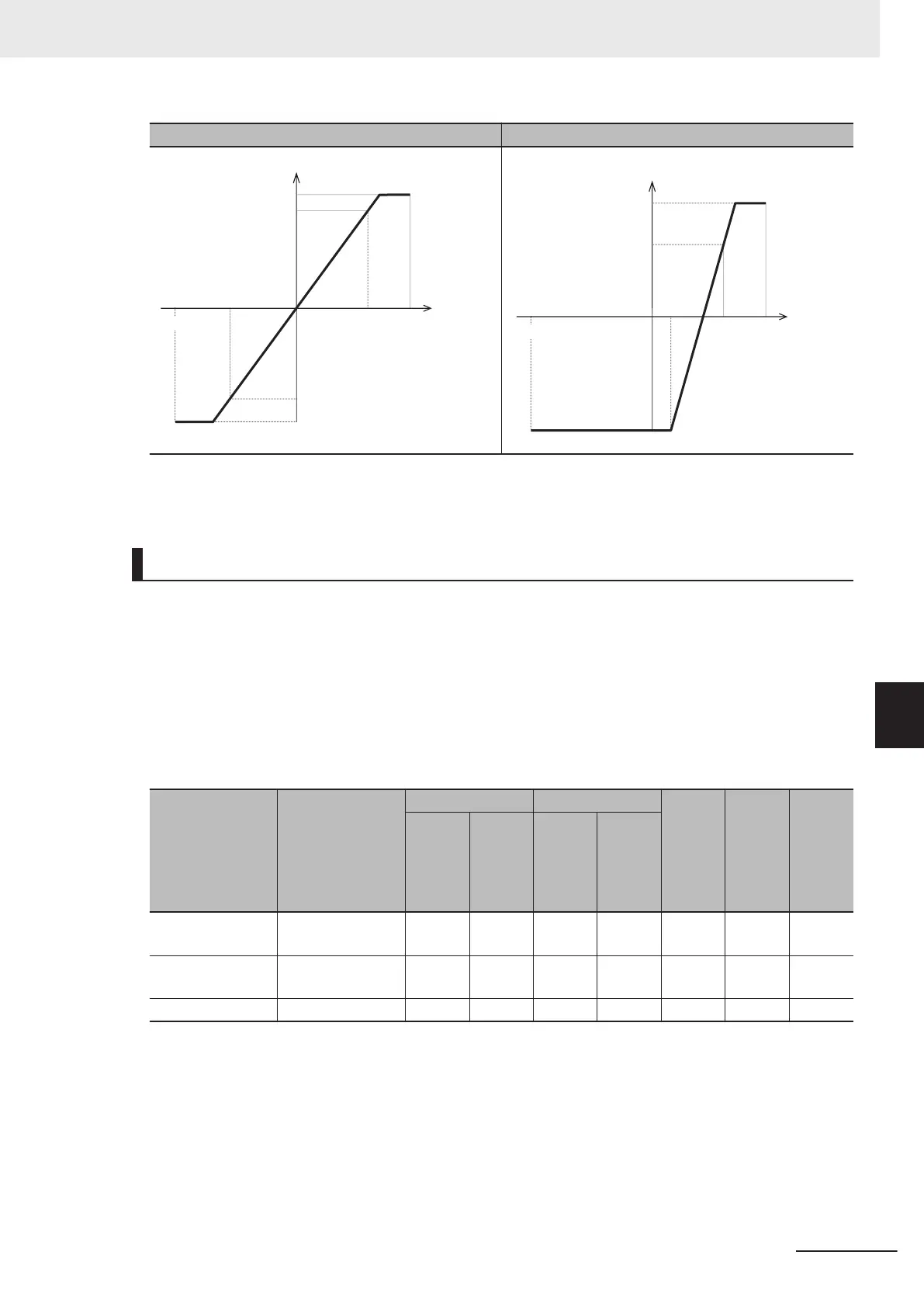

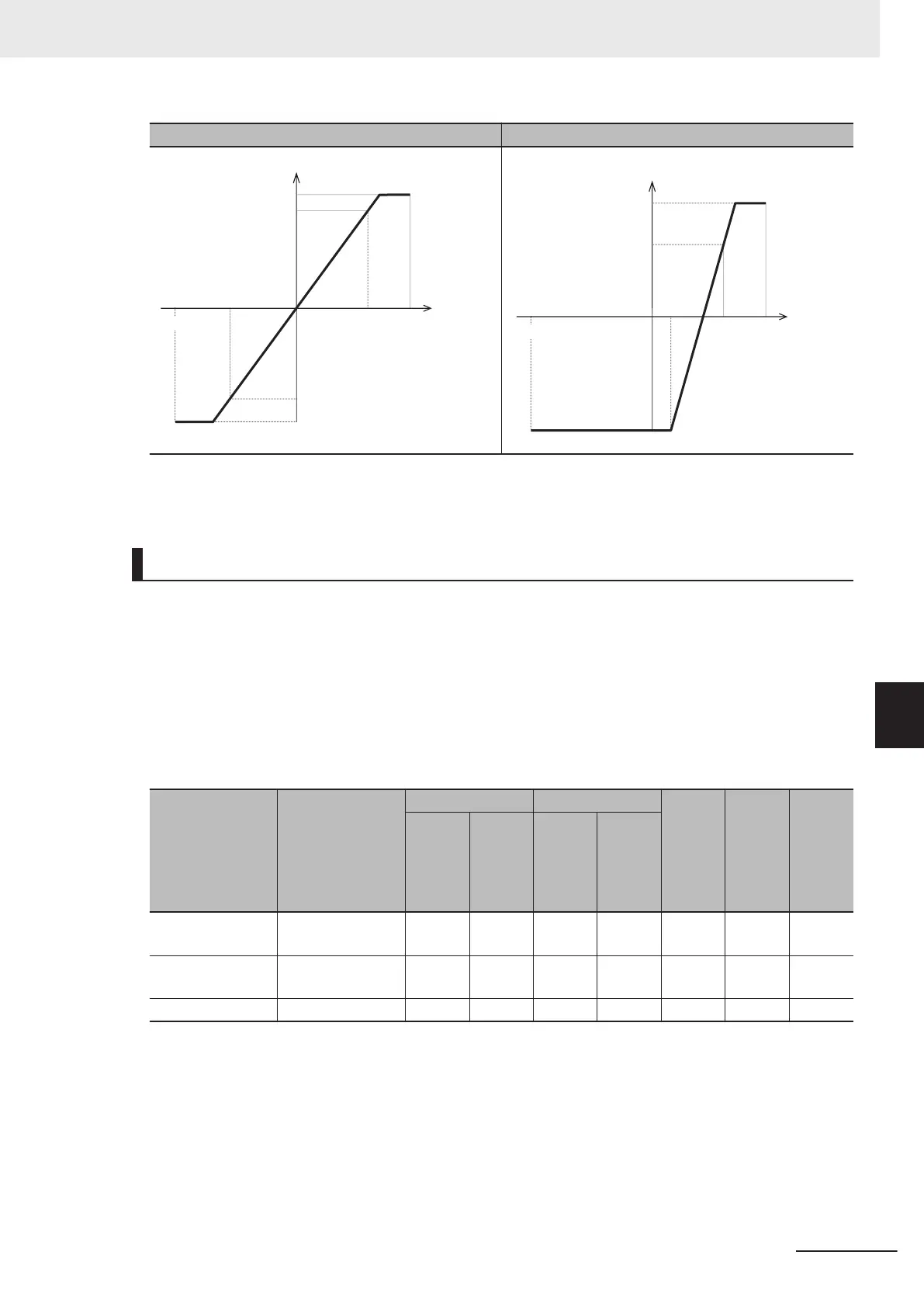

Bias = 0%, Bias base point = 0% Bias ≠ 0%, Bias base point ≠ 0%

PID process command

100%

Gain

0%

B point

100%

Analog

input

Gain

base point

-100%

-100%

PID process command

100%

Gain

Bias

0

%

B point

A point

100%

Analog

input

Bias base

point

-100%

Gain

base point

• PID command by communication (J02 = 4)

Communication parameter (S13): T

ransmission data 20000d/100% PID command.

PID Control Feedback Selection (E119)

• E119 = 0: Analog input terminal

If 0: Analog input terminal ([AI1], [AI2] AII function, [AI2] AIV function) is selected for PID Control

Feedback Selection (E1

19), allocate “5: PID feedback value” to the terminal used in feedback input

by any one of E61, E62 or E63. The analog input value is internally controlled as 0% to 100%. For

details on analog input, refer to 7-3-1

Analog Input Function Selection on page

7-35.

When analog input is applied to PID feedback, the following gains, biases, filters and offsets are appli-

cable.

Input terminal Input range

Bias Gain Polari-

ty se-

lection

(Range

selec-

tion)

Filter Offset

Bias

Base

point

Gain

Base

point

AI1

0 to 10 V, -10 to

10 V

C55 C56 C32 C34 C35 C33 C31

AI2 (AII function)

4 to 20 mA, 0 to

20 mA

C61 C62 C37 C39 C40 C38 C36

AI2 (AIV function) 0 to +10 V C67 C68 C42 C44 C45 C43 C41

• E119 = 2: Modbus communication

If “2: Modbus communication” is set to PID Control Feedback Selection (E119), set a value in com-

munication parameter (S30) under the assumption of 20000d = 100%.

• E1

19 = 3: Pulse train frequency

If “03: Pulse train frequency” is set to PID Control Feedback Selection (E119), the inverter captures

a value converted into a percentage with the maximum frequency as 100% where the correction fac-

tor (d63/d62) is multiplied with the frequency value [kP/s] of the captured pulse train input.

7 Other Functions

7-131

M1 Series Standard Type User's Manual (I669)

7-9 Other Operation Functions

7

7-9-13 PID Function

Loading...

Loading...