Frequency and Maximum Frequency of Motor on page 5-19 and 6-1-2

Basic Motor Parameter Set-

tings on page 6-4.

Execute auto-tuning. (Refer to 6-8-1 Motor Off-line Auto-tuning on page 6-65.)

Then set the rated current value of the motor at 1st Motor Electronic Thermal Level (F11).

Set the value correctly according to the motor in use.

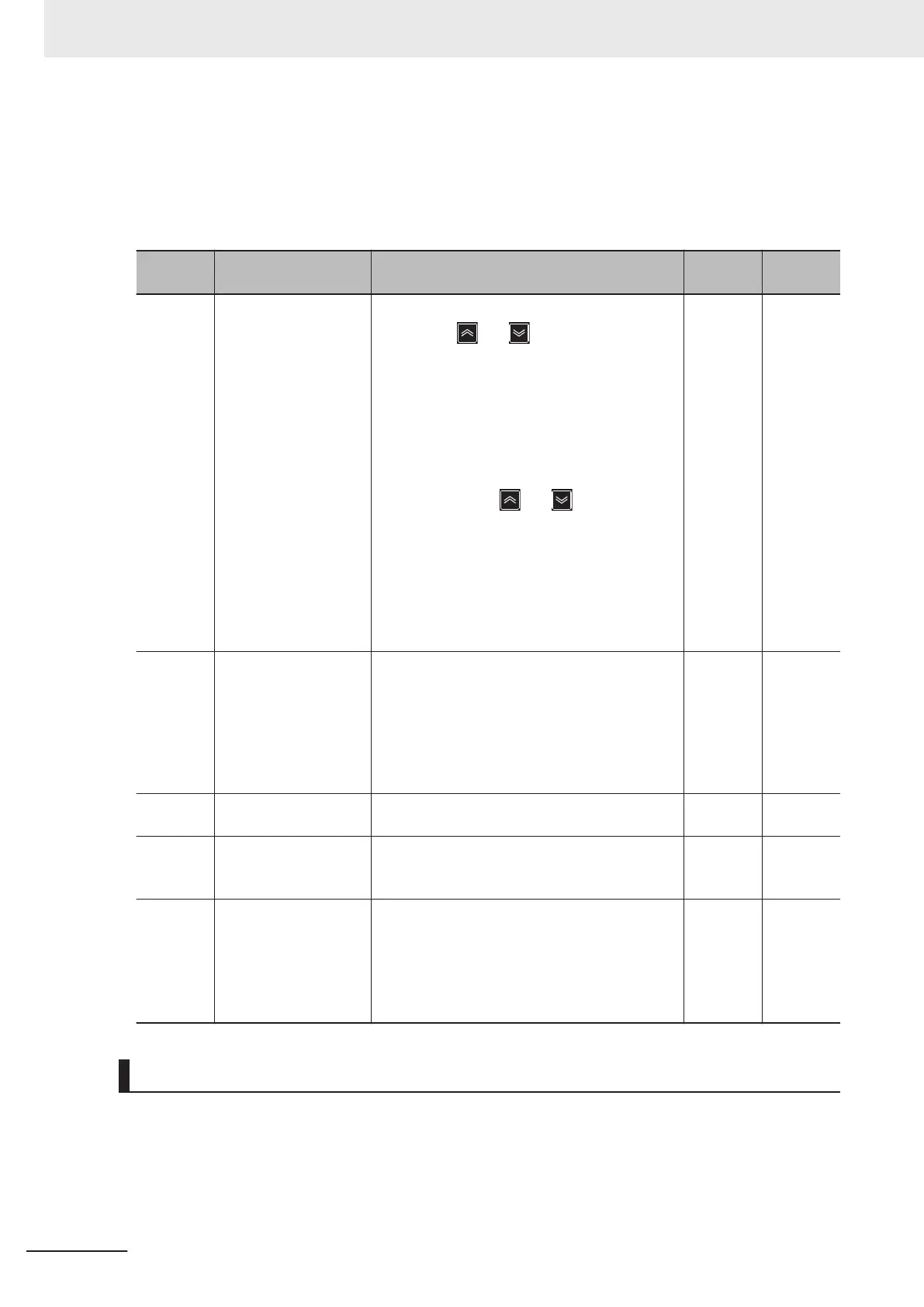

Parame-

ter No.

Function name Set value

Default

data

Unit

F01 1st Frequency Refer-

ence Selection

0 to 15

0 -

0: Operator ( and keys)

1: Analog voltage input (terminal AI1)

2: Analog current input (terminal AI2 (AII))

3: Analog voltage input (terminal AI1) + analog

current input (terminal AI2 (AII))

5: Analog voltage input (terminal AI2 (AIV))

7: UP/DOWN control

8: Digital Operator (

and keys) (balance-

lessbumpless switching available)

10: Pattern operation

12: Pulse train input

13: Calculation result

14: RS-485 communication

15: Fieldbus (Reserved)

F02 1st RUN Command

Selection

0: Operator (Direction of rotation input: terminal

block)

1: External signal (Digital input)

2: Operator (Forward rotation)

3: Operator (Reverse rotation)

4: RS-485 communication

5: Fieldbus (Reserved)

2 -

P01 1st Motor Pole Num-

ber

2 to 128 poles

4 Pole

P02 1st Motor Capacity 0.01 to 1000 kW Depend-

ent on ca-

pacity

kW

F11 1st Motor Electronic

Thermal Level

0.00 ; 0.01 to 118.8

0.00 : Disable

0.01 to 1

18.8 A

* Setting range from 1%(HHD) to 135%(ND) of

the rated inverter current.

Depend-

ent on ca-

pacity

A

No-Load Run

In a motor no-load state (not connected to the mechanical system), rotate the motor via the Digital Op-

erator.

Forward/reverse rotation via Digital Operator

Follow the steps below to rotate the motor in the forward or reverse direction via Digital Operator.

3 Operation and Test Run

3-20

M1 Series Standard Type User's Manual (I669)

Loading...

Loading...