Multi-function Compact Inverter 3G3MX2-EV2 User’s Manual (I666-E1)

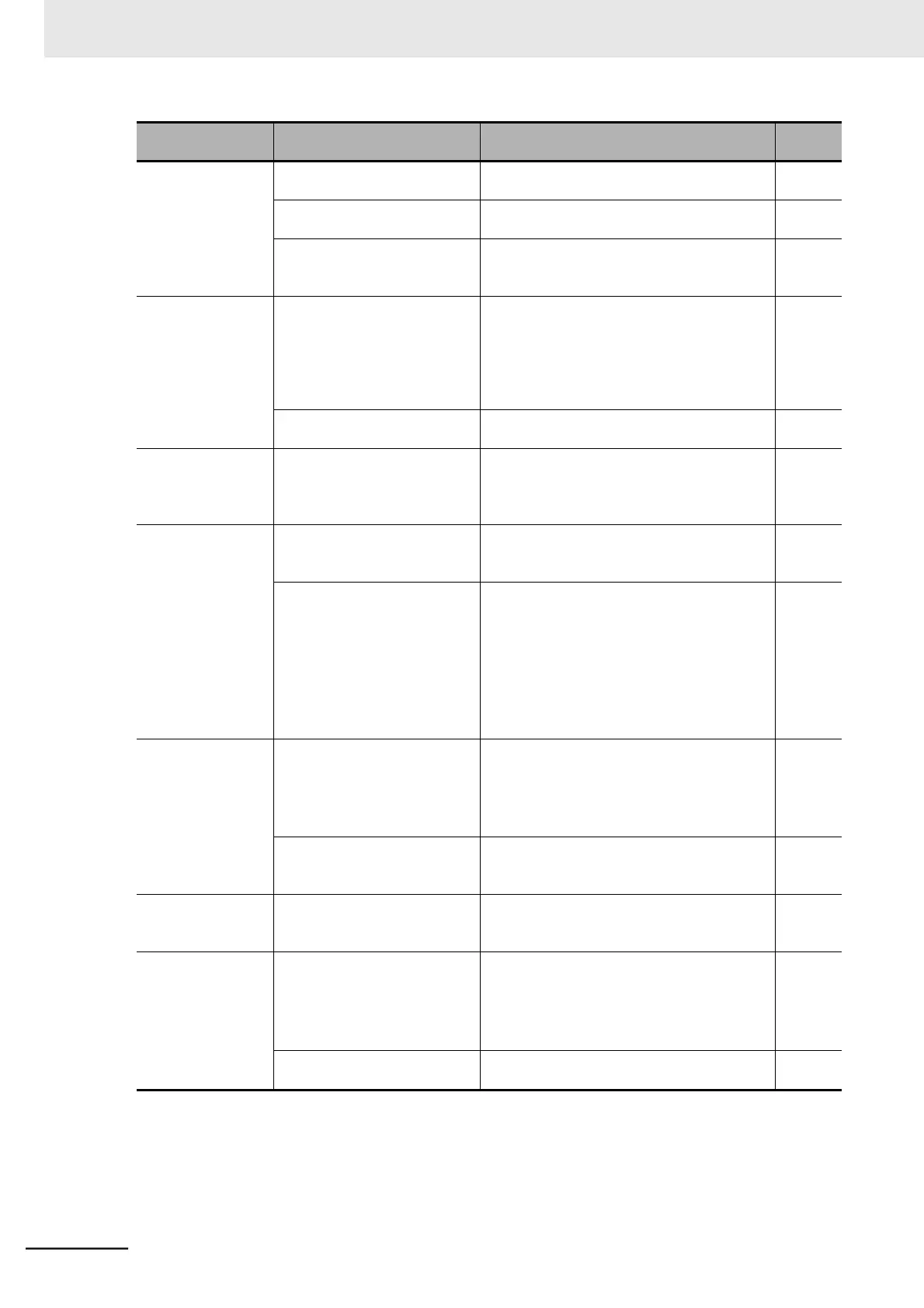

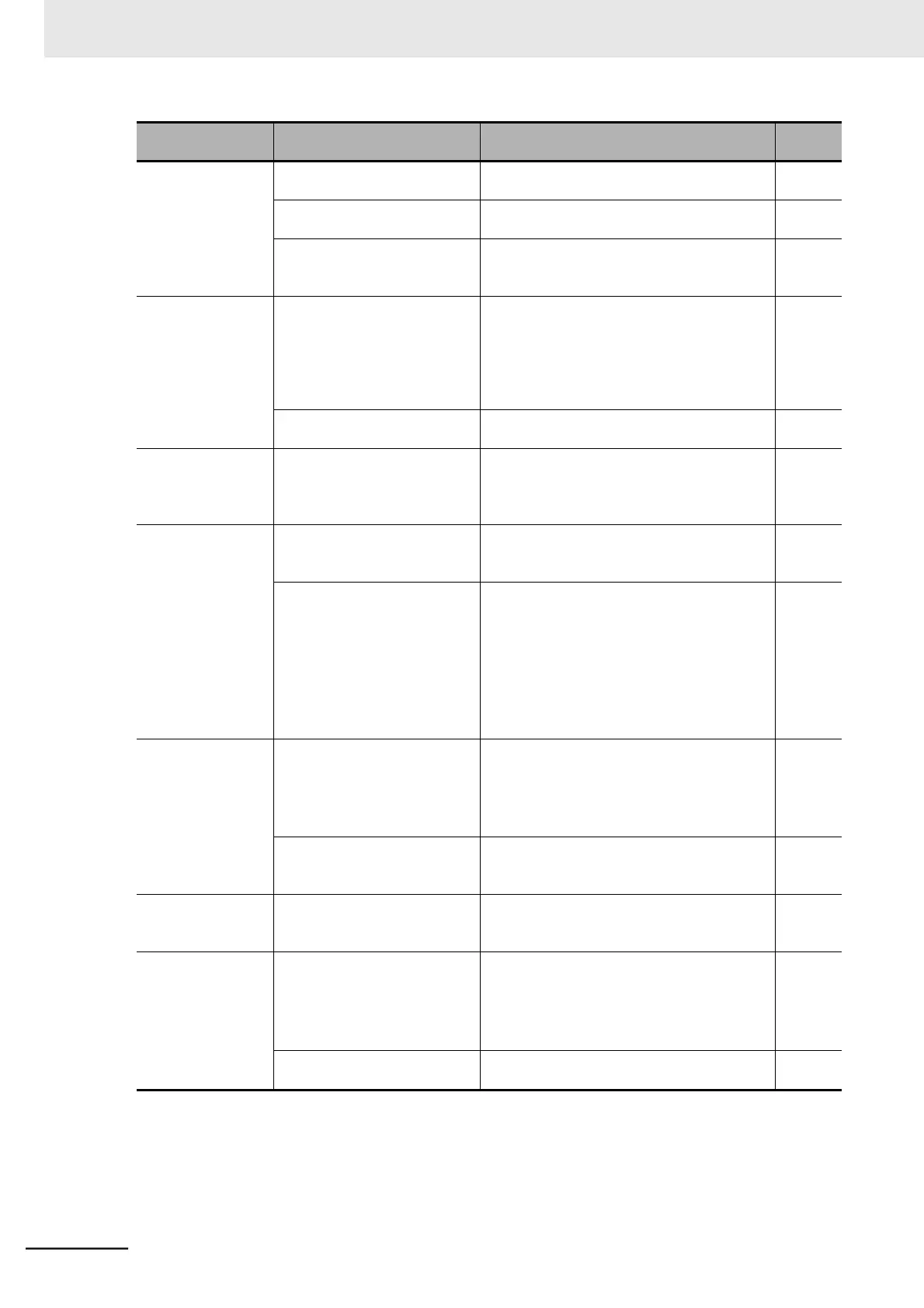

The CX-Drive can-

not be connected

with the inverter.

The CX-Drive version is not

supported.

To connect the CX-Drive to the 3G3MX2-EV2

Series, use Ver. 2.8 or higher.

The inverter software number

does not match.

Set the software number of the connected

inverter in the CX-Drive.

The Modbus mapping endian

function setting is inappropri-

ate.

Set the Modbus Mapping Endian Selection

(P400) to 00 (Big endian).

The inverter does

not accept parame-

ter settings from the

CX-Drive.

The inverter is in operation.

Stop the inverter and, after the motor falls in a

deceleration-stop state, set the parameters

again. Setting b031 to 10 (Data can be

changed during RUN) enables parameter

settings to be changed even when the

inverter is in operation.

The Modbus mapping function

is enabled.

Set the Modbus Mapping Function Selection

(P200) to 00 (Standard Modbus address).

The brake control

function causes an

Overload protec-

tion alarm (E05).

The inverter is in operation with

the brake force.

Turn OFF the RUN command to the inverter

when the brake is applied. Even under DC

injection braking, an Overload protection

alarm may occur.

The brake control

function causes a

Brake error (E36).

The output current does not

reach the set brake release

