚫

Measures against radio noise

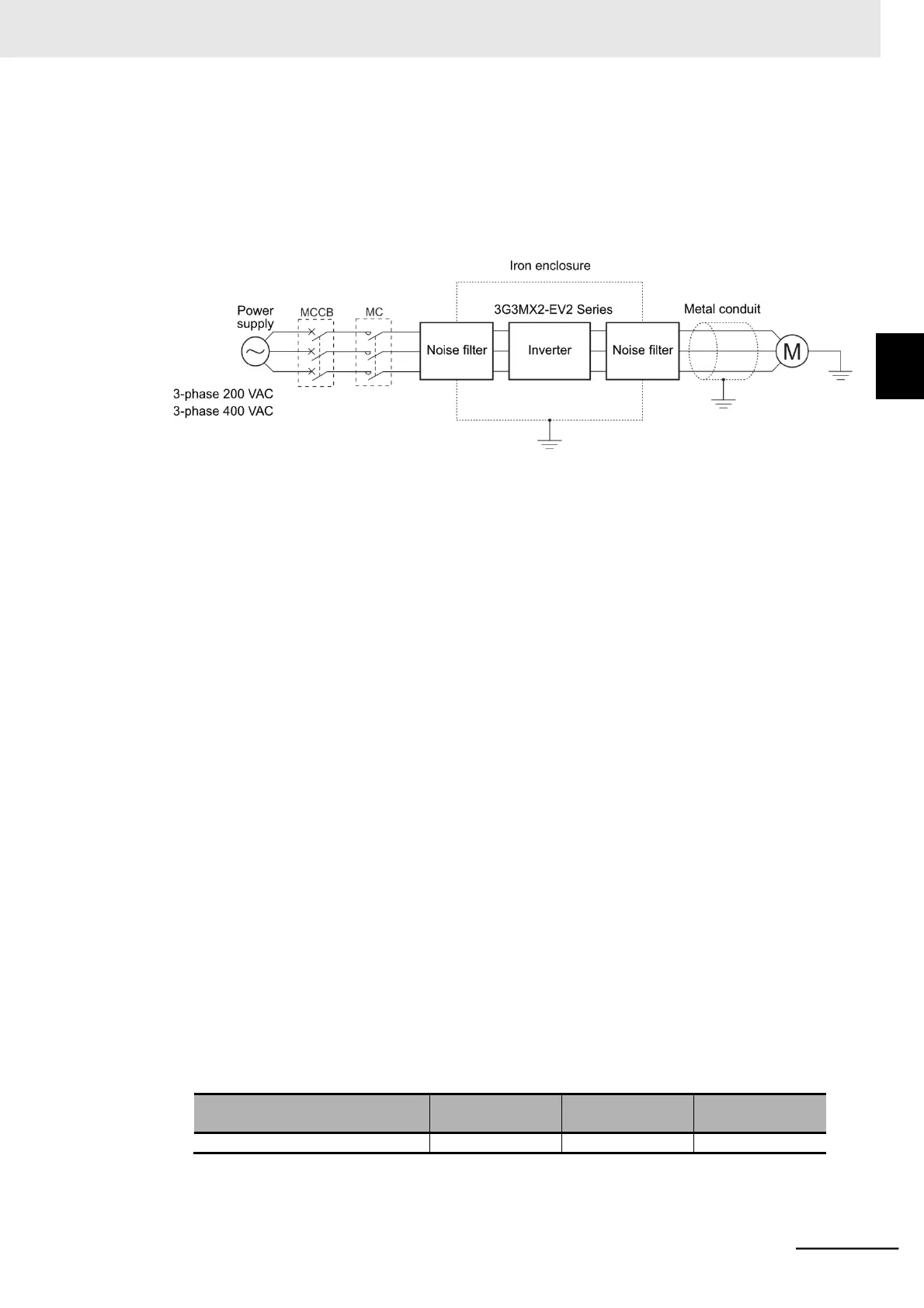

Besides the I/O wires, radio noise is radiated from the inverter itself.

This radio noise can be reduced by installing noise filters on both the input and output sides of the

inverter and by installing and shielding the inverter body in a grounded iron enclosure etc.

Keep the cables between the inverter and the motor as short as possible.

⚫

Cable length between inverter and motor

If the length of the cables between the inverter and the motor is long, consider how to address the

following problems.

•

Voltage drop in output cables

As the cable length between the inverter and the motor increases, the resistance in the cables

becomes higher and accordingly the amount of voltage drop in the inverter output voltage

becomes larger. This causes a decrease in the voltage that is applied to the motor, which results

in a low output torque.

If the cables are long, take measures to reduce the resistance, for example, by selecting cables

whose wire diameter is larger than specified.

•

Surge in long cables

If the cable length exceeds 20 m, a surge voltage (approximately 1200 V max. for 400-V class)

may be generated at the motor terminal depending on the stray capacitance or inductance of the

cable, which may result in motor burnout. dV/dt output filter is required in that case.

In particular, when using a 400-V class inverter with a cable length of over 20 m, it is recom-

mended to use a dedicated inverter motor. Dedicated inverter motors are designed to support the

above surge voltage level.

•

Leakage current from output cables

As the cable length between the inverter and the motor increases, stray capacitance increases

between the inverter output and the ground. The increase in the stray capacitance on the output

side of the inverter causes an increase of the high-frequency leakage current.

This high-frequency leakage current may negatively affect on the current detector in the inverter

output section or peripheral equipment.

It is recommended to keep the wiring distance between the inverter and the motor at 100 m or

shorter. If your system configuration requires the wiring distance of over 100 m, take measures to

decrease the stray capacitance. The applicable measures are such as not wiring in a metal duct

and using a separate cable for each phase.

In addition, set a carrier frequency appropriate for the wiring distance between the inverter and

the motor according to the table below.

Loading...

Loading...