Workshop Manual, TSD3450E, Issue 1 103

11

2800

Fuel system 11

General information

The fuel supply circuit used on the 2806 engine is a conventional design for engines fitted with unit injectors.

A fuel transfer pump, driven by the timing gears of the engine, is fitted behind the gear case on the left side of

the engine. The fuel transfer pump draws fuel from the fuel tank. The fuel is filtered by the primary fuel filter

before it enters the transfer pump. From the transfer pump, the fuel is filtered by the secondary fuel filter and

is then supplied to the fuel gallery in the cylinder head. The fuel injectors draw fuel from the gallery and return

the spill fuel to the same gallery. A pressure relief valve ensures that the pressure in the gallery is maintained

and any excess fuel is returned to the fuel tank.

Each unit injector is operated, through a rocker lever, by a lobe of the camshaft. This provides the force

required to pressurize the fuel in the injector. The camshaft has three lobes for each cylinder, the other two

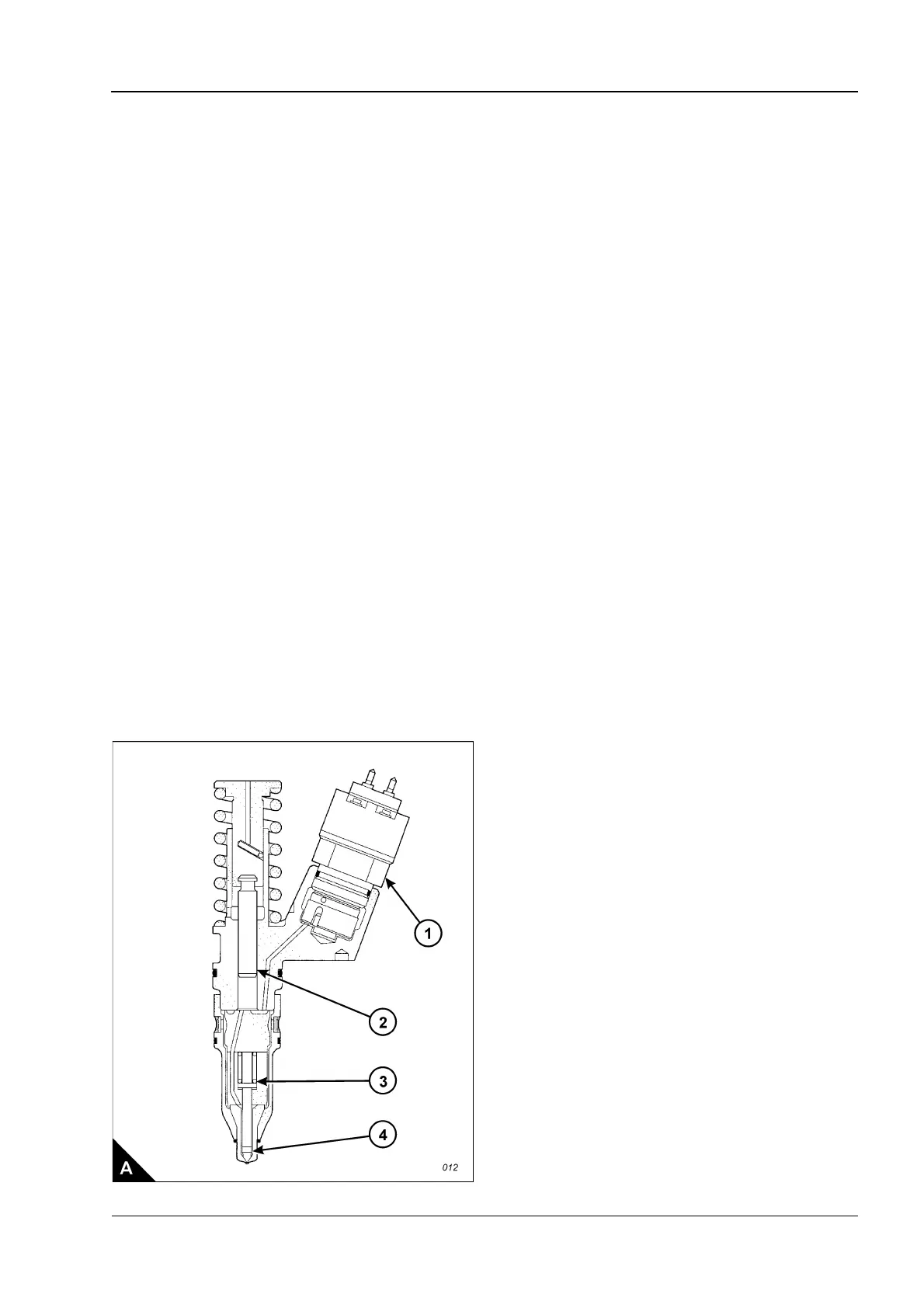

lobes operate the inlet and exhaust valves. The unit injectors are fitted with a solenoid (A1) which is

electronically controlled by the ECM (engine control module).

Low pressure fuel circulates through the body of the unit injector and excess fuel is returned to the fuel gallery

through a spill port. When the solenoid of the unit injector is activated by a signal from the ECM, it closes the

escape route for the fuel and the pressure increases in the injector tip (A4).

Injection begins when the pressure in the tip reaches 34464 kPa (5,000 lb/in

2

). At this pressure the force

applied by the spring (A3) is not sufficient to keep the nozzle closed. As the plunger (A2) moves through its full

stroke, the pressure increases. When the correct amount of fuel has been injected, the ECM de-energises the

solenoid. This opens the spill port and the reduction in pressure allows the spring (A3) to close the injector

nozzle. The high-pressure fuel which passes through the spill port returns to the fuel gallery.

During maintenance of the fuel system, clean thoroughly each component before it is removed or dismantled

and fit suitable caps and plugs to all unions immediately after they have been disconnected.

Operations for the unit injectors and the injector sleeves are given in Chapter 3 Cylinder head assembly.

Loading...

Loading...