current value.

Increase the Brake Release Wait Time (b121)

value or decrease the Brake Release Current

(b126).

The brake confirmation signal

is not input.

• Correct the wiring for the brake confirmation

signal (44: BOK). Deallocate the brake con-

firmation function from the multi-function

input setting.

• Review the operation sequence so that the

brake confirmation signal (44: BOK) is input

after the brake is released.

• Replace the brake if it is faulty.

The brake control

function causes the

load to fall.

The set brake release current is

insufficient.

• Increase the Brake Release Current (b126)

value.

• Set the 1st/2nd Control Method

(A044/A244) to 03 (Sensorless vector con-

trol).

The frequency setting for

releasing/forcing the brake is

too low.

Increase the Brake Release Frequency

(b125), Brake Force Frequency (b127), or

Creep Speed Setting (P015) value.

The PM motor

rotates during

startup.

The magnetic pole position of

the motor during startup is

incorrect.

Set the PM Motor Starting Method Selection

(H123) to 01 (Initial pole position estimation

enabled).

The PM motor

causes an Overcur-

rent protection

alarm (E03) during

startup.

Increase the PM Motor Starting Current

(H117) value.

Or perform adjustments according to 6-8-6

Adjustment of PM Motor Mode Settings on

page 6-64.

Reduce the load. Or increase the accelera-

tion/deceleration time.

Loading...

Loading